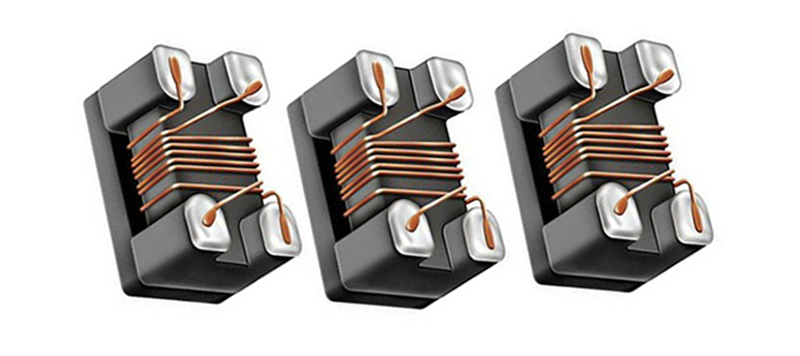

Chip inductors are a type of passive electronic component used in electronic circuits to provide inductive reactance, which is the opposition to changes in electrical current. They are a popular choice for a variety of applications due to their compact size, high inductance, and low cost.

For these small but critical electronic components, how to guarantee their quality when they come out of the factory, to avoid defects caused by the lack of functionality of electronic products?

It should be detected by machine vision.

Machine vision, which involves the use of digital imaging and computer vision techniques, has become an essential tool for quality control and inspection in the electronics manufacturing industry, including the inspection of chip inductors.

The following is an case study of chip inductor defect detection by Intsoft Technology.

Detection content and requirements:

Surface detection of products with maximum dimensions of L14mm*W14mm*H6mm.

| No. | Position | Method | Detectability or not |

| 1 | Incomplete,cracked | Positive light detection | YES |

| 2 | Scratch | Positive light detection | YES |

| 3 | defective terminal | Positive light detection | YES |

| 4 | Stain, foreign matter | Positive light detection | YES |

| 5 | Exposed copper | Positive light detection | YES |

Note: Chip inductor machine vision detection equipment, all need to be clearly visible under the image to detect.

Detection detail:

Detection efficiency: The number of detections per minute is not less than 200 pieces (depending on the product feeding speed).

Equipment composition and main body of the equipment Model: YTD-T300 standard detecting equipment Overall dimensions: 900*800*1850mm

List of components:

| No. | Component name | Model | Quantity |

| 1 | Vision detection software | Intsoft | 1 set |

| 2 | industrial computer | Intsoft customized | 1 set |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set |

| 4 | Industrial camera | Barsler industrial camera | 6 set |

| 5 | Camera adjustment module | Intsoft customized | 6 set |

| 6 | Industrial Lens | FA High Definition Optical Industrial Lens | 6 set |

| 7 | Light source | Customized optical adaptive light source | 6 set |

| 8 | Inspection Platform | Professional Optical Glass Carrier | 1 set |

| 9 | Servo Motor | Panasonic | 1 set |

| 10 | Control System | Intsoft customized | 1 set |

| 11 | PLC motion collaboration | Panasonic | 1 set |

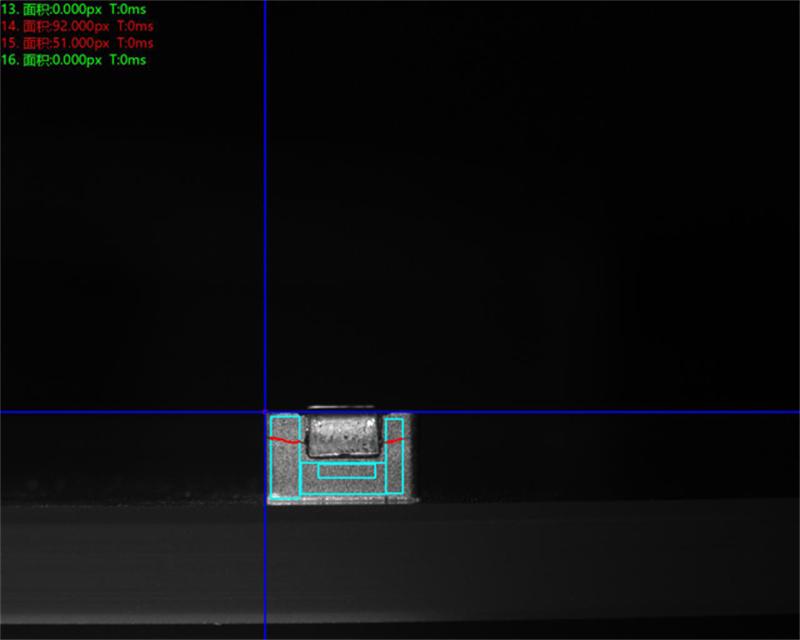

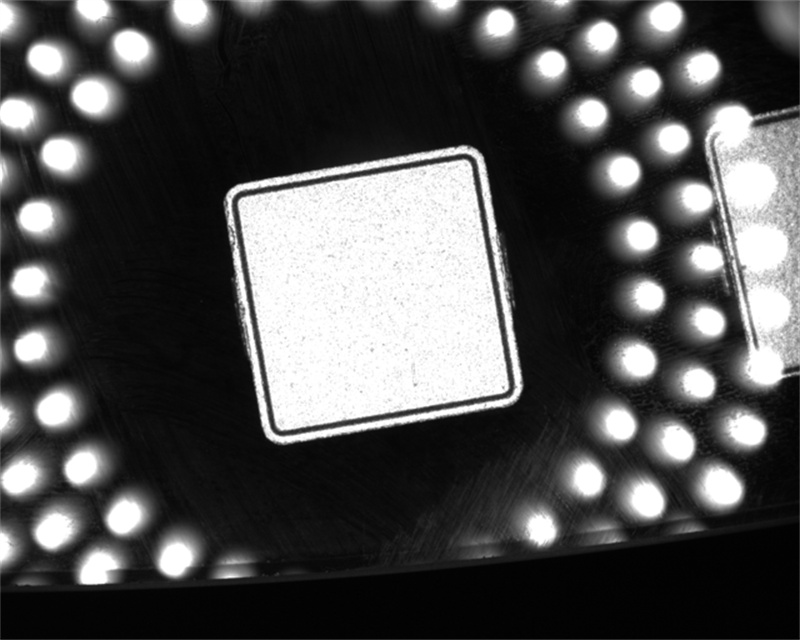

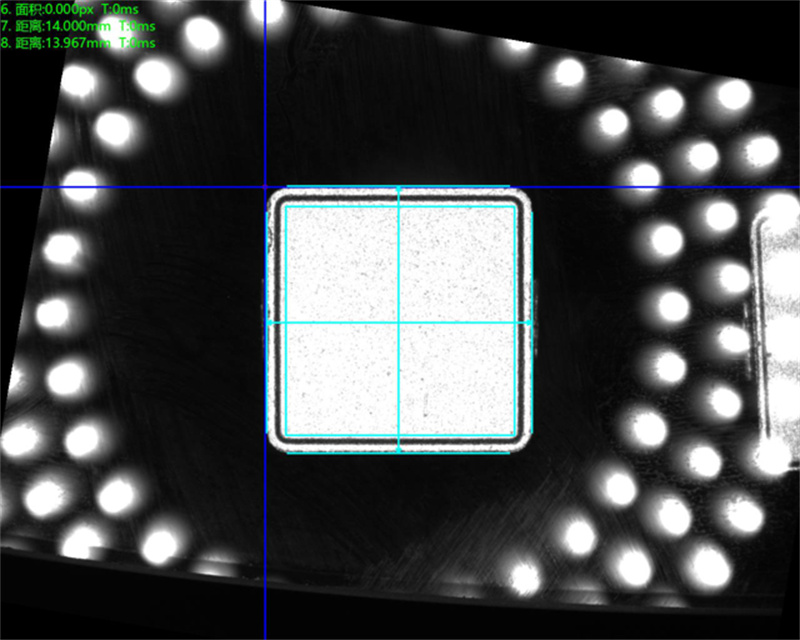

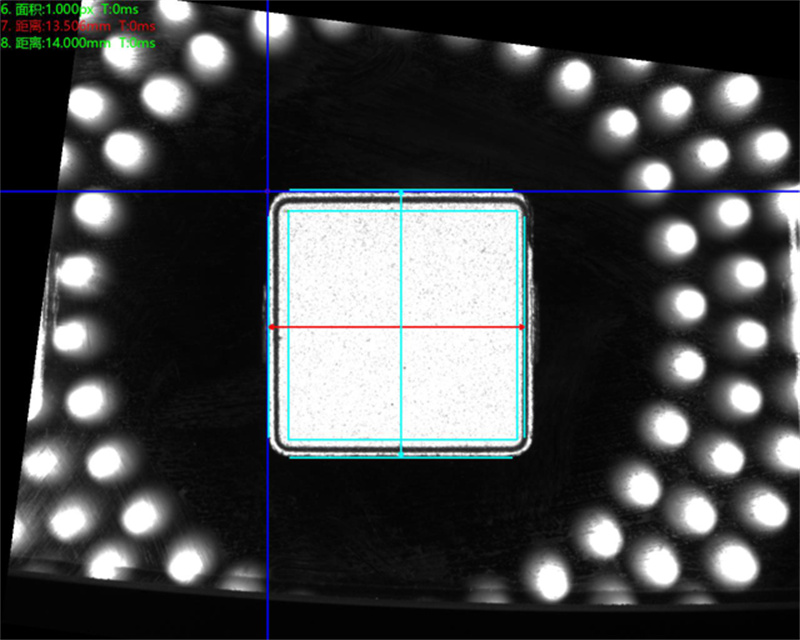

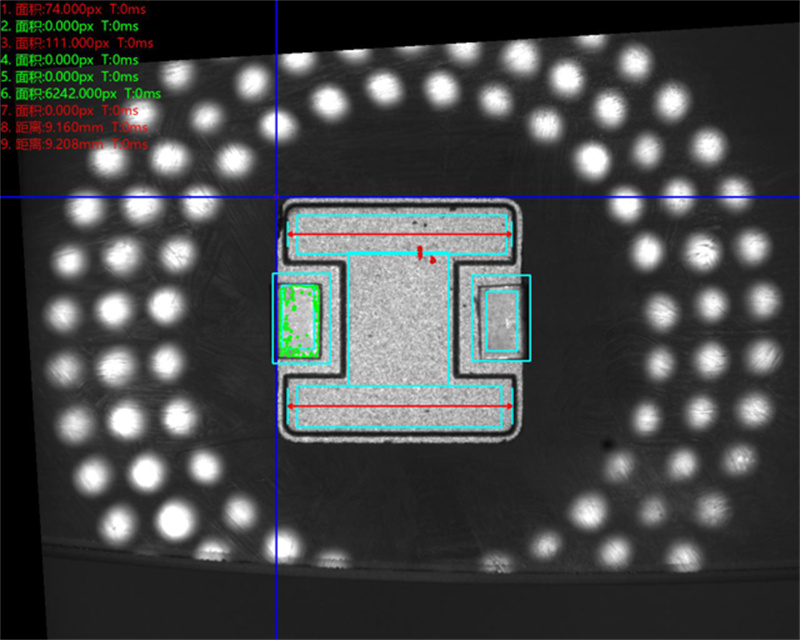

Detected sample image:

Bottom detection

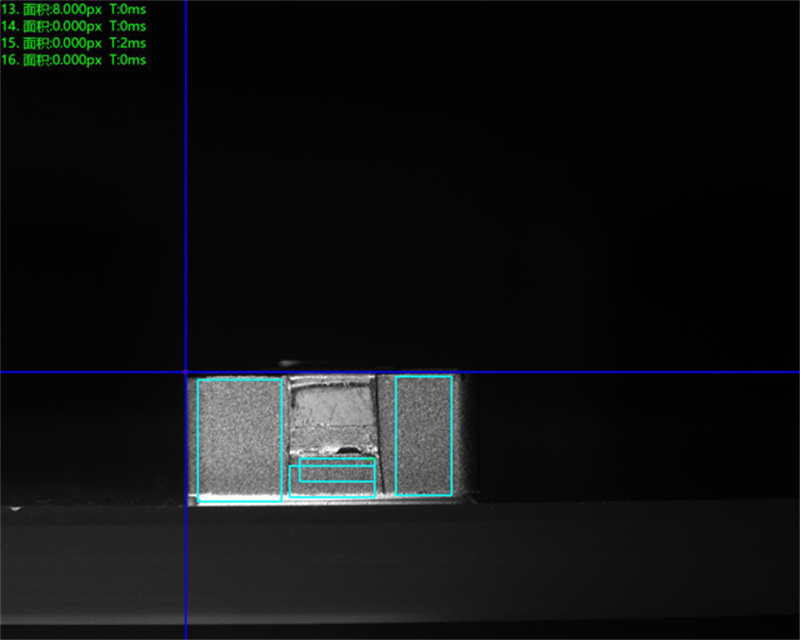

Bottom detection original image:

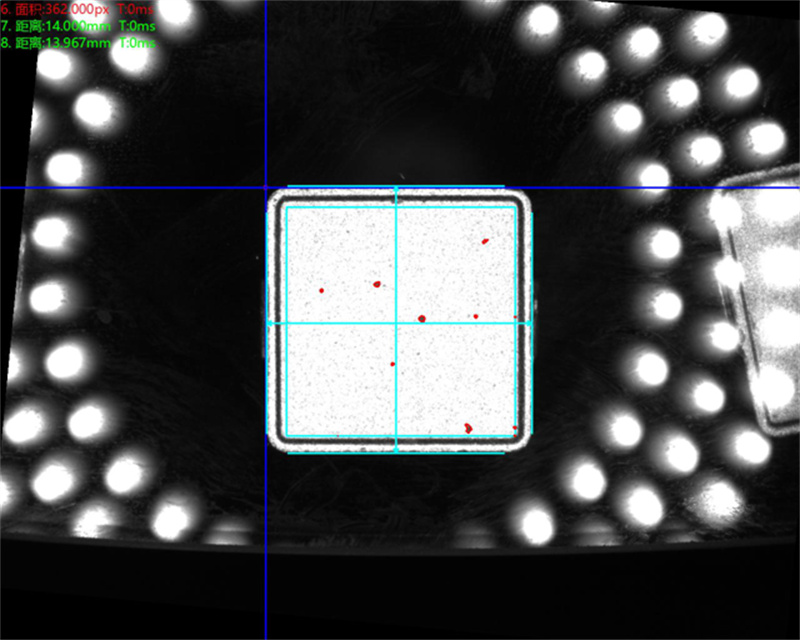

Bottom Positive Light detection good product analysis image: OK

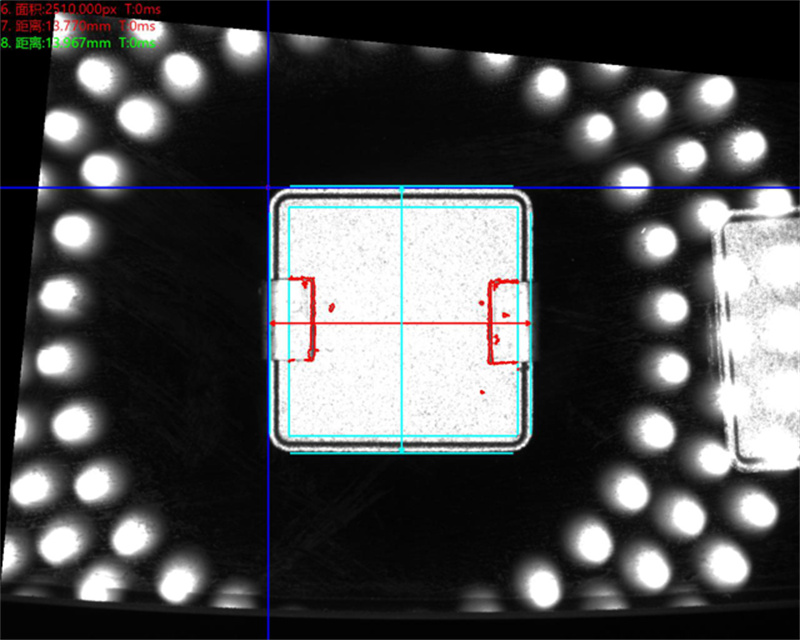

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Damage

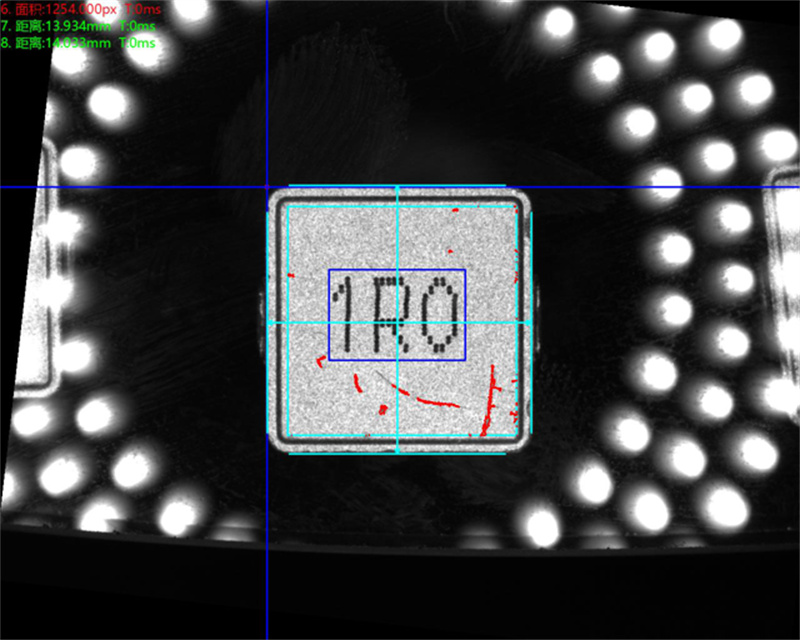

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Terminal reversal

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Stain

Bottom Positive Light detection defective product analysis image: NG Cause of defect: Cracked

Top detection

Top positive light detection good product analysis image: OK

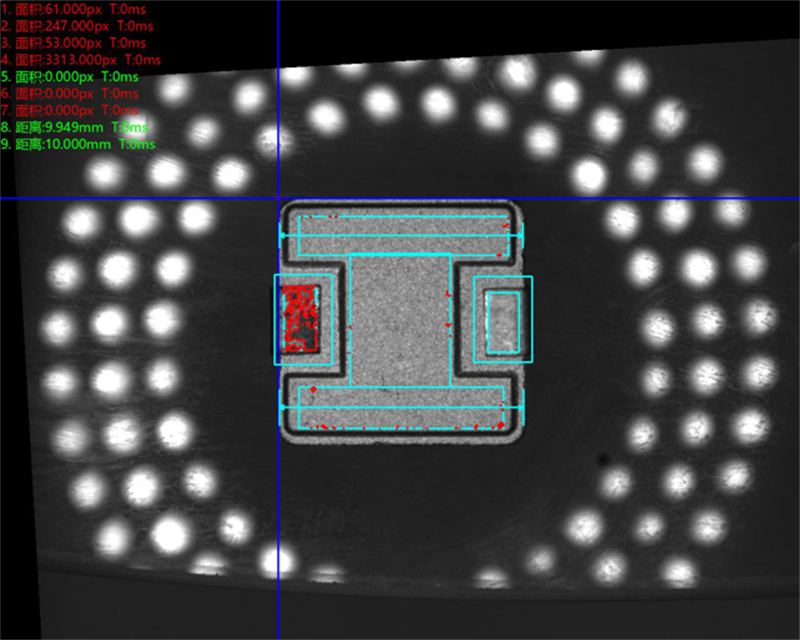

Top positive light detection defective product analysis image: NG Cause of defect: Terminal blackening

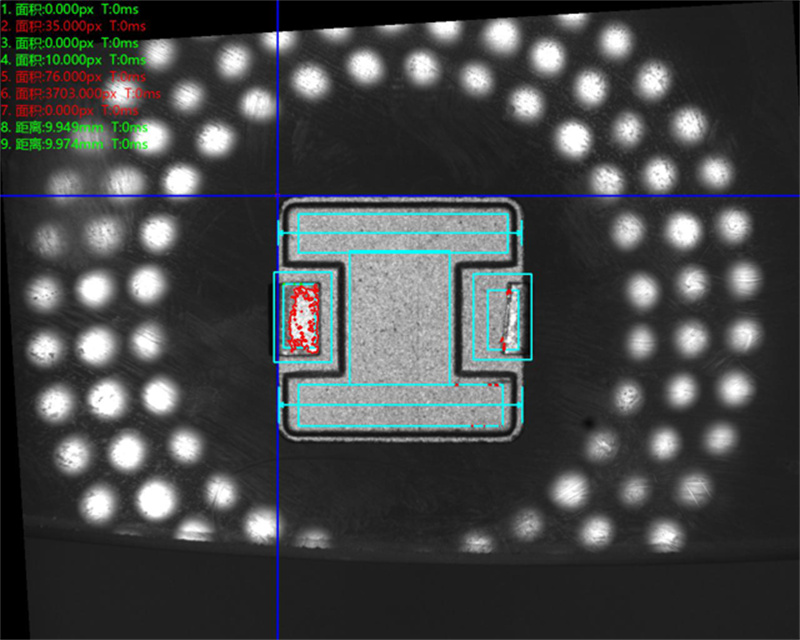

Top positive light detection defective product analysis image: NG Cause of defect: Uneven terminal

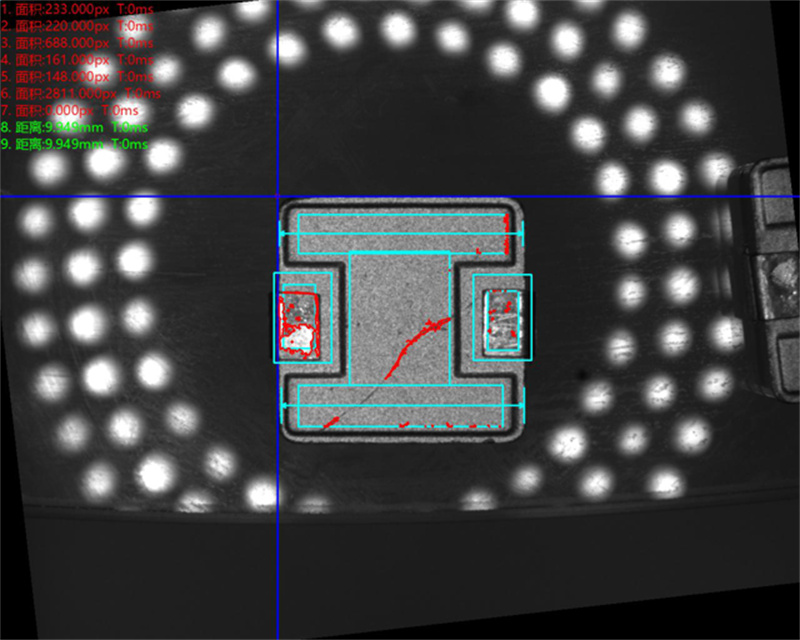

Top positive light detection defective product analysis image: NG Cause of defect: Crack

Top positive light detection defective product analysis image: NG Cause of defect: Terminal reversal

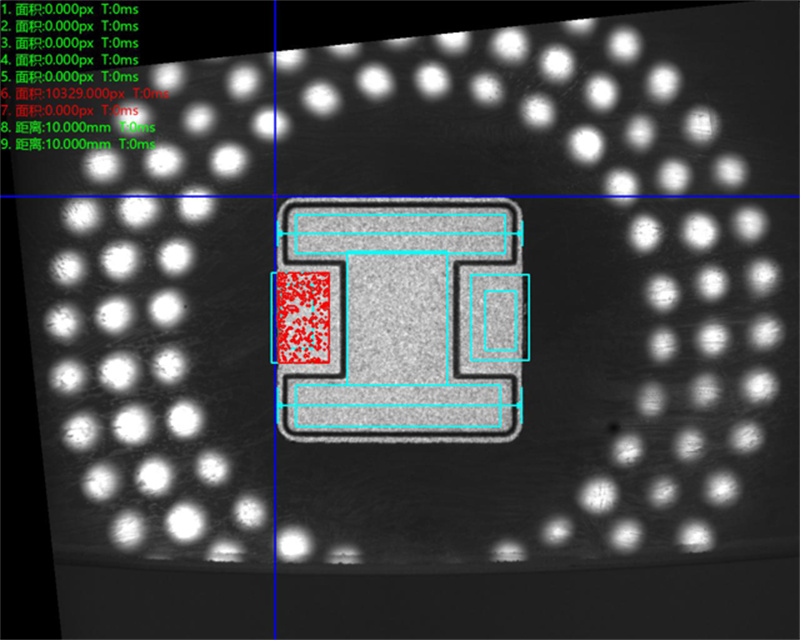

Top positive light detection defective product analysis image: NG Cause of defect: Terminal edge broken

Top positive light detection defective product analysis image: NG Cause of defect: Incomplete

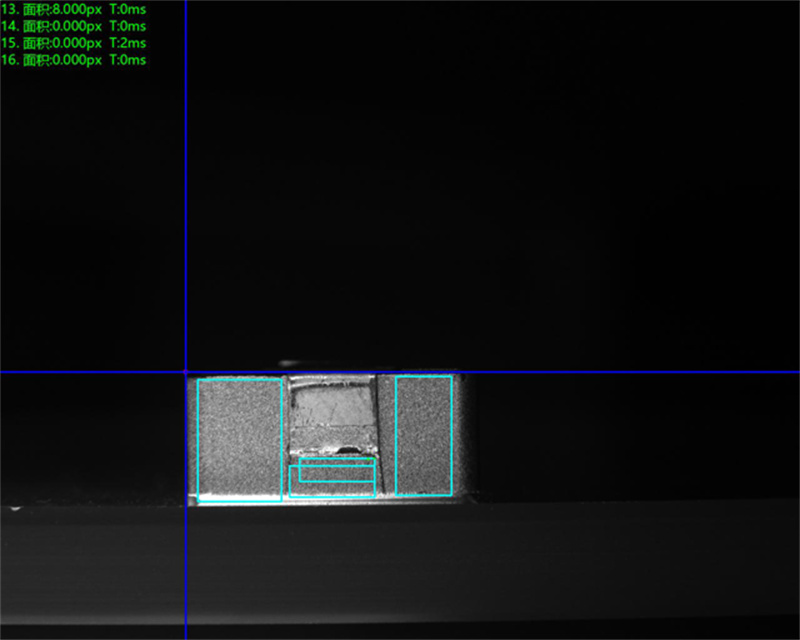

Front detection

Front positive light detection good product analysis image: OK

Front positive light detection defective product analysis image: NG Cause of defect: Uneven terminal

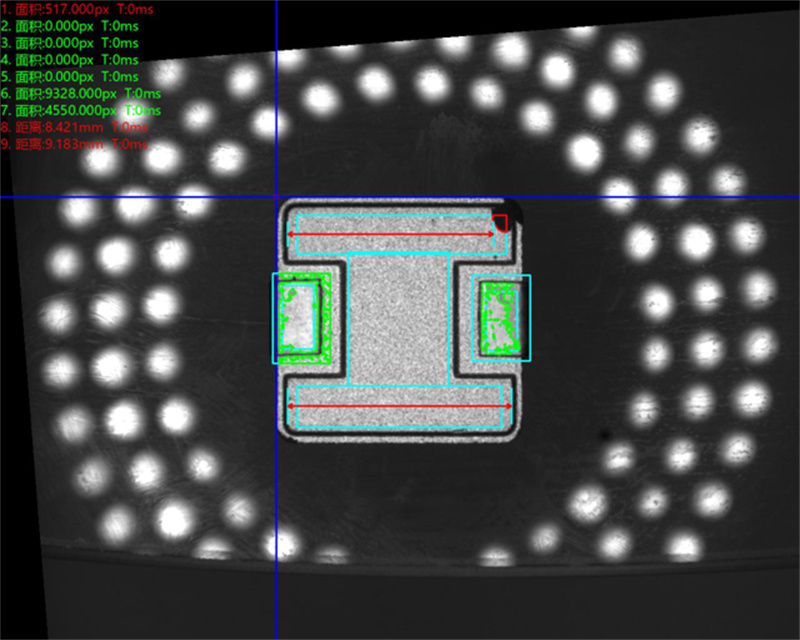

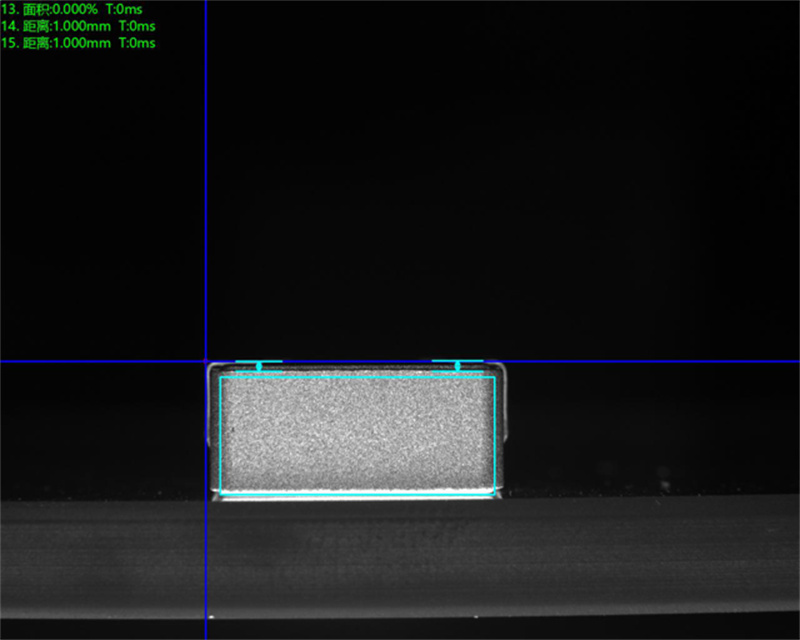

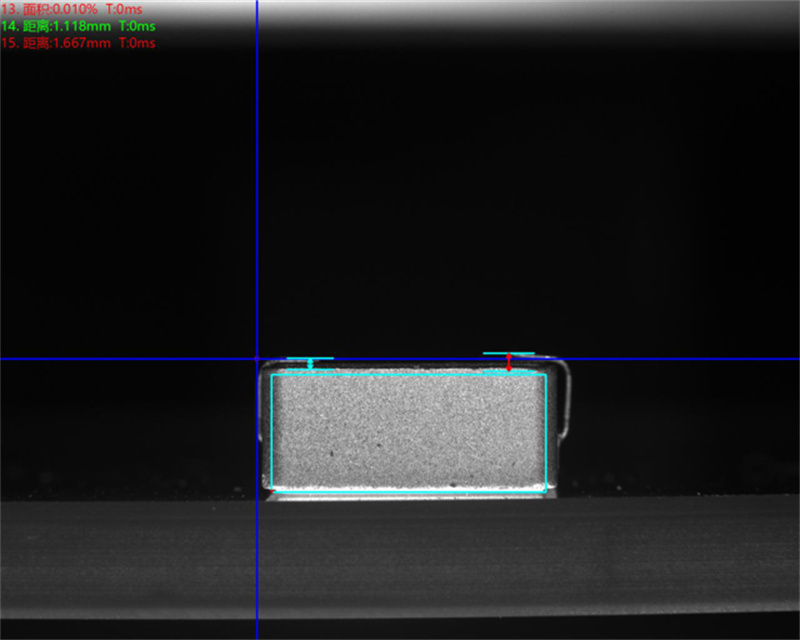

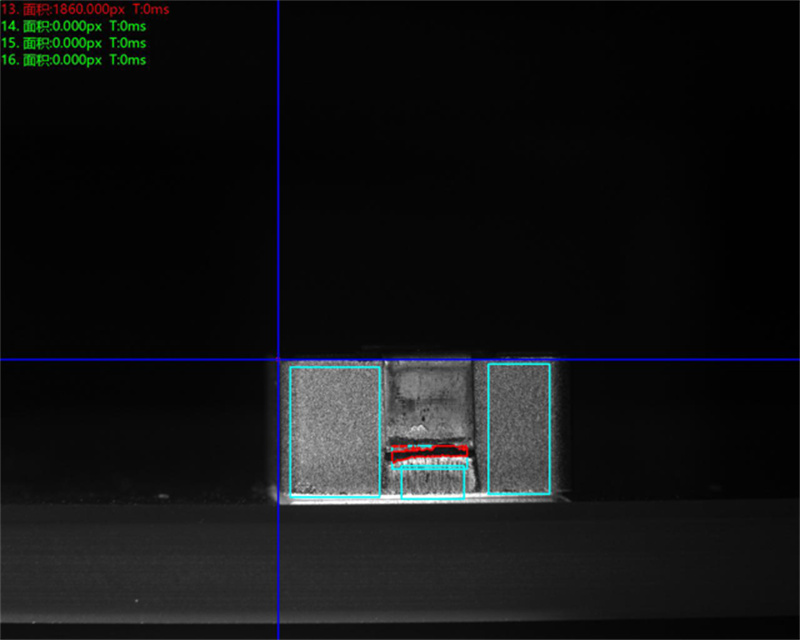

Side detection

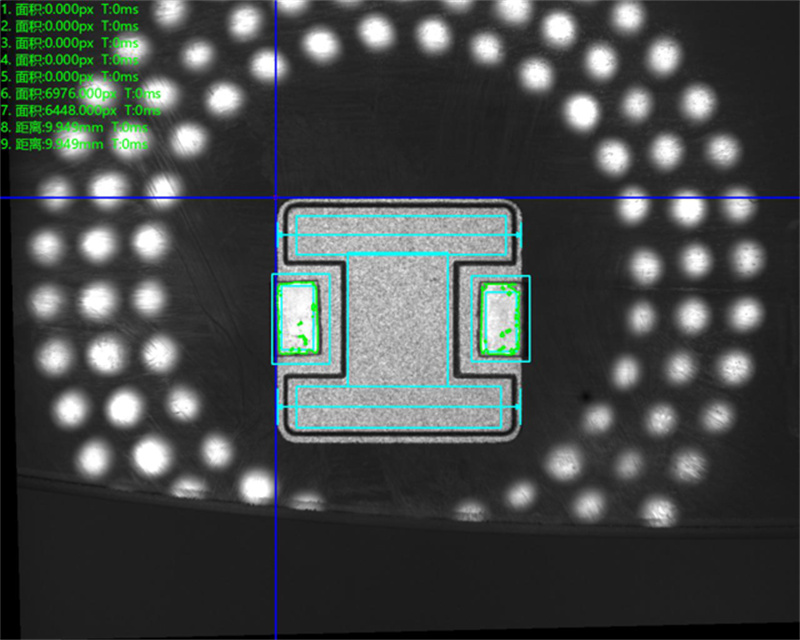

Side positive light detection good product analysis image: OK

Side positive light detection defective product analysis image: NG Cause of defect: Exposed copper

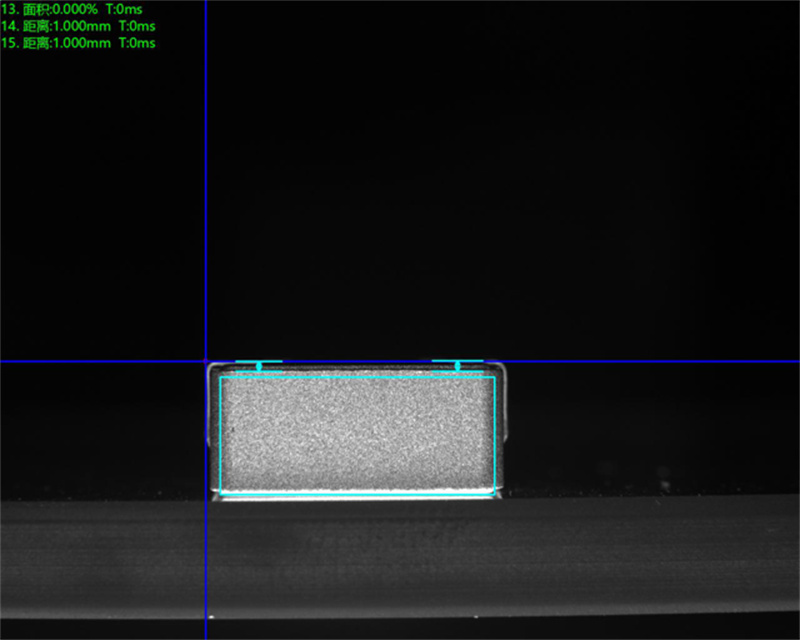

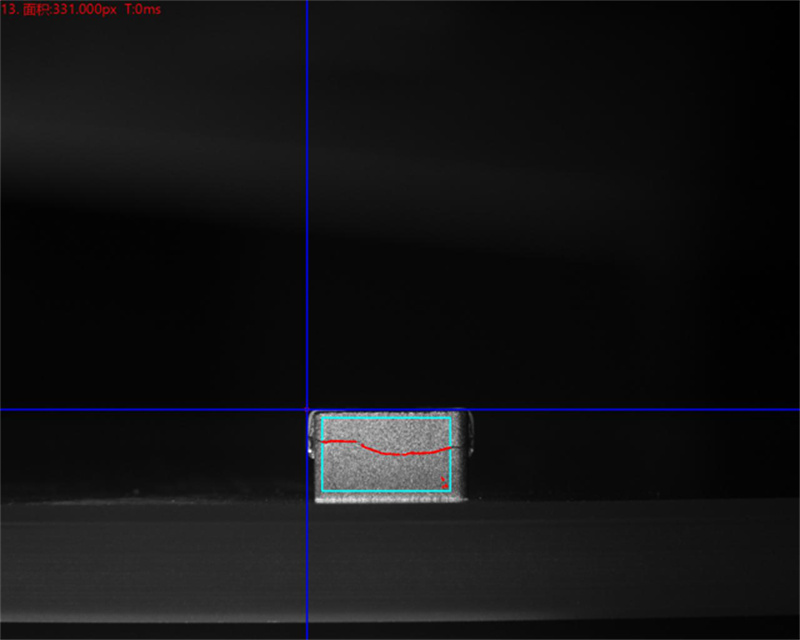

Back detection

Back positive light detection good product analysis image: OK

Back positive light detection defective product analysis image: NG Cause of defect: Crack

Back positive light detection good product analysis image: OK

Back positive light detection defective product analysis image: NG Cause of defect: Terminal blackening