Advantages of machine vision

The surface defects of industrial products seriously affect the quality of quality, especially nowadays, technology is becoming more and more developed. If the product has a defect, it directly affects the brand’s influence, and how to avoid surface defects and other quality problems of the product?

Traditional manual inspection is expensive, easy to fatigue inspectors, as well as easy to detect missing and other disadvantages. It has been difficult to adapt to the high-speed production system. Surface visual inspection in the industry has become more mature, as surface defect detection provides many new solutions.

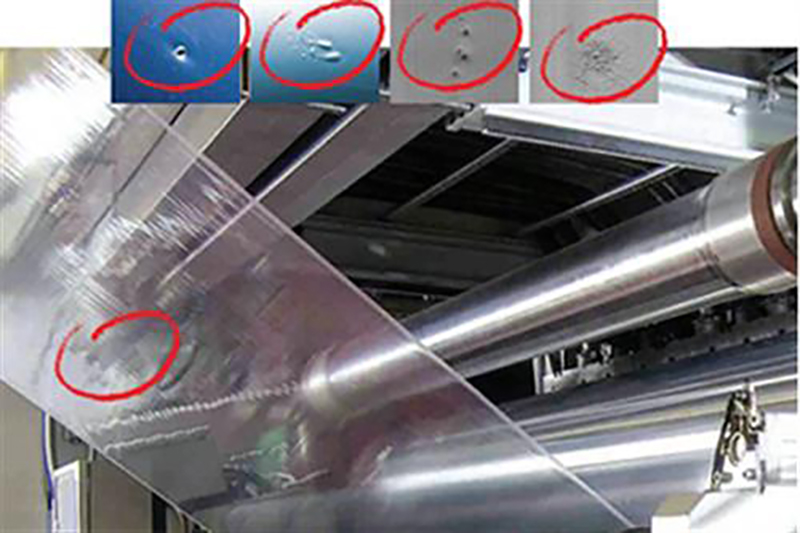

Plastic film surface inspection

Plastic film surface defect detectors integrate many advanced technology applications in the field of machine vision, and incorporate a number of innovative detection concepts, can be seamlessly connected to the existing production line real-time online detection, but can also be detected offline, in the surface of film defects as well as semi-transparent film internal defects for rapid detection at the same time to generate visualized feedback to the production data report. In addition, accurate, stable and fast detection can be used to improve production flexibility and automation, significantly improve automation to improve production efficiency, and facilitate information integration.

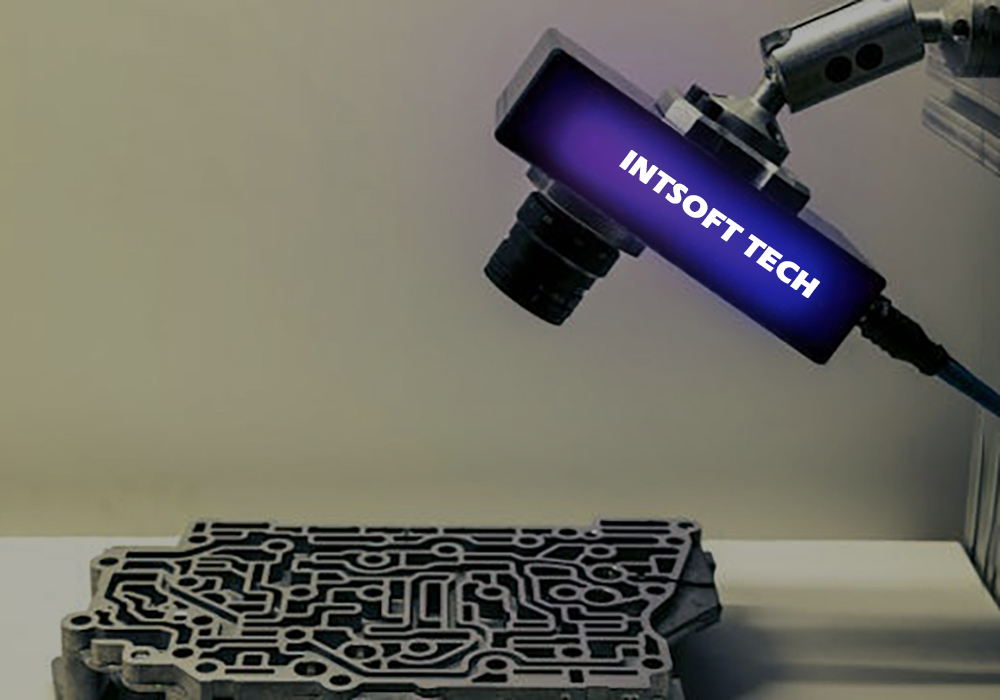

Machine vision is the use of machines instead of the human eye to make measurements and judgments. The output of the vision system is not an image video signal, but the detection results (e.g., data such as defects, dimensions, etc.) after arithmetic processing.

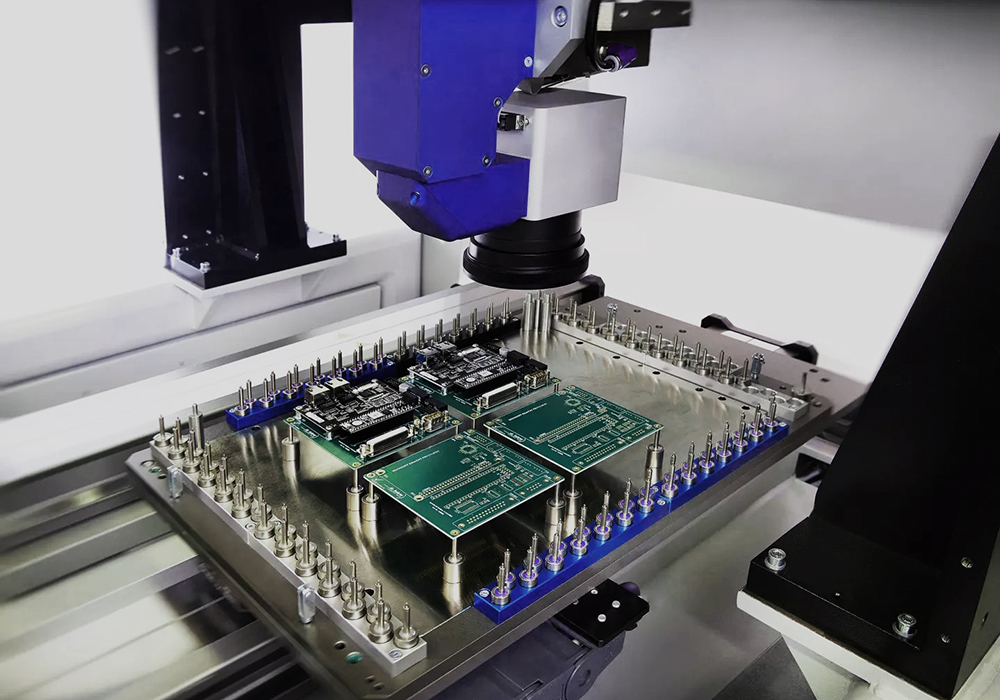

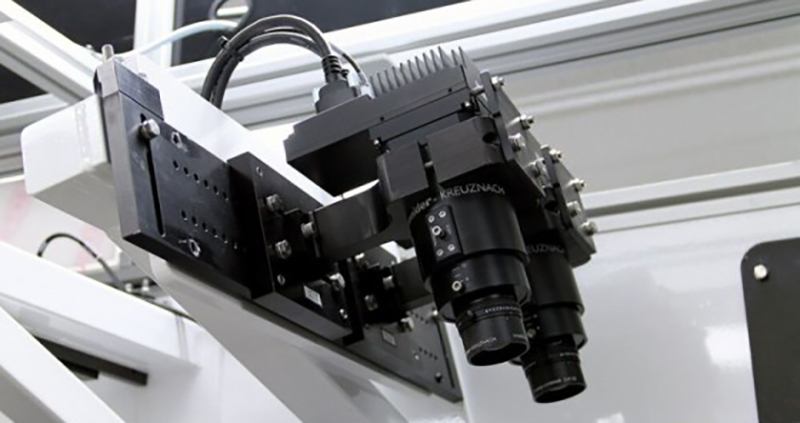

Intsoft inspection system uses a CCD camera to convert the target to be captured into an image signal, which is transmitted to a dedicated image processing system and converted into a digital signal according to pixel distribution and information such as brightness and color.

The imaging system performs various operations on these signals to extract features of the target, such as area, length, number, position, etc. The results are then output according to preset tolerances and other conditions, such as type of defect, size, angle, offset, number, pass/fail, and so on. The upper computer (e.g. PC and PLC) obtains the inspection results in real time, and then commands the motion system or I/O system to perform the corresponding control actions (e.g. positioning and classification).

Case study of plastic film defect detection

The following are some of the parameters Intsoft use to detect film defects.

Main technical indicators:

1. Measurement accuracy: 0.1mm or more spots, stains, holes and other defects;

2. Applicable width: customized according to requirements.

3. CCD quantity: according to the width of the measured object and the detection accuracy decision.

4. Detect common defects, process defect information, real-time defects to provide location, size, and records for users to refer to for inspection.

5. The system can set the parameters of the fault alarm, users can set the alarm line according to the production requirements, realize the sound and light alarm and mark the unqualified position online.