At present, almost all positions in the mobile phone production line are automated. Before the back cover of the mobile phone is put on, there is another indispensable process, that is, inspection. To ensure that the assembly position of the mobile phone parts is correct, whether there are any missing accessories, whether the accessories are defective, whether the anti-counterfeiting label is affixed, etc., all must be completed in this step. It can be seen that defect detection is a crucial factor related to the quality of mobile phones.

The following case is from our mobile phone manufacturer client, who used our custom machine vision equipment to detect internal defects of mobile phones.

Detection items:

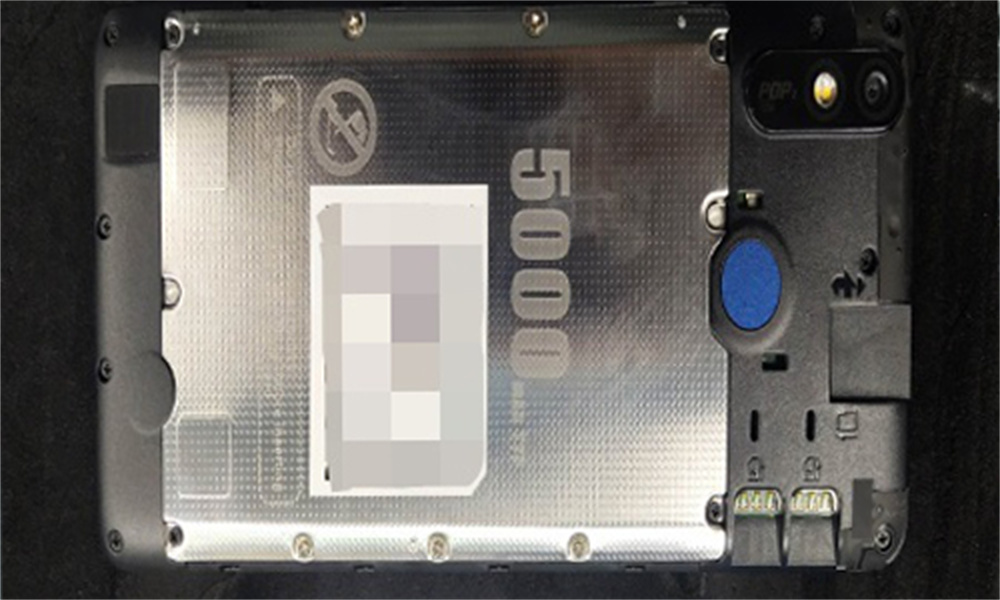

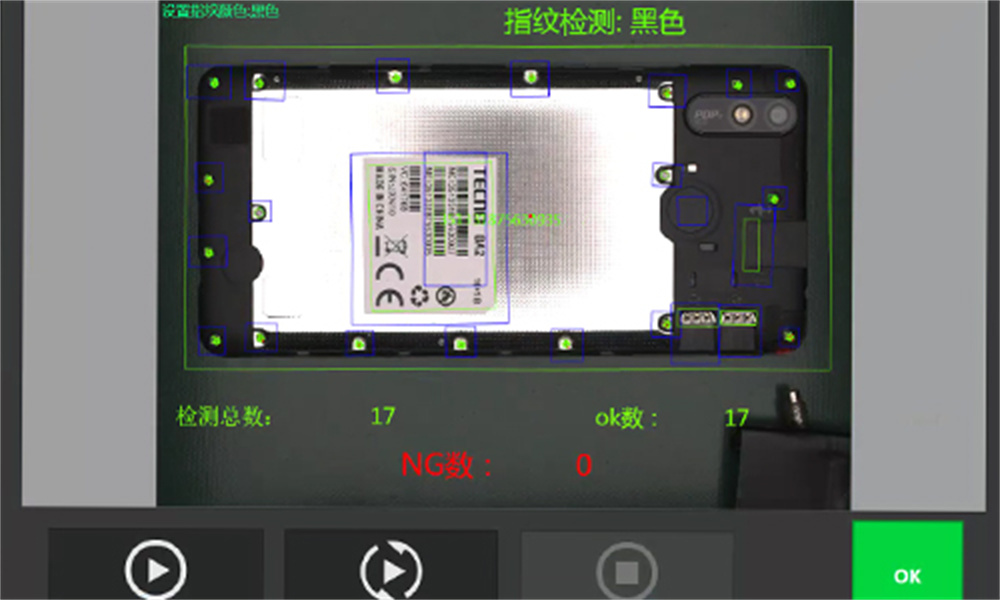

1. Check if phone body screws are missing, misaligned, scratched, or mixed with black and white screws

2. Check if the anti-tampering screw labels are missing, misaligned, damaged, or shifted.

3. Check if phone body tags are misaligned, missing, missing fonts, dirty surfaces, or misaligned.

4. Check if the SIM card and SD card used for testing are still in the card slot.

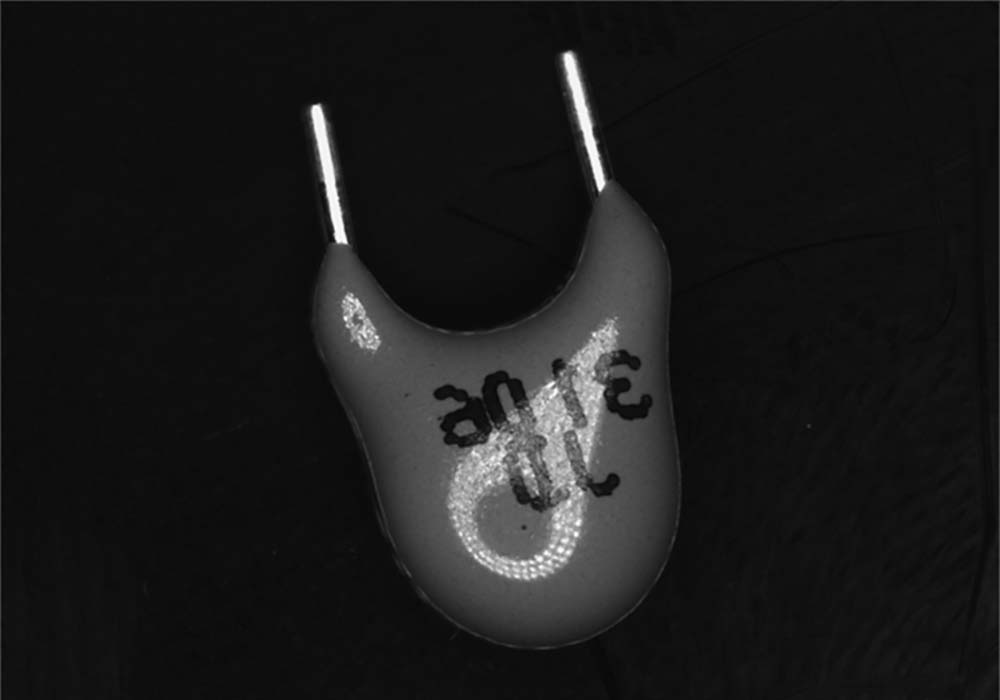

5. Check if the color of the fingerprint recognition area is abnormal.

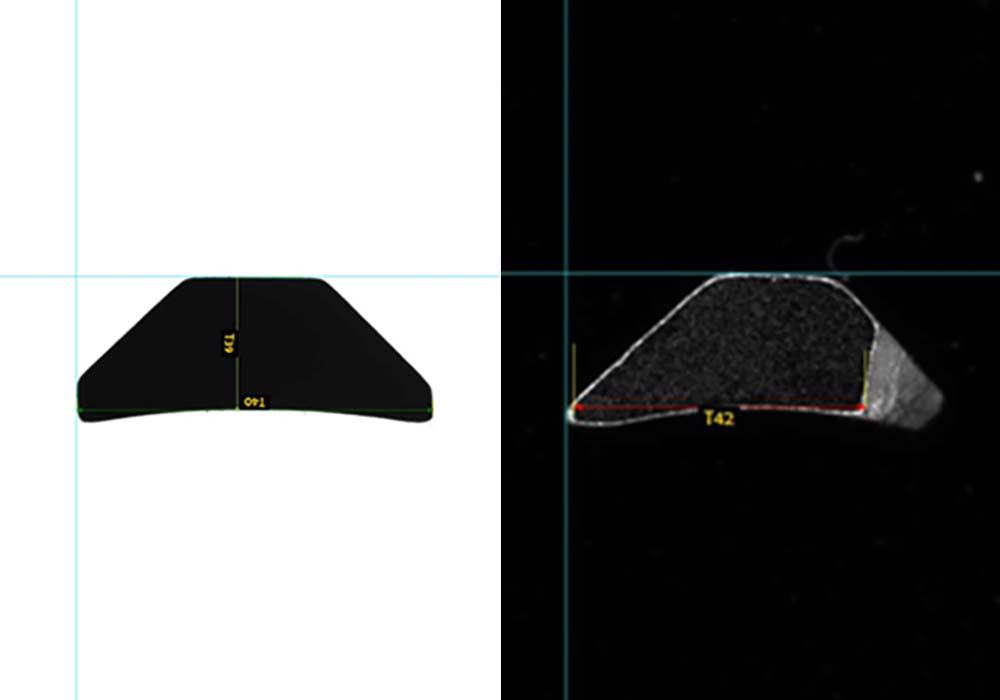

Then we use a high-resolution industrial camera and an industrial computer to detect the information returned. If there is a quality problem, an alarm signal will be sent, and the NG error position will be marked on the image data. Finally, the number of inspections and NG will be counted. Finally, the image of the defective mobile phone will be saved and marked, named with the barcode name+ time, and the specific location of NG will be shown in a red box. This solves the previous heavy pressure of manual inspection one by one, and improves efficiency and accuracy.