As the core component of the vehicle fuel system, the quality and performance of the automotive oil pump directly affects the safety, reliability and oil efficiency of the entire vehicle. However, a situation that is often faced is that the car leaks oil due to defects in the sealing gasket. Therefore, the quality inspection of foil pump parts is a key link that must be solved.

The traditional inspection method mainly relies on manual three-coordinate measurement, which is not only inefficient, but also difficult to ensure consistency of inspection results. With the continuous advancement of intelligent automotive manufacturing, customers are in urgent need of introducing more advanced automated inspection solutions.

Measurement items and technical requirements

In response to the specific needs of customers, we have carried out the following key inspection items for automotive oil pumps:

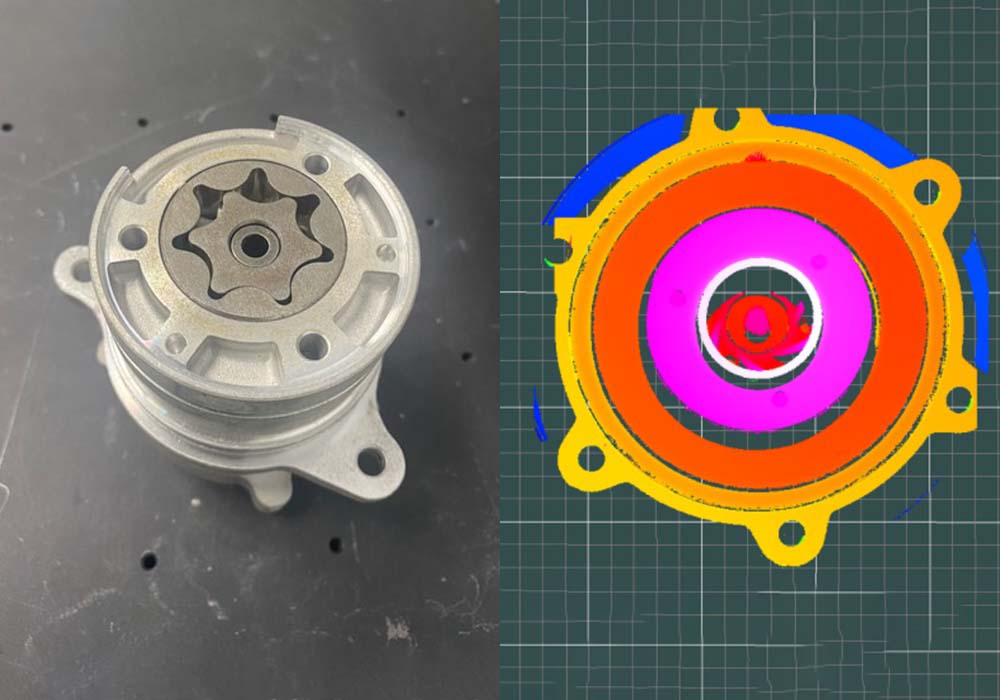

1. Detect whether there is a circular gasket in the “O” ring of the oil pump.

2. Detect the number of circular gaskets.

3. In order to ensure the accuracy and stability of the inspection results, the customer requires the inspection accuracy to reach ±0.05mm. At the same time, the entire inspection process must be fully automated to improve production efficiency.

Solution Design

Based on the above requirements, we designed a set of automatic inspection systems for automotive pumps based on machine vision:

1. Multi-angle visual acquisition: Through 3 high-resolution industrial cameras, high-definition images of different angles inside the oil pump are collected to ensure that all inspection targets can be fully captured.

2. Intelligent image processing: We have developed an image processing algorithm specifically for oil pump parts, which can quickly and accurately identify whether there are circular gaskets on the “O” ring and count their numbers.

3. Automated inspection process: The entire inspection process is fully automated without manual intervention. After the oil pump is placed, the system can automatically complete the steps of image acquisition, target recognition, data analysis, and output the inspection report.

4. Data management and traceability: Inspection results can not only be displayed intuitively, but also automatically stored in the database to support subsequent quality analysis and traceability.

Effects and Value

1. Through our machine vision solution, customers have fully automated the quality inspection of automotive oil pumps and achieved the following significant results:

2. Greatly improved inspection efficiency: replaced the cumbersome manual three-coordinate measurement, and the inspection speed increased by more than 3 times.

3. Significantly improve detection accuracy: detection accuracy reaches ±0.05mm, far exceeding customer requirements.

4. Ensure consistency of detection results: eliminate subjective differences caused by manual operation, and ensure high consistency of detection results.

5. Effectively prevent quality accidents: timely detection and isolation of defective products to prevent them from flowing into the vehicle production line, creating huge commercial value for customers.