The sports watches we usually wear, most of the straps are made of silicone or rubber. Because in sports, our hands move with a large range of motion, and close contact with the hand skin of the strap is also required to be soft material, so as not to damage the skin. These qualified watch bands are generally beautiful in appearance, with pure colors and smooth surfaces. But since plastic products are notoriously prone to defects, how do these beautiful watch bands achieve such perfection? In addition to focusing on the production process during the injection molding of the watch bands, the use of machine vision defect detection equipment during the finished product inspection stage to eliminate 99.9% of defective products is also essential.

Following is the case study of watch strap defect detection sharing by Intsoft Tech.

Detection Content

| No. | Detection position | Method | Detectable or not |

| 1 | Length of strap | Positive light detection | YES |

| 2 | Width of strap | Positive light detection | YES |

| 3 | Clip hole diameter | Positive light detection | YES |

| 4 | End ring diameter | Positive light detection | YES |

Machine structure

Model: YTD-T300customized detection machine

Overall dimension: 900*800*1850mm

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Barsler industrial camera | 1 sets | |

| 5 | Camera adjustment module | Intsoft customized | 1 sets | |

| 6 | Industrial lens | FA HDV optics industrial lens | 1 sets | |

| 7 | Light source | Custom optical adaptive light source | 1 sets | |

| 8 | Detection platform | Intsoft customized | 1 sets |

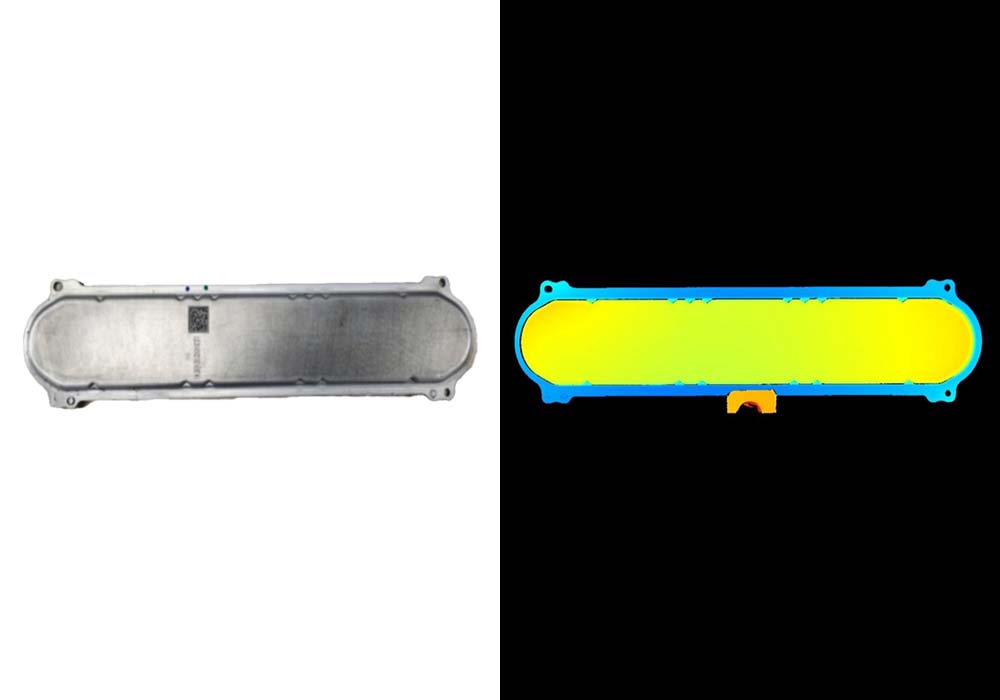

Image of detected product

Strap dimension measurement

positive light detection good product analysis image: Ok, length: 117.764 width: 16.323 —

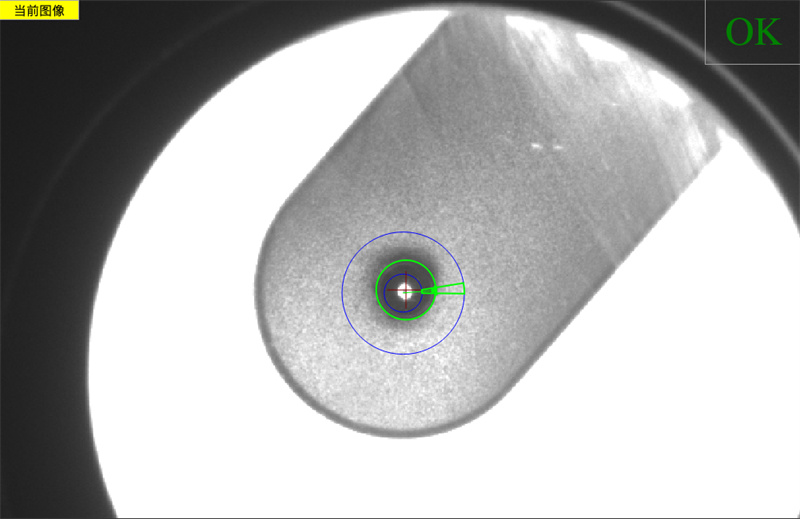

Clip hole surface defect detection —

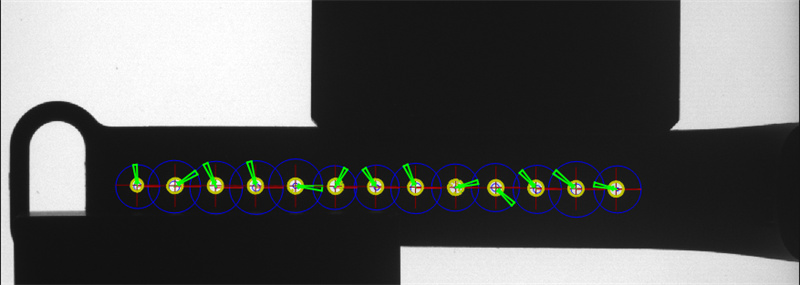

Clip hole dimension measurement —

| Hold | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Dia. | 1.628 | 2.030 | 2.005 | 2.009 | 2.003 | 1.959 | 1.997 |

| Hold | 8 | 9 | 10 | 11 | 12 | 13 | |

| Dia. | 1.968 | 1.990 | 2.017 | 2.014 | 2.015 | 2.007 |

System installation requirements

Equipment placed in the inspection space: In the assembly line side of the installation of Intsoft vision inspection system alone, you need to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius.

Air humidity: 90% RH or less.

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA