The CCD online error page detection system is installed on post-press binding equipment (saddle stitching, hardcovering, folding machine, book sewing machine, book mounting machine, etc.). By installing an industrial camera at the paper feeding position of each workstation, each paper of the book is photographed, and the image is processed by software to determine whether there are any bad conditions such as wrong pasting, missing pasting, and white pages. When a bad condition is found, a shutdown alarm signal is output in time (some models can be connected to automatic waste discharge) for manual elimination of problematic materials and reset to restart the operation, so as to ensure the accuracy of the page number sequence of each book and the absence of white pages. As the last link in book binding, the high-speed and stable operation of the system ensures the production yield, eliminates the production of defective products, eliminates such customer complaints, and greatly improves the production efficiency of the printing plant.

Performance and characteristics of page error detection equipment

1. The detection system and the machine are connected (alarm shutdown or automatic waste discharge)

2. The system interface is simple, easy to operate, one-click modeling, and the detection accuracy is adjustable.

3. The system is stable and reliable, and can adapt to high-speed, high-intensity, and harsh environmental applications.

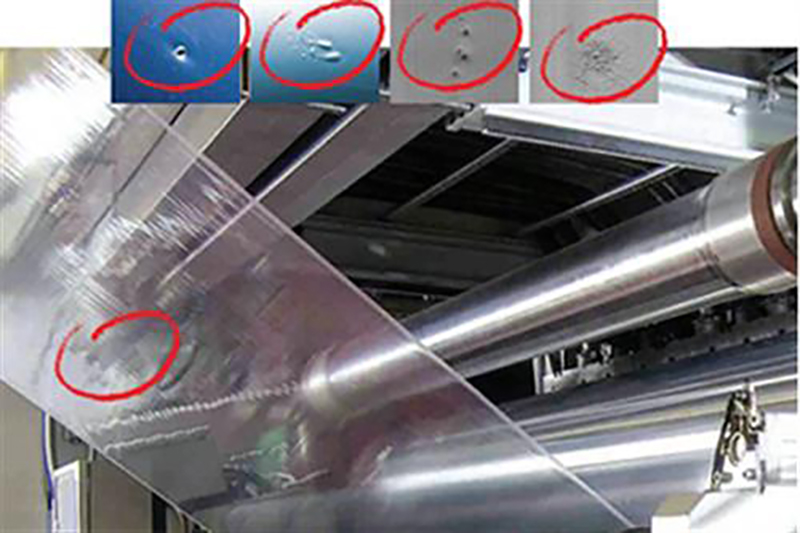

4. Suitable for detection of overboard paper, blank pages, wrong pages, reverse pages, graphics, and character mixing.

5. Reduce labor costs, improve automation and efficiency.

6. The maximum detection speed can reach 1000 pages per minute.

Applied industry

Printing factory, packaging factory

Machine structure

| Camera | Sony |

| Lens | FA High Definition Optical Industrial Lens |

| Sensor | pepperl-fuchs |

| Light source | Customized optical adaptive light source |

| Computer | Industrial computer |

| Inspection spectrum | A3 |

| Inspection speed | Max 1000pcs/min |

| Inspection software | Intsoft Tech |

| Signal output | Intsoft Tech customized module |