This is a washing machine detection equipment customized by Intsoft Technology’s washing machine manufacturer customer.

Our detailed machine vision detection solution is as follows:

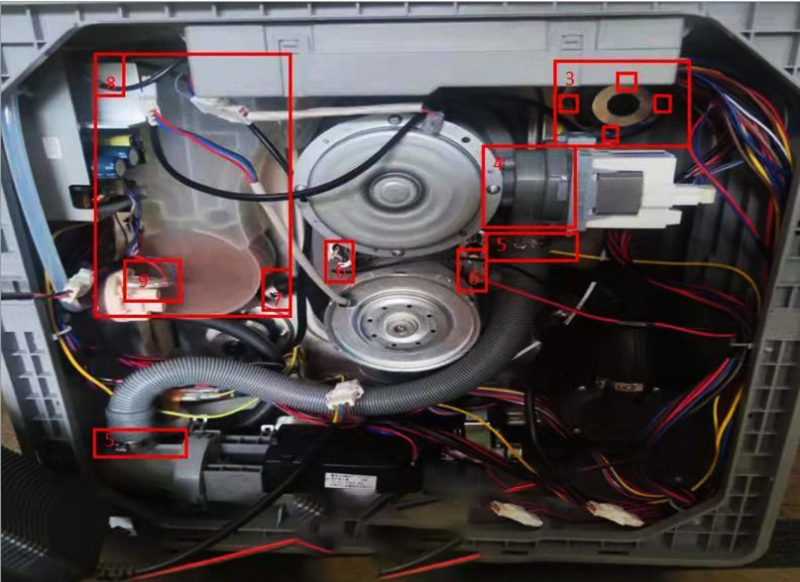

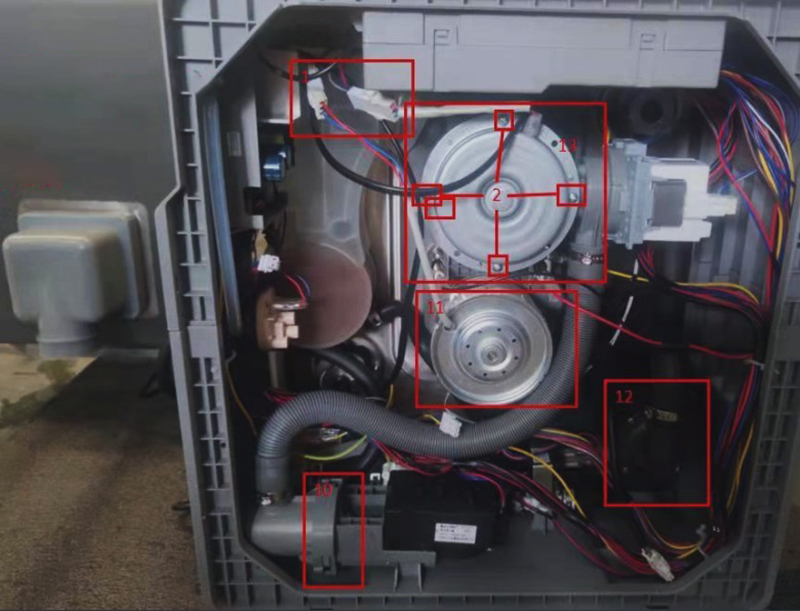

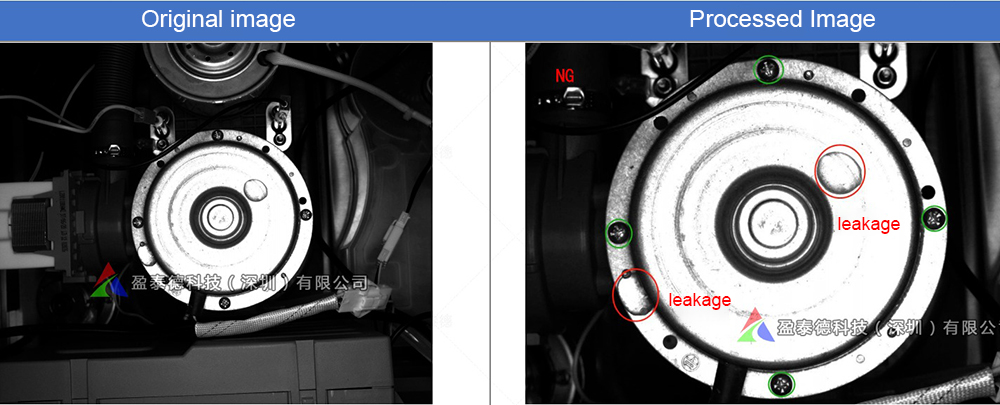

Vision detection items:

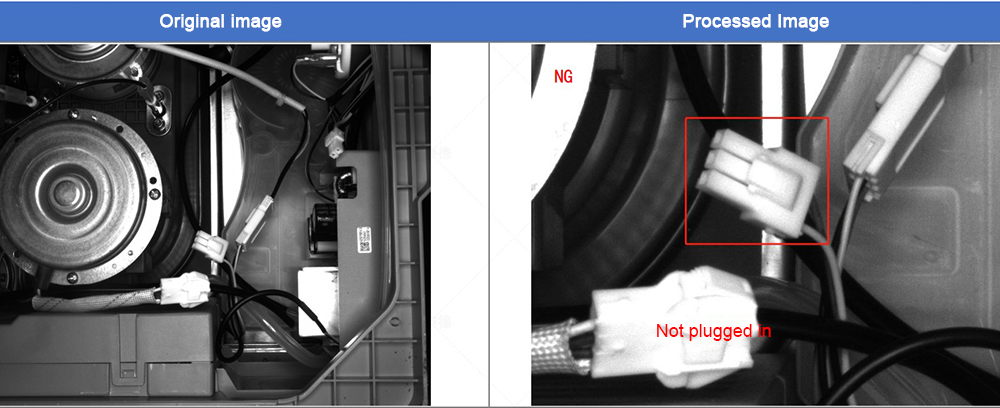

- 1. Wire harness not plug

- 2. Screw missing, not tightened, water seepage

- 3. Cracking, water seepage

- 4. The hoop is not tightly clamped, water leakage

- 5. The hoop is not tightly clamped, water leakage

- 6. Connector not plugged

- 7. Not clamped in place, water leakage

- 8. Cracking, water leakage

- 9. Wire harness plugged in reverse

- 10. Water seepage

Working process:

- Enter basic product information, take OK products for modeling, and set test data.

- Install the camera at a fixed position. When the product reaches the photoelectric sensor position, a trigger signal will be generated immediately. The camera will collect images and upload them to the database.

- After receiving the image information, Intsoft Technology visual recognition system will perform a series of processing, analysis, and good/bad product judgments, and the interface will output the test information in real time.

If the product is detected to be inconsistent with the preset data, an NG signal will be output; if the test is OK, the product will enter the next process according to customer requirements.

- According to the preset parameters, product detection and judgment are carried out. The detection parameters can be set in different areas to flexibly respond to different detection requirements of different areas of the same product;

Note: The product image must be clearly visible and within the field of view.

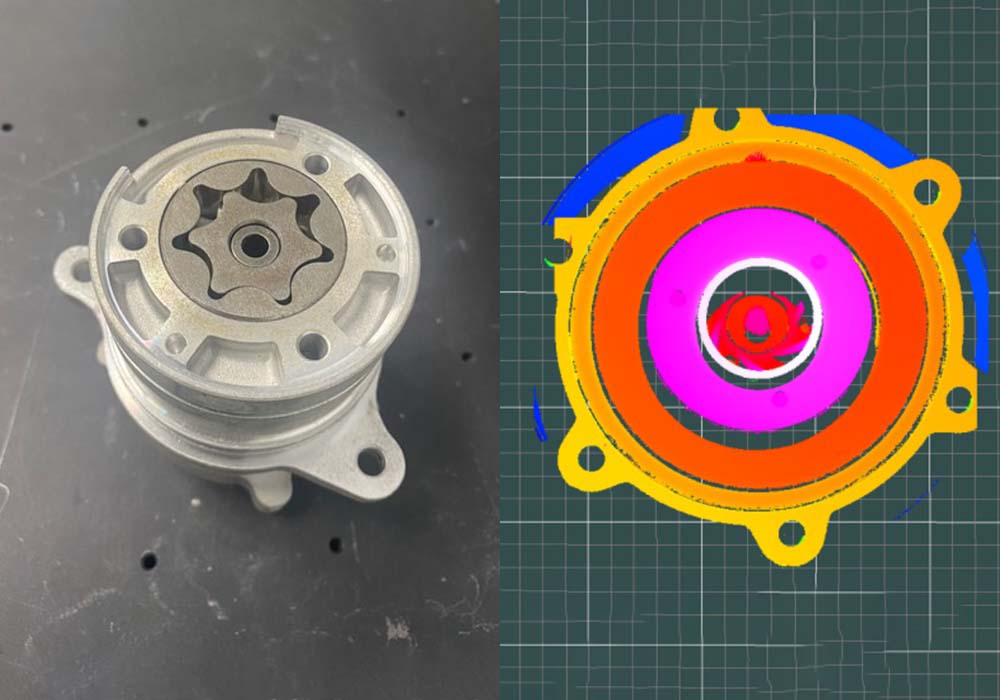

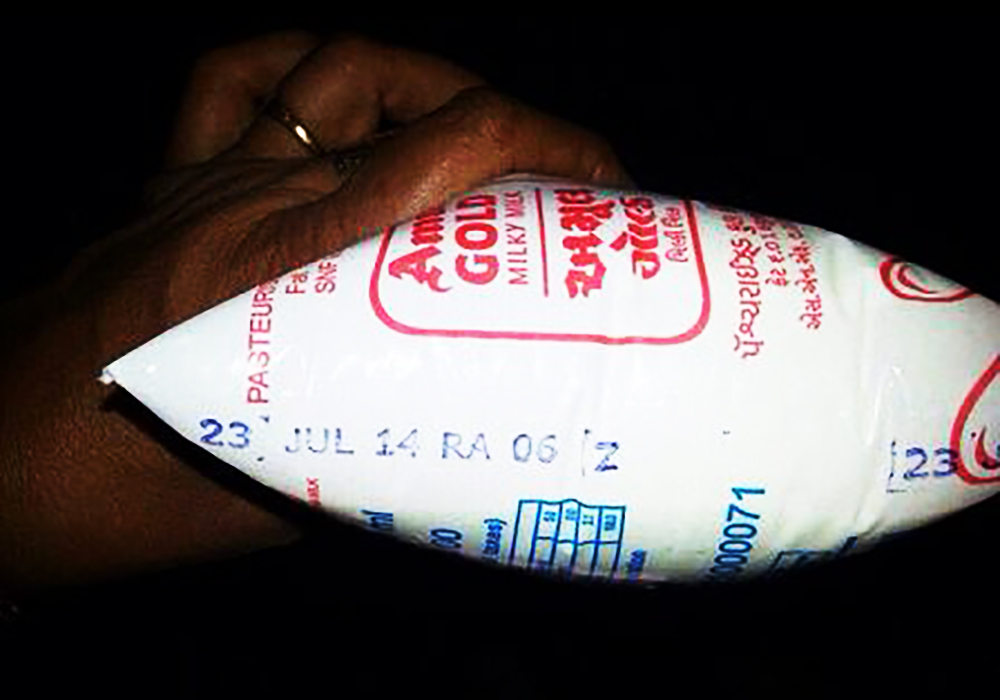

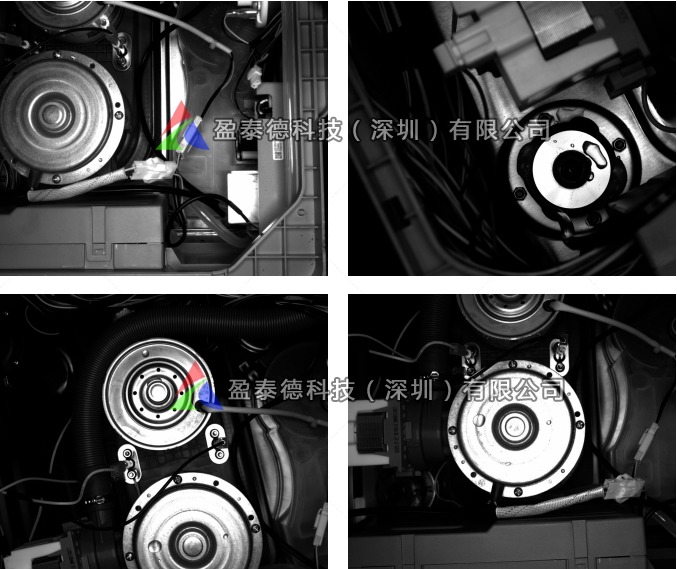

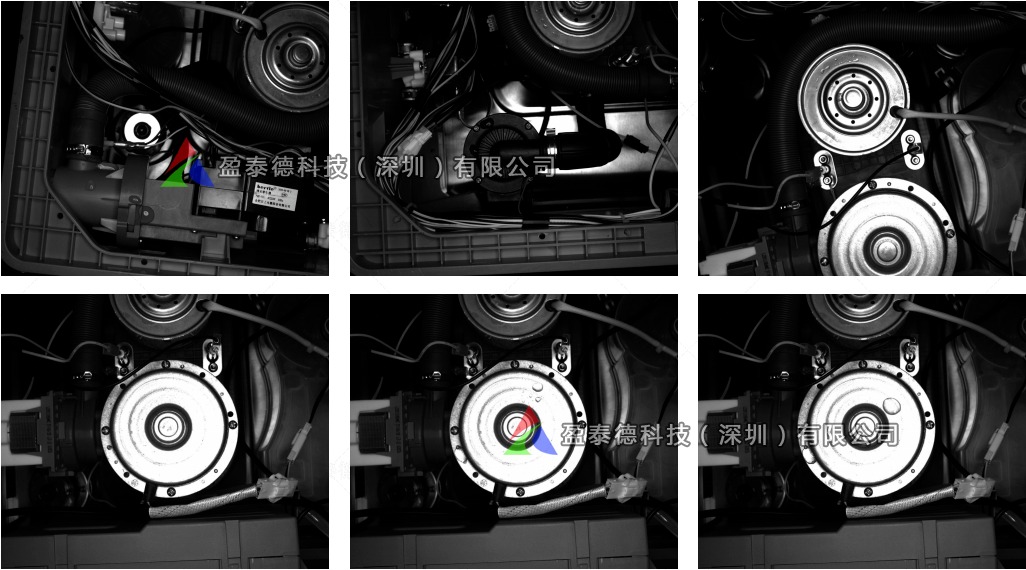

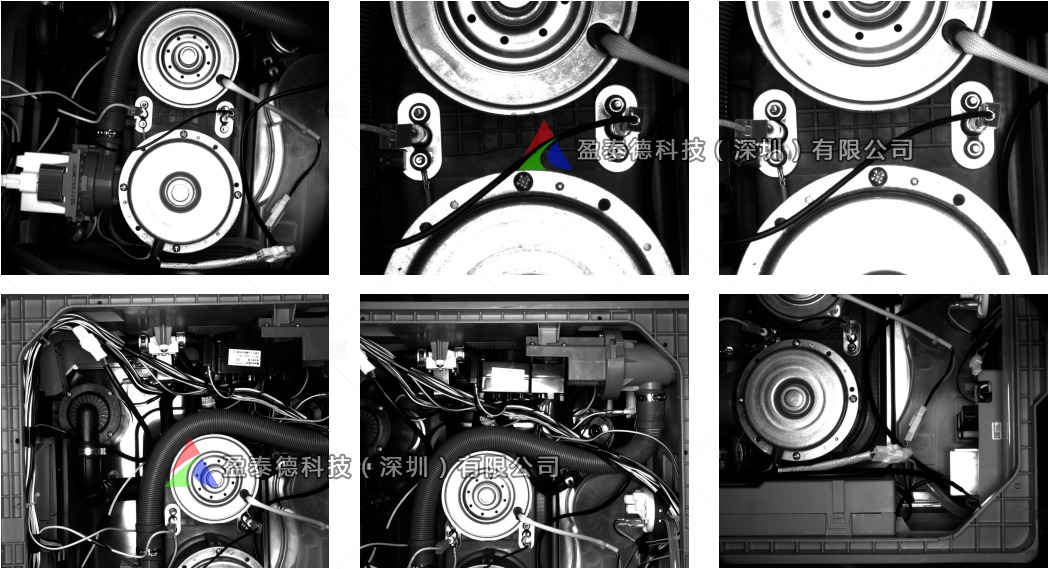

Partial image collection:

Process:

System functions:

- When the system detects a defect, it outputs an alarm signal.

- Real-time information display and record detection information.

- Provide special tools such as system parameter adjustment and image saving. The system interface is friendly, operable and intuitive.

- In order to ensure data security, the system is equipped with permission management. Only administrators with permission can modify the corresponding system parameters.

- According to the selected product inspection items, matching the inspection program, the inspection area can be adjusted according to the actual situation.

- Detection history records can be automatically counted, saved, queried, called and other functions.

- Automatic linkage of assemblelines, remote technical services, etc.