PCB board Introduction to detection

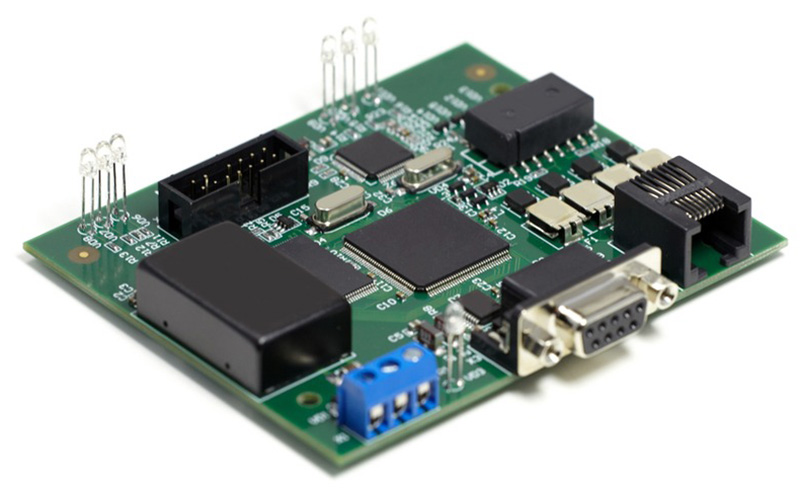

The electronics manufacturing industry has entered a period of rapid development, and as the basic engineering and core of electronic components (PCB circuit board) industry has also accelerated the pace of upgrading iteration.

Printed Circuit Board (PCB) is integrated with a variety of electronic components of the information carrier. In the field of electronics, it has a wide range of applications, and its quality directly affects the performance of the product.

In the PCB manufacturing process, the components on the PCB are commonly installed using surface mount mounting technology. With the development of electronic technology and electronic manufacturing industry, electronic products tend to be lighter, smaller and thinner.

PCB board is an important part of modern electronic equipment, due to the small size of chip components, high installation density, which requires PCB board integration to further improve.

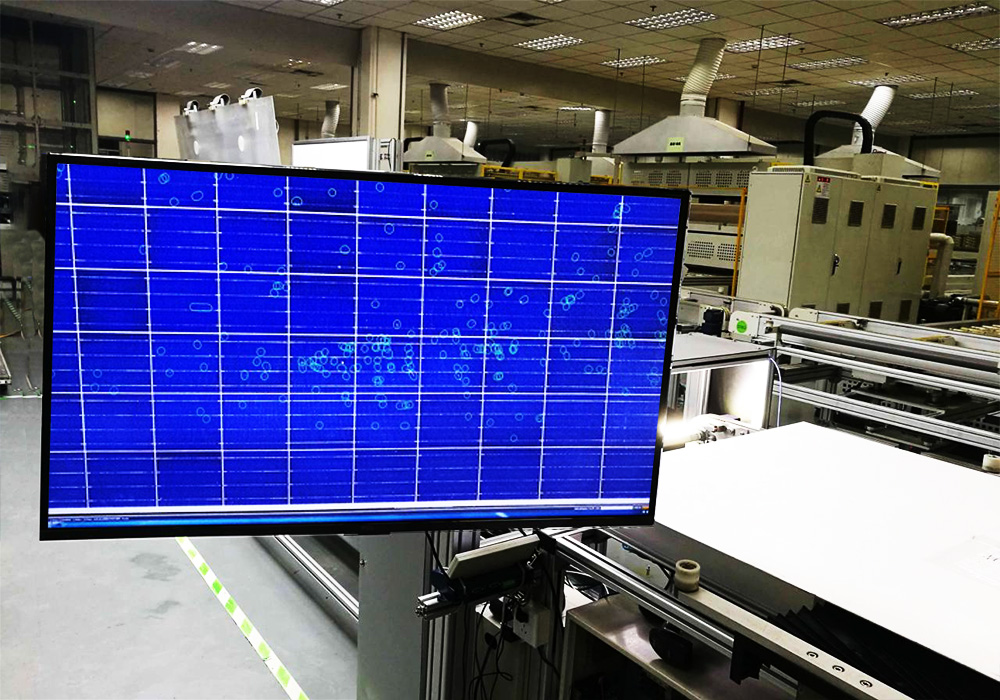

In order to ensure the performance of electronic products, PCB board defect detection technology has become a very critical technology in the electronics industry.

Circuit board defect detection includes two parts: solder joint defect detection and component detection.

Traditional detection using manual detection methods, easy to miss detection, slow detection, long detection time, high cost, has gradually been unable to meet production needs.

Therefore, it is of great practical significance to design a machine vision circuit board inspection system that efficiently and accurately carries an industrial camera to replace the human eye.

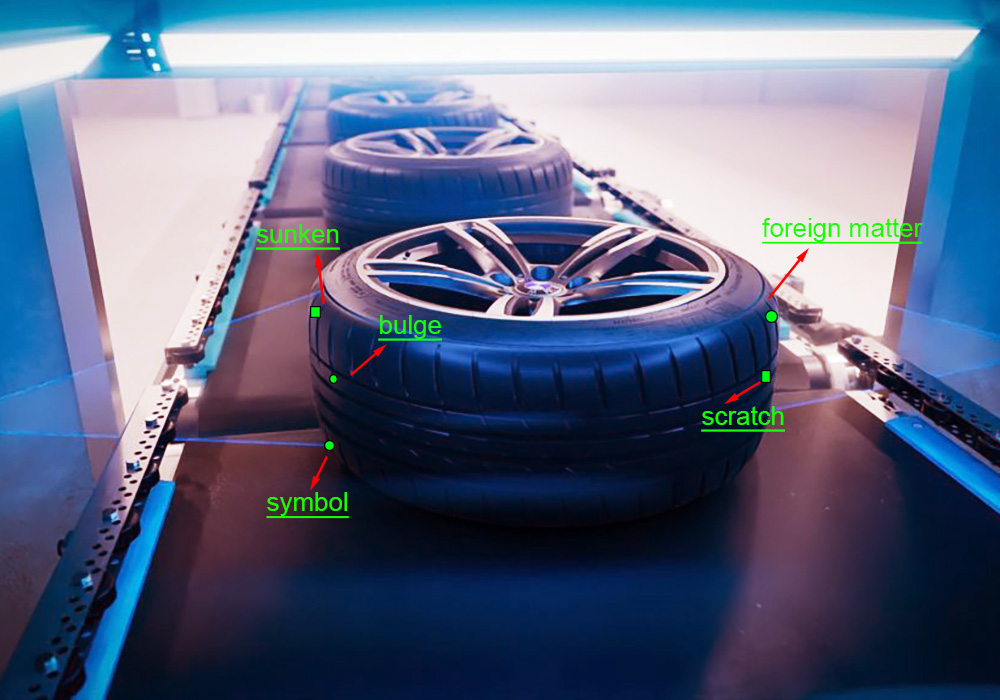

Machine vision defect detection

Machine vision inspection technology is based on image processing algorithms, digital image processing and pattern recognition methods to achieve, compared with traditional manual inspection technology, improve the efficiency and accuracy of defect detection.

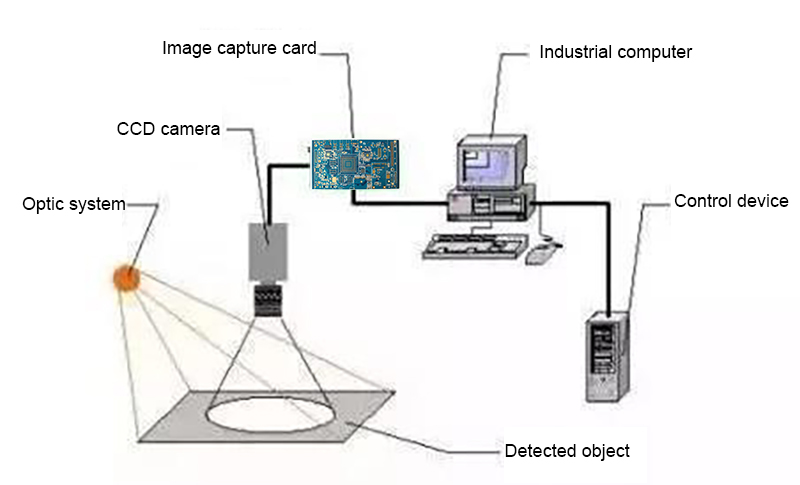

Machine vision systems generally use CCD or CMOS industrial cameras to take inspection images and convert them into digital signals, and then through computer software and hardware technology to image digital signal processing, so as to obtain the required characteristics of the various target images, and thus realize parts recognition or defect detection and other functions.

In our daily industrial production, the popularity of the application of machine vision is mainly reflected in the semiconductor and electronics industry, of which about 40-50% are concentrated in the semiconductor industry.

Specific Applications

Specific things such as PCB printed circuit: all kinds of production of printed circuit board assembly technology, equipment; single, double-sided, multi-layer circuit boards, copper-clad boards and peripheral materials and auxiliary materials; auxiliary facilities, as well as consumables, inks, potions pharmaceuticals, accessories, electronic packaging technology and equipment, screen printing equipment and screen peripheral materials , etc.