Screws, nuts, and other hardware accessories are essential components in a wide variety of applications, from simple household items to complex industrial machinery. These small but critical components play a vital role in ensuring the structural integrity, functionality, and safety of the products and systems they are used in. Especially in the fields of aerospace, electronics, biomedical manufacturing, new energy and other industrial manufacturing, these accessories are more important.

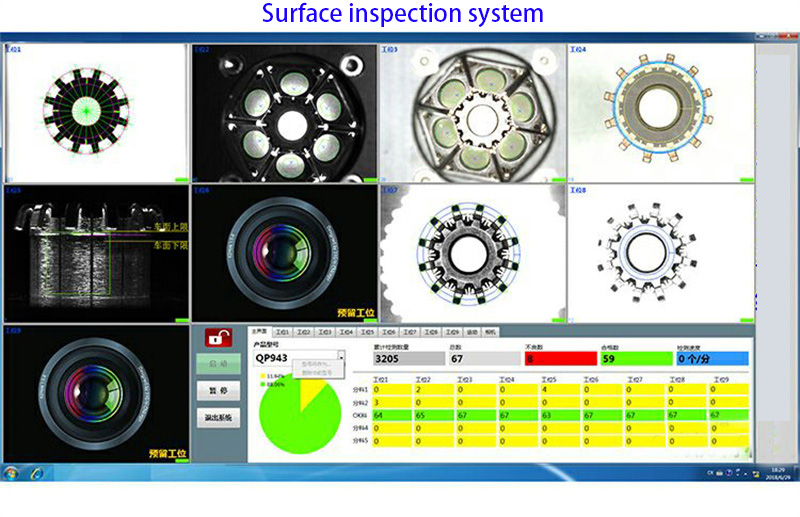

INTVision, an intelligent hardware visual inspection system developed by Intsoft Technology to solve hardware production problems, can solve problems such as hardware gears, cracks, whether the inner and outer diameters are concentric, and hole spacing.

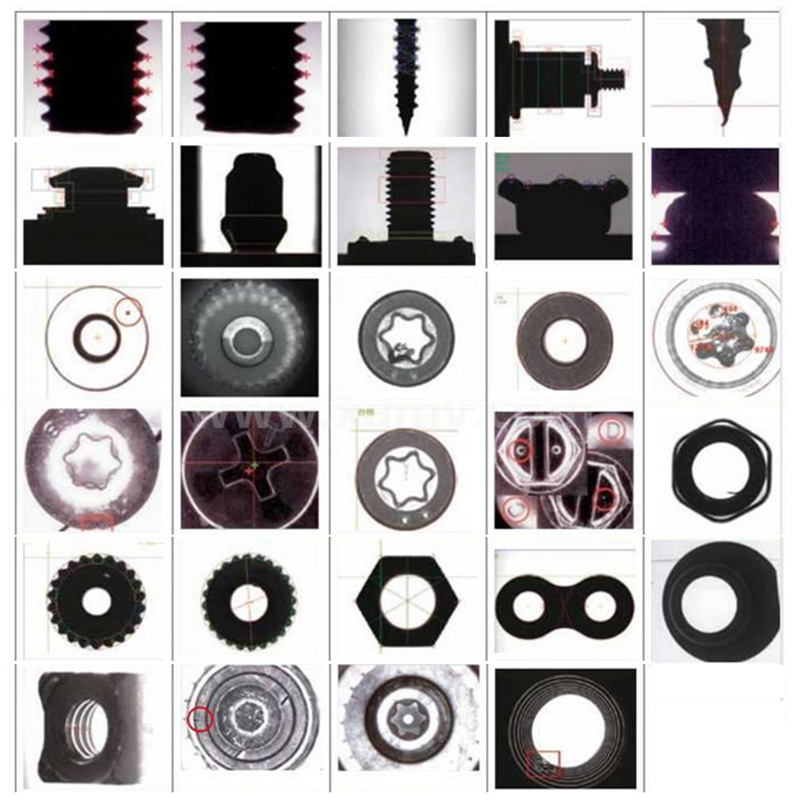

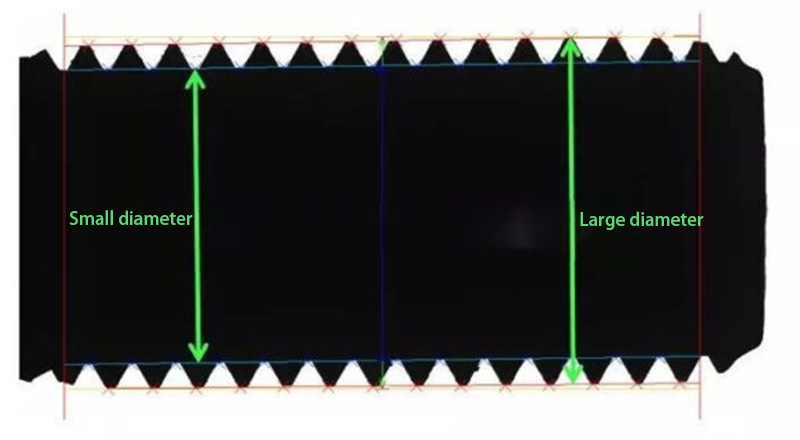

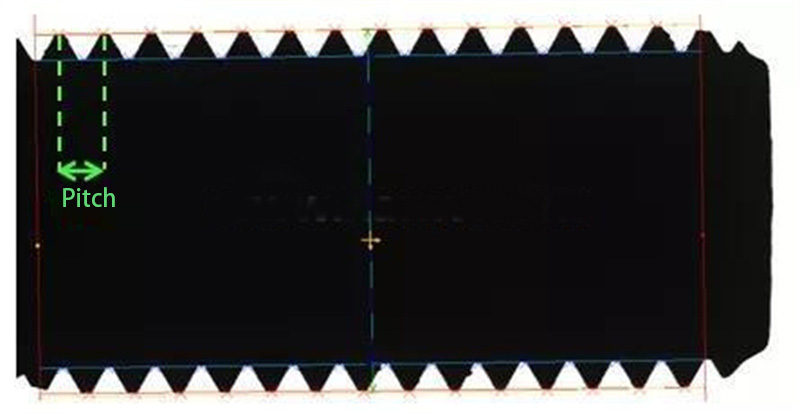

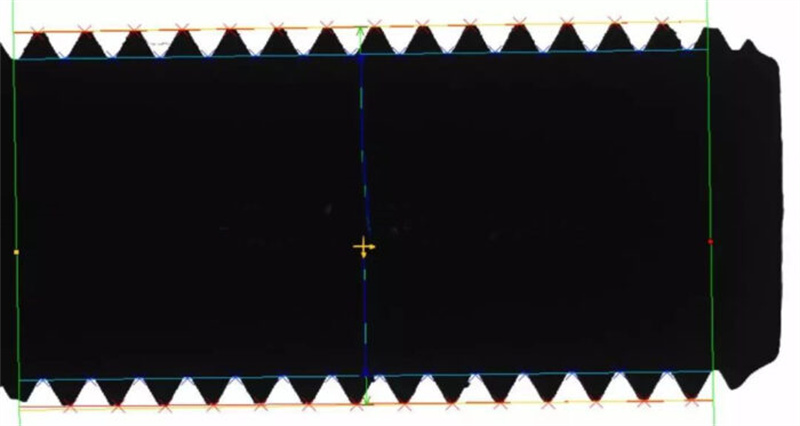

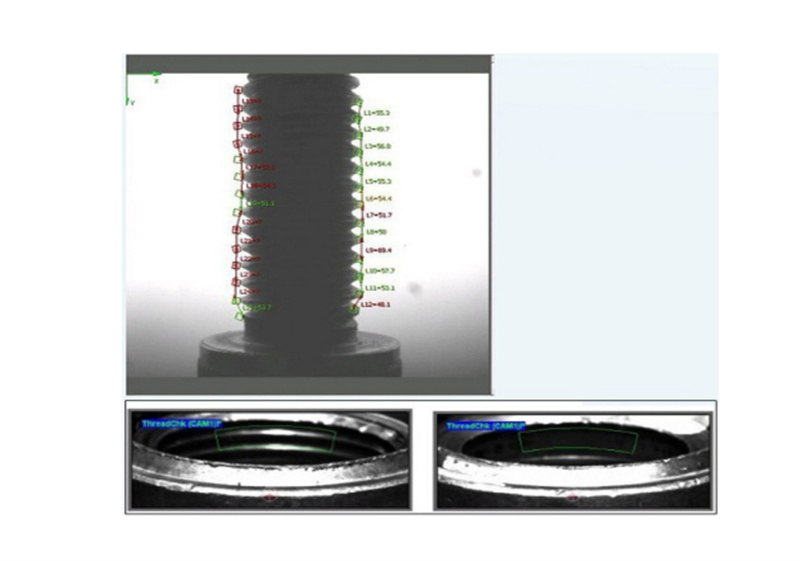

The following are some examples of thread inspection cases in hardware visual inspection and hardware accessories visual inspection dimension measurement and defect detection. With the help of the professional inspection tool of the intelligent visual system INTVision, one tool can detect the values of various thread processing parameters.

Detection content

Vision detection

1. major and minor thread diameters detection

2. Thread pitch detection

3. Thread high detection

Size measurement, defect detection

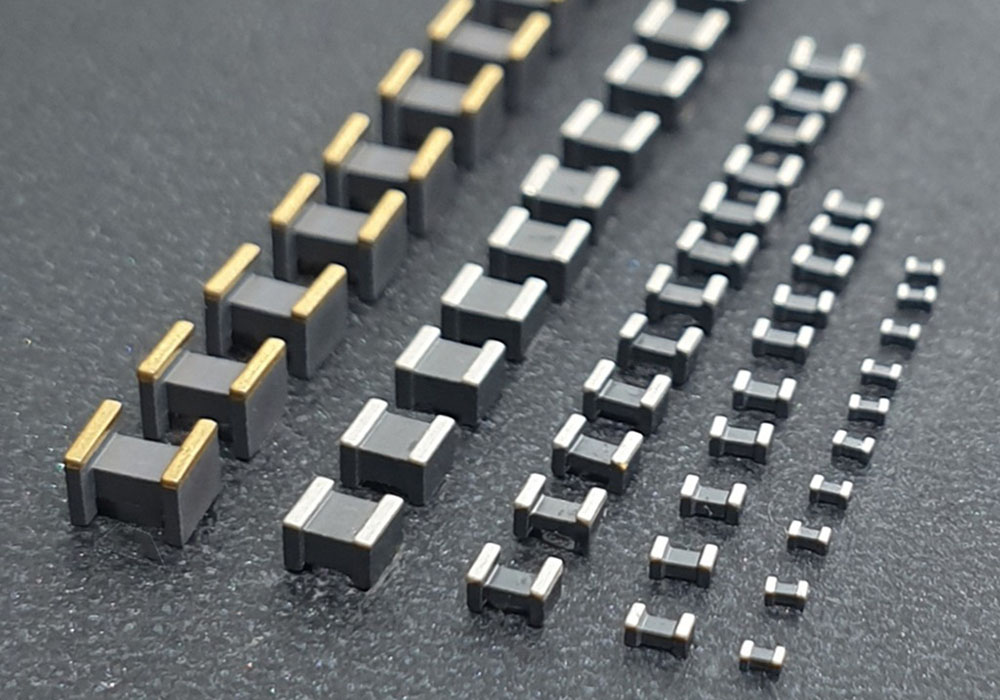

Detecting of punching product size, appearance, punching quantity, etc.

Steering booster defect detection

INTVision’s intelligent vision system can solve different types of inspections for screws, nuts, hardware accessories, mobile phone accessories, auto accessories, small screws, precision screws, gaskets, special shaped parts, stamping parts, injection molded parts, galvanized screws, precision hardware, special shaped hardware, etc. The inspection types include: cracks, burrs, head text/shape, length, diameter, presence or absence of cut tail, pinhole concentricity/roundness, presence or absence of teeth on screws and nuts, inner and outer diameters of screw threads, screw thread pitch, screw thread angle, poor thread rolling, bottom shape, tailing, bending, tail cut groove, multi-segment height/width/thickness, chamfer/included angle, number of teeth, surface characteristics, surface flaws, marks, surface defects, etc. The following image shows the various detectable defects of screws: