Industry background and pain points

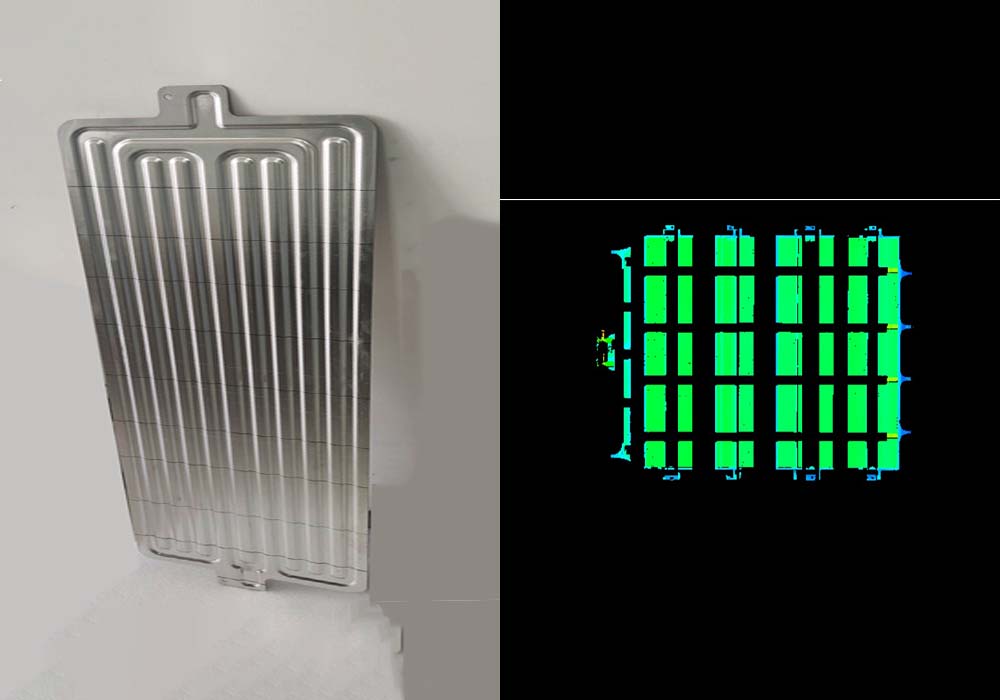

As the main trend of future automobile development, water cooling plates, a key component of new energy vehicles, play a vital role in ensuring the safety of power battery packs and improving driving range. The requirements for the quality of water cooling plate products are also getting higher and higher.

As a leading company in the global new energy thermal management industry, this new energy vehicle water cooling plate produced by our customer needs to undergo a comprehensive quality inspection, mainly including indicators such as flatness, breakage, position and aperture.

The traditional manual sampling method has problems such as low efficiency, poor accuracy and poor consistency, and it is difficult to meet the increasingly stringent quality control requirements. Therefore, customers urgently need to introduce advanced automated inspection solutions.

Inspection of objects and technical requirements

The customer entrusted us to carry out a comprehensive inspection of the water cooling plates of the new energy vehicles produced by it. The main inspection items include:

1. Flatness: Detect the flatness of the surface of the water cooling plate to ensure that it meets the design requirements.

2. Height difference of faults: Detect the height difference at the joint of the plate to avoid water leakage or other problems.

3. Position: Detect whether the hole position is accurate to ensure the accuracy of subsequent component installation.

4. Aperture: Detect the diameter of the cooling pipe connection hole to ensure flow performance.

In order to ensure the accuracy and consistency of the test results, strict requirements are put forward for the test accuracy, 80 microns in the X direction, and 30 microns in the Z direction.

Solution design

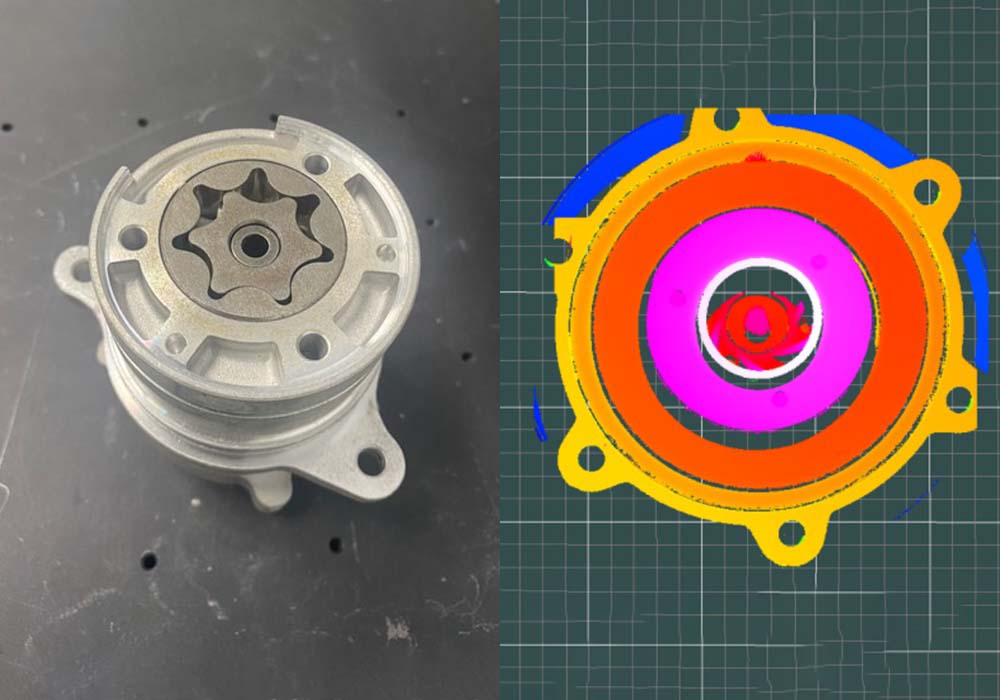

In response to the specific needs of customers, we designed a set of automated detection solutions based on machine vision:

1. Multi-camera module combination: Through the combination of 5 camera modules, the entire water-cooled plate can be fully scanned and inspected. The camera position and angle are carefully designed to ensure that the required inspection area can be fully captured.

2. Advanced image processing algorithm: We have developed an algorithm model specifically for water-cooled plate inspection, which can accurately measure key indicators such as flatness, height difference of faults, position and aperture, and compare and analyze test results with set tolerances to identify any deviations or defects in a timely manner.

3. Automated inspection process: The entire inspection process is fully automated without manual intervention. After the water-cooled plate is placed, the system automatically completes the steps of scanning, image processing, data analysis, and result output, greatly improvingpection efficiency.

4. Intelligent data processing: Inspection results can not only be displayed intuitively, but also automatically generate detailed test reports to support subsequent quality analysis and traceability.