Inspection content and requirements

Inspection workpiece area:

Inspection of samples with an overall height of 2.95*5.92mm

Inspection content:

1: Bottom inspection for cross head and cross recessed blocking

2: Side inspection for total height and thread outer diameter

Note: The image of above inspection items must be clearly visible for inspection

Inspection efficiency: 400-600 pieces per minute (depending on sample feeding speed).

Machine structure

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Barsler industrial camera | 2 sets | |

| 5 | Industrial lens | Intsoft customized | 2 sets | Fix focus telecentric lens |

| 6 | Professional glass disc | 1 sets | ||

| 7 | Solenoid valve | 360° detectable industrial camera | 1 sets | |

| 8 | Reducer | Customized optical adaptive light source | 1 sets | |

| 9 | Vibration mechanism | Professional Optical Glass Carrier | 1 set | |

| 10 | Feeding mechanism | Panasonic | 1 set |

Detection Process

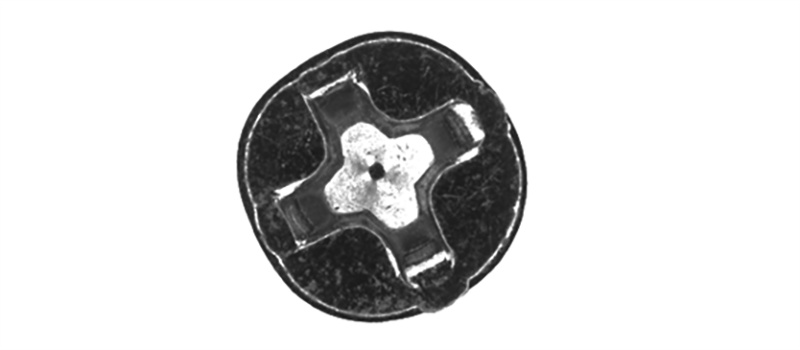

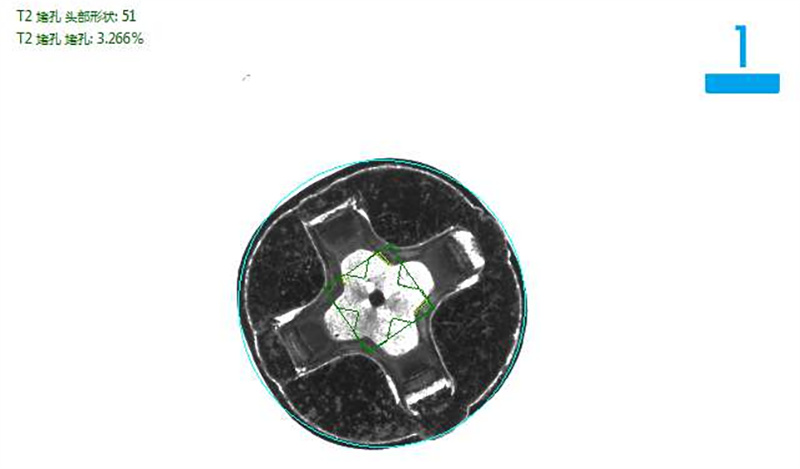

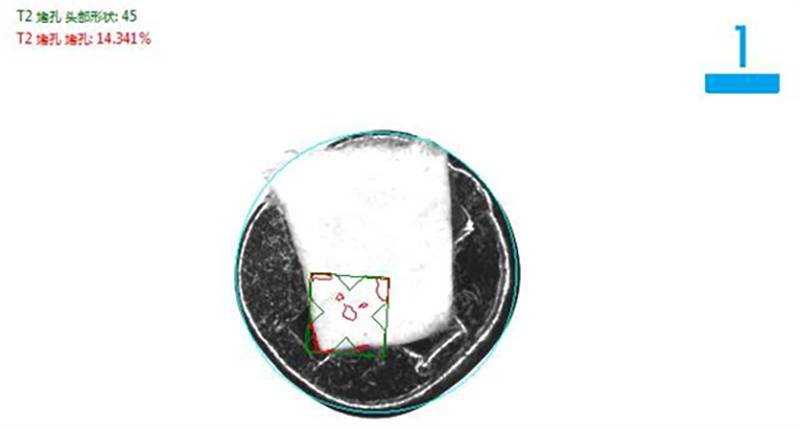

Bottom detection

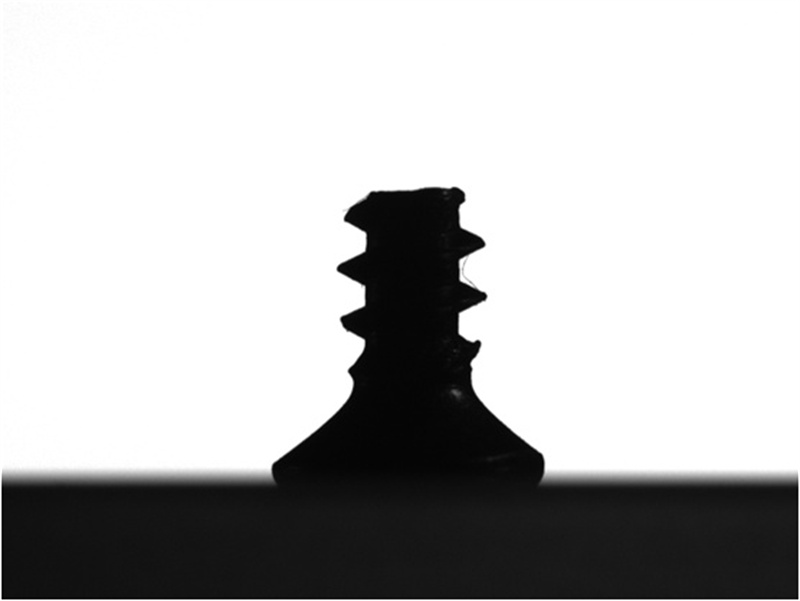

Original image:

Good product analysis image: OK

Defective product analysis image: NG cause of defect: Blockage

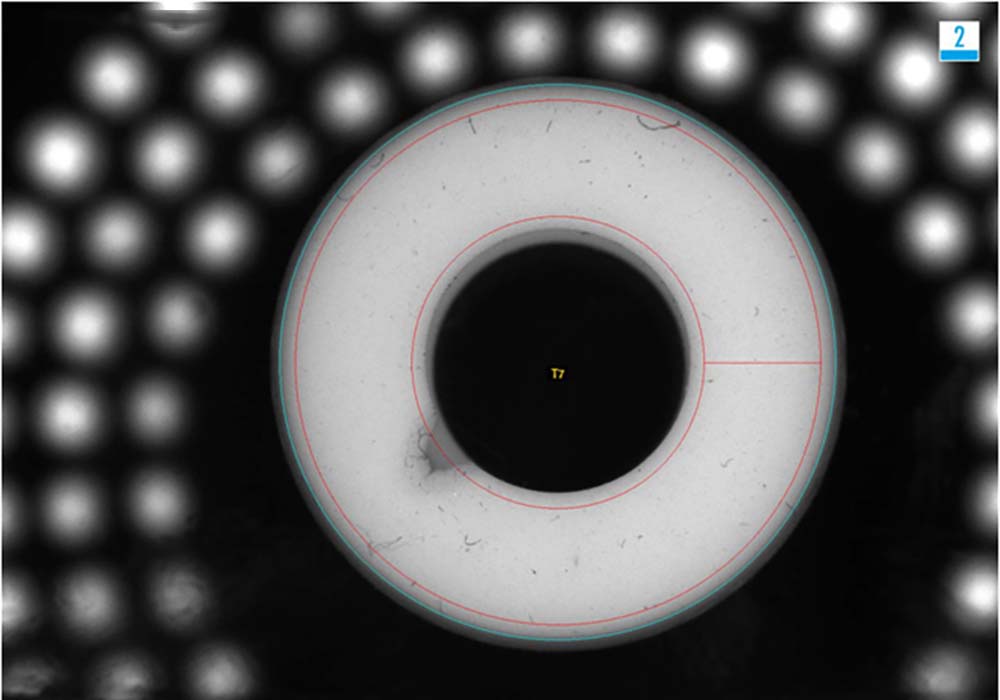

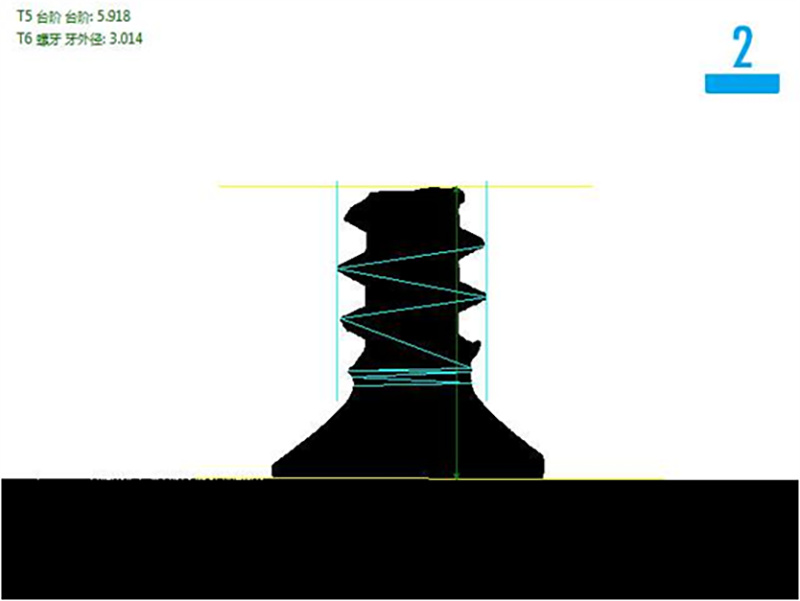

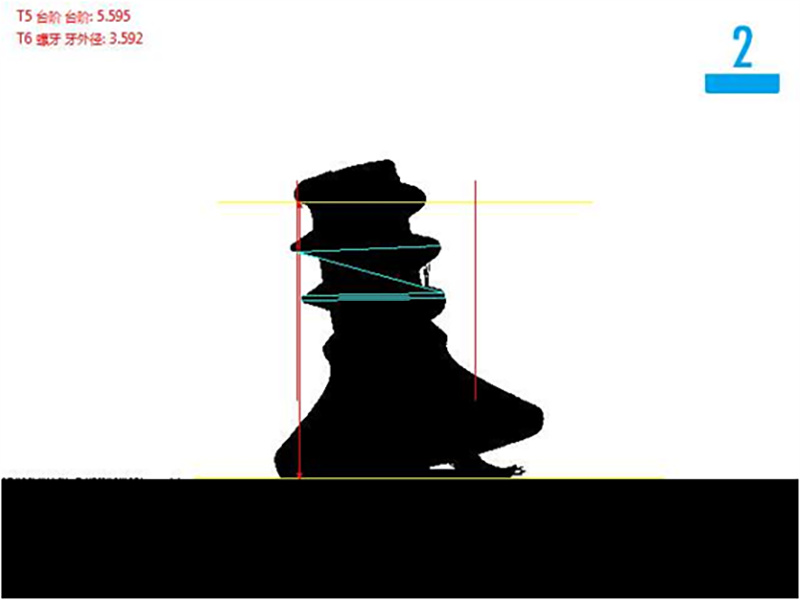

Side detection

Original image

Good product analysis image: OK

Defective product analysis image: NG cause of defect: Bottom uneven

System installation requirements

Equipment placed in the inspection space: In the assembly line side of the installation of Intsoft vision inspection system alone, you need to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: 90% RH or less;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA