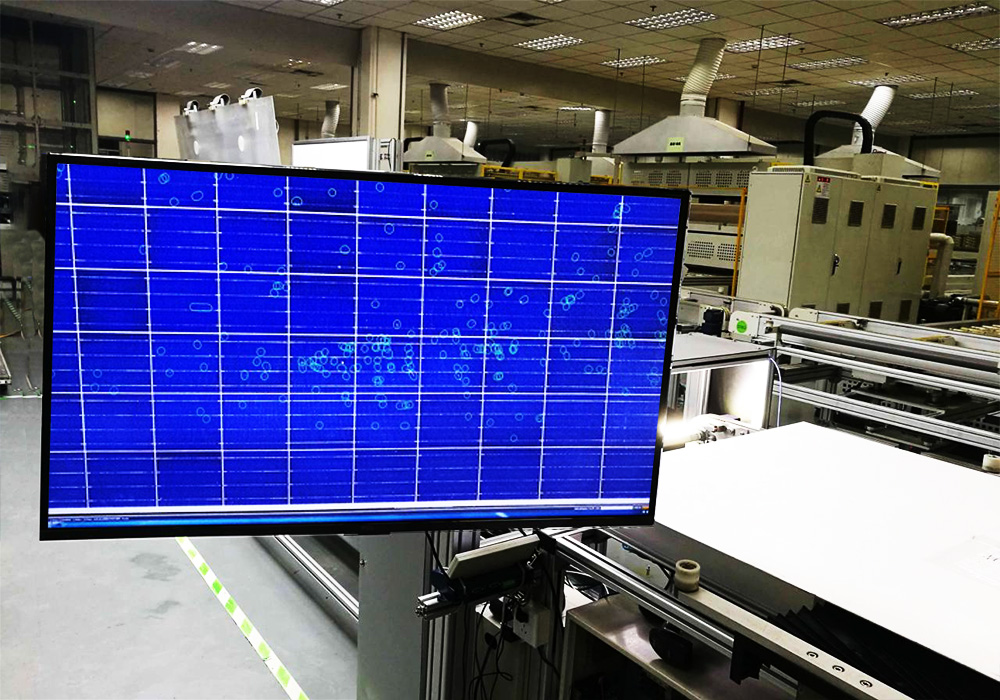

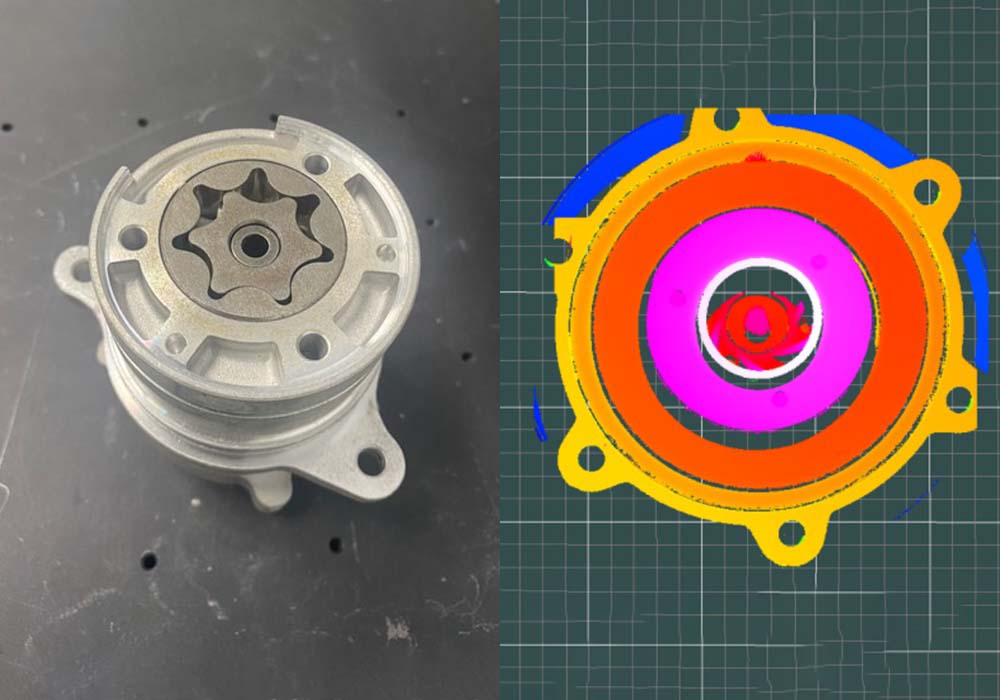

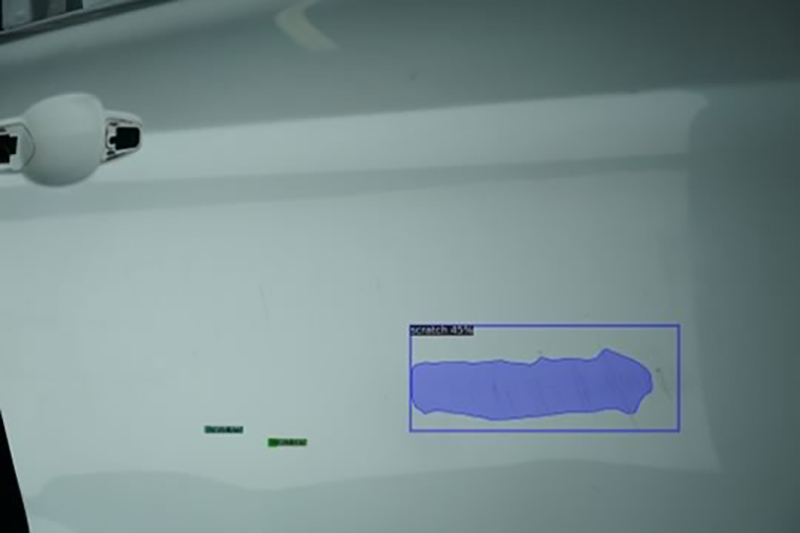

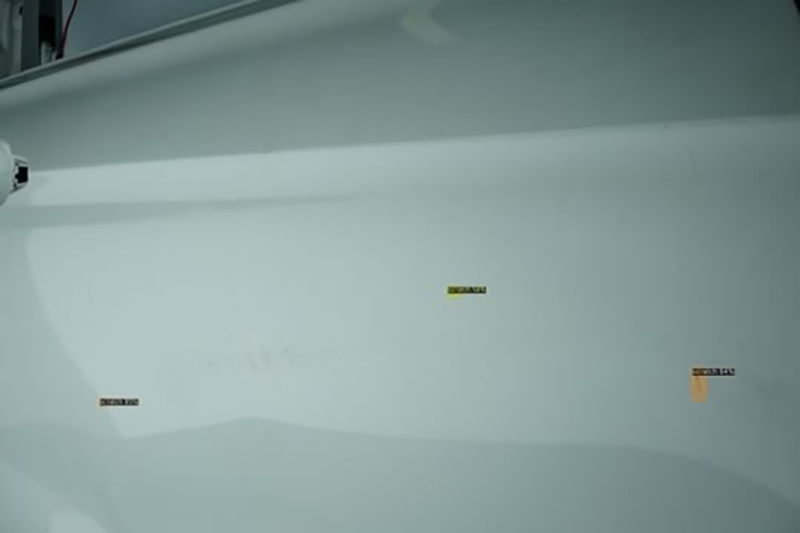

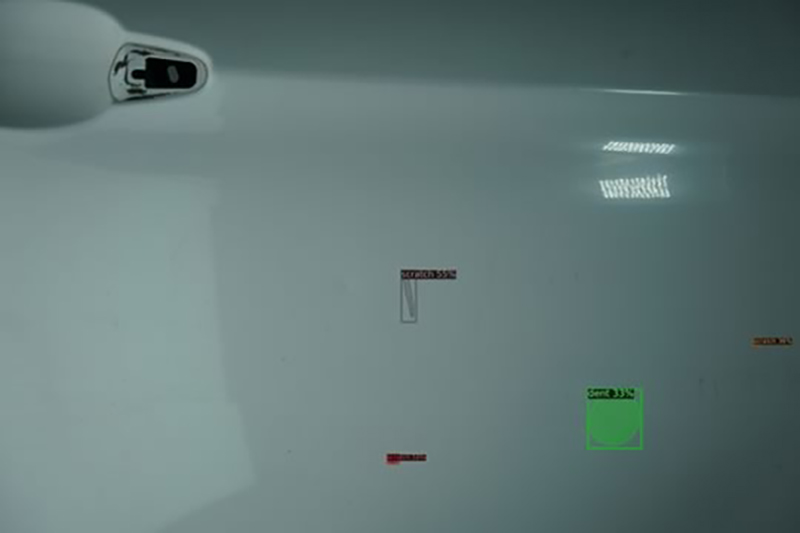

AI self-learning of various defects automatically identifies damage and marks relevant locations. The highest accuracy can reach 2mm.

Automatically generates inspection reports within 30 seconds. Processes massive amounts of information 24/7.

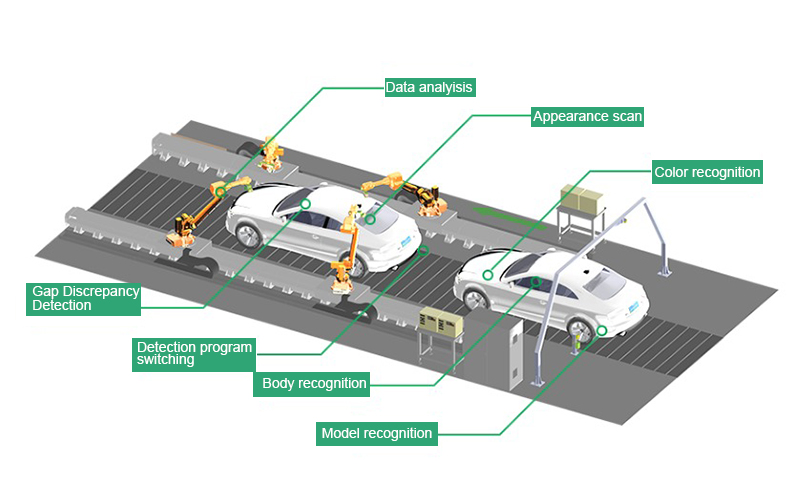

Automative appearance AI visual inspection equipment functions:

- Automatic recognition for automative model and color.

- Automatically adjust lighting according to automative color and speed with non-stop inspection mode.

- 4K pixel level photo shooting, processing, and display.

- AI automatically recognizes automative damage.

- Automatic defect marking: type, location, and size.

- Inspection reports issued in the 30 seconds.

- Intelligent algorithms, continuous self-iteration.

- Application scenarios: OEM/ports/car dealers

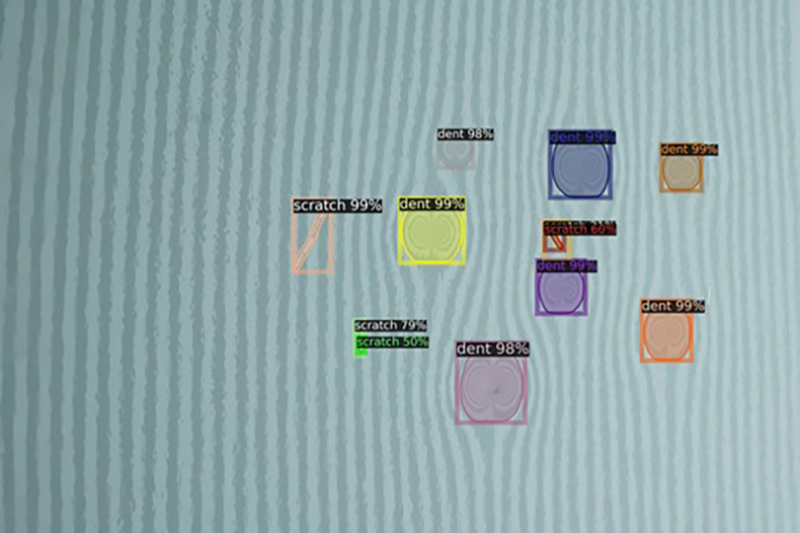

Automatically identifies and marks damage type, location and size

Case 1:

Total damage: 13

Dents: 7

Size: [20, 56] MM Area: 1120 MM2

Size: [23, 61] MM Area: 1403 MM2

Scratches: 6

Size: [5, 64] MM Area: 320 MM2

Size: [3, 28] MM Area: 84 MM2

Case 2:

Total damage: 3

Dents: 3

Size: [26, 81] MM Area: 2106 MM2

Size: [24, 76] MM Area: 1824 MM2

Size: [23, 73] MM Area: 1679 MM2

Scratches: 0

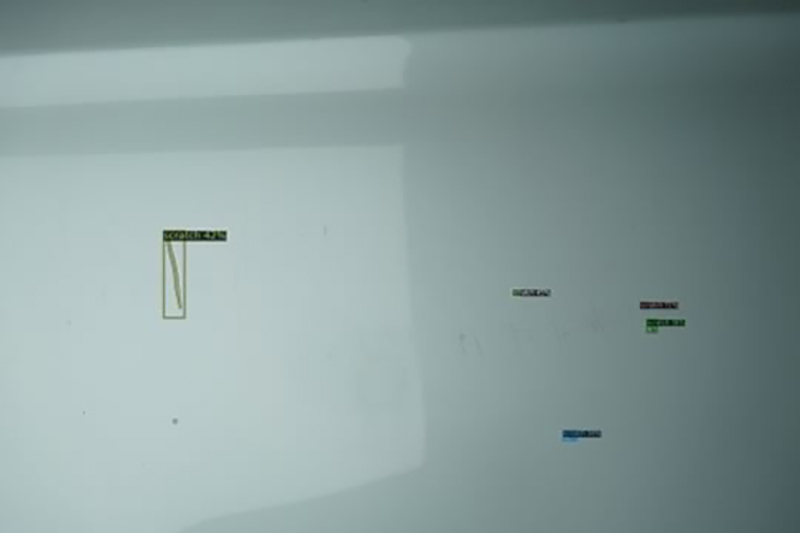

Case 3:

Total damage: 5

Dents: 0

Scratches: 5

Size: [2, 13] MM Area: 26 MM2

Size: [2, 13] MM Area: 26 MM2

Case 4:

Total damage: 3

Dents: 0

Scratches: 3

Size: [4, 14] MM Area: 56 MM2

Size: [2, 9] MM Area: 18 MM2

Size: [64, 431] MM Area: 27584 MM2

Case 5:

Total damage: 3

Dents: 0

Scratches: 3

Size: [2, 12] MM Area: 24 MM2

Size: [7, 48] MM Area: 336 MM2

Size: [4, 23] MM Area: 92 MM2

Case 6:

Total damage: 4

Dents: 1

Size: [39, 118] MM Area: 4602 MM2

Scratches: 3

Size: [5, 19] MM Area: 95 MM2

Size: [5, 79] MM Area: 395 MM2

Size: [3, 14] MM Area: 42 MM2

Solution

For OEM

In the race to Industry 4.0, automotive manufacturing has achieved more than 90% AI production. However, in the field of vehicle quality monitoring and inspection, there are still problems such as a large amount of manpower input and outdated equipment, resulting in low efficiency, failure to reduce error rates, and high costs.

The AI-based 360° automotive full-body surface defect inspection solution will assist OEMs in solving these problems by reducing operating costs, upgrading quality control systems, and improving work efficiency.

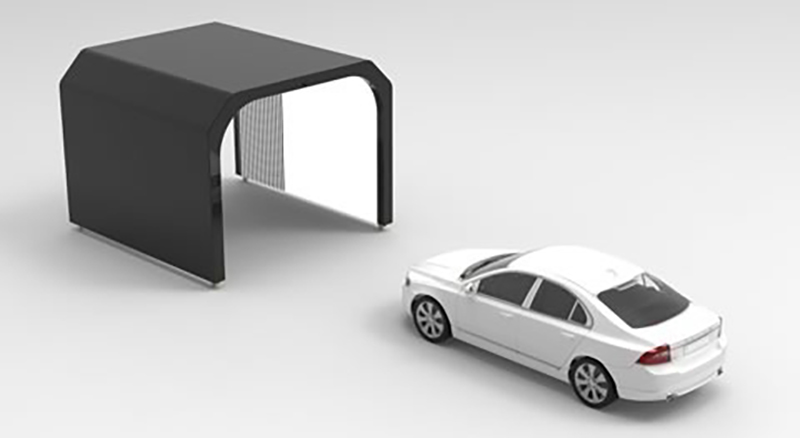

360° scanner, adaptive transmission speed

Designed for OEM

High speed and high resolution automatic scanning without stopping the assembly line

For vehicle logistics distribution centers and ports

With the development of the market and the innovation of technology, the vehicle logistics industry is also undergoing earth-shaking changes. Customer expectations are constantly increasing.

Today, vehicle logistics distribution centers are under higher requirements, not only to serve vehicles of multiple brands and models, provide value-added services in the automotive aftermarket, but also to provide more vehicle inspection services in the logistics process.

By using an AI-based 360° vehicle full-body surface defect detection solution, a large number of vehicles can be automatically inspected, digitally tracked and managed, and operating costs can be continuously reduced, bringing more business opportunities in the future.

360° automatic high-resolution scanning

High-speed scanning, instant processing of large amounts of vehicle information.

For dealers

Vehicle inspections by dealers have always been done manually. Manual inspections are relatively slow, costly, and prone to subjective judgments.

The accumulation of problems caused by manual differential diagnosis is prone to disputes and customer complaints, increasing operating costs.

AI-based 360° full-body surface defect detection for automobiles will bring about changes. Fast and efficient inspection services will provide customers with a better experience. Objective inspections by machines will achieve zero disputes and zero complaints from customers, helping companies develop healthily and rapidly.