With the progress of science and technology, people’s living standards continue to improve, in recent years, the rapid development of the smartphone industry, the production of smart phones continue to grow, at the same time, the competition between different brands of cell phones is also increasingly fierce, in the process of product processing cell phone appearance will inevitably occur some defects, in order to enhance the competitiveness of enterprises, to obtain more benefits, the enterprise is also more and more focus on the surface quality of the cell phone shell.

The surface of cell phone cases will have scratches, bumps, pits and other defects. The traditional method of detecting surface defects is manual inspection, but the manual inspection method is subject to subjective factors of human interference is relatively large, and manual inspection is inefficient and costly, which greatly restricts the enhancement of product quality.

Machine vision is a new research direction developed on the basis of computer, electronic engineering and other disciplines.

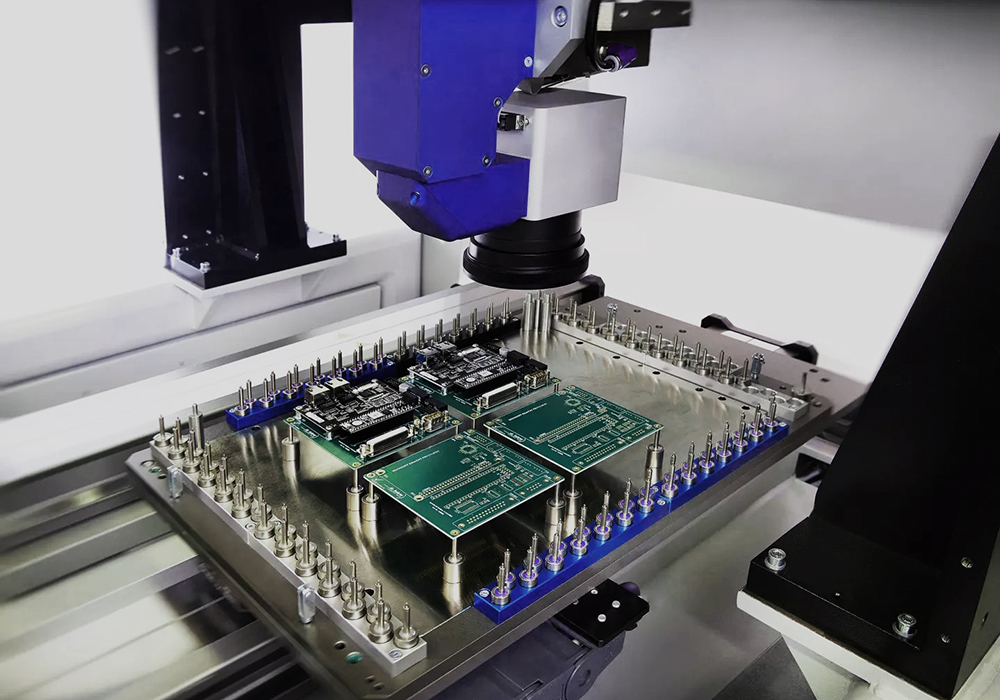

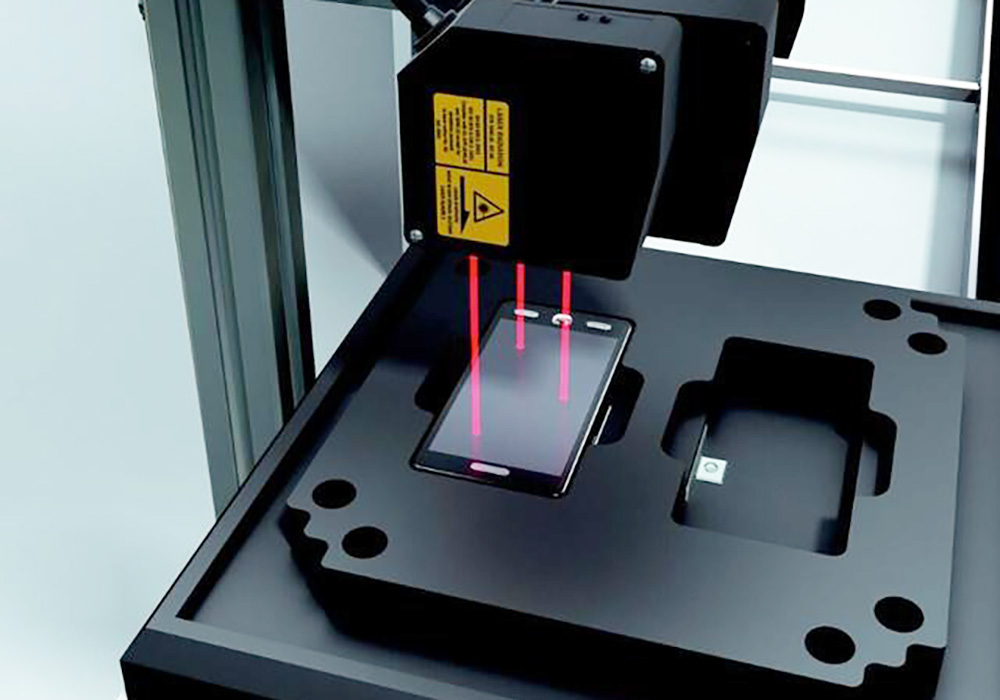

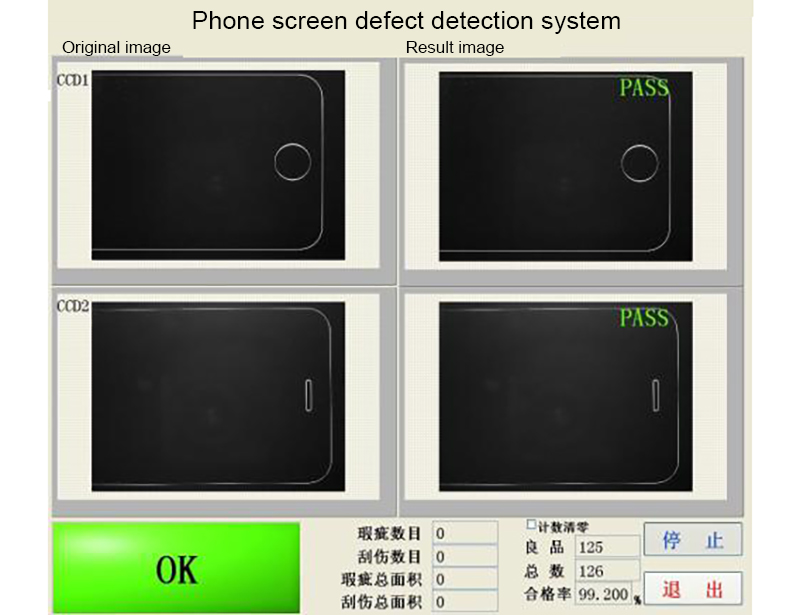

A typical machine vision inspection system mainly includes inspection object, computer, light source and camera, etc., as shown in the following figure.

The machine vision inspection system first needs to acquire images of the target by the camera in a certain light mode, and then the computer will detect the images and display the detection results.

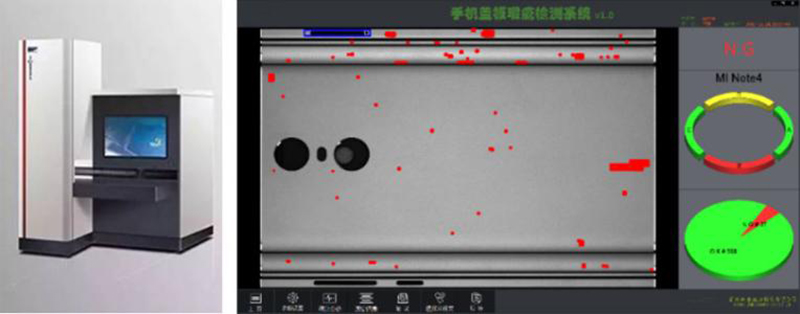

The defects to be detected are on the side of the appearance of the cell phone, which can be classified into high gloss surface and matte surface according to light reflectivity, and the high gloss surface is flat, while the matte surface has both flat and curved surfaces.

The defects on the surface of cell phone cases are of various types, such as scratches, edge bumps, pits, knife lines, etc. Intsoft analyzed the surface of the cell phone to be inspected and concluded that more than 90% of the defects on the surface of the cell phone to be inspected are scratches and hole edge bumps. Therefore, the Intsoft Intelligent Inspection System team conducted an in-depth study of scratch detection on high gloss and matte surfaces as well as matte surfaces, and adopted different illumination methods for the detection of defects in different surfaces to obtain a clear image that is conducive to the subsequent detection of defects.

In the modern industrial defect detection, benefits of machine vision inspection technology:

1. Good real-time performance.

2. High degree of automation.

3. Non-contact.

4. High accuracy.

5. Good reliability.