People who have done machine vision inspection systems know that traditional machine vision has many difficulties in defection, some minor scratches, blemishes, defects, and low contrast images. With traditional machine vision , it’s hard to deal with. These are industrial inspection has always existed, it is difficult to solve the big problem.

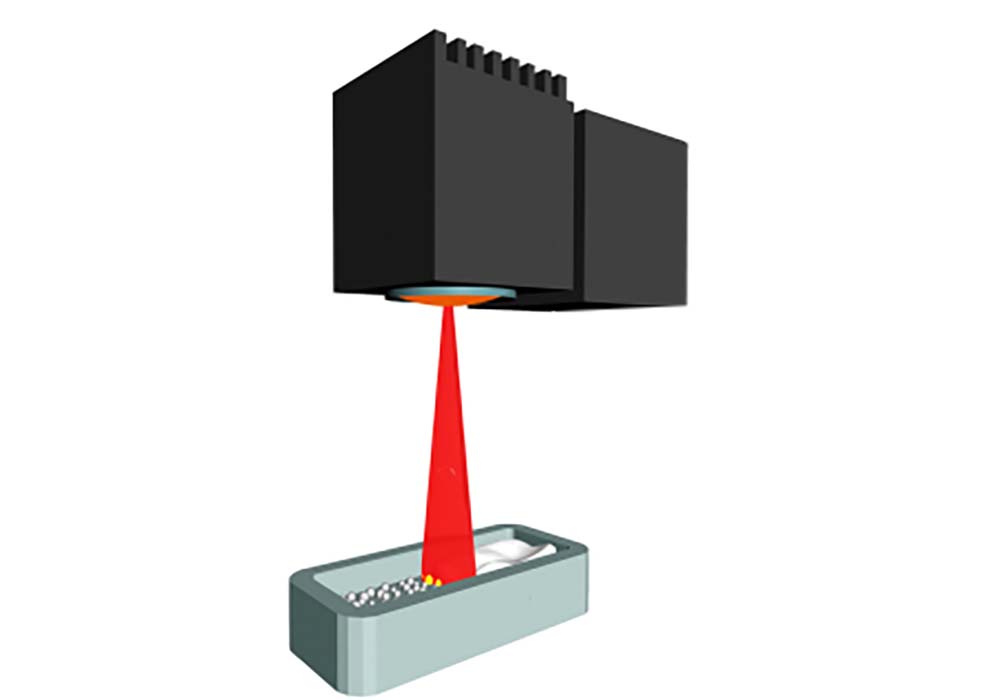

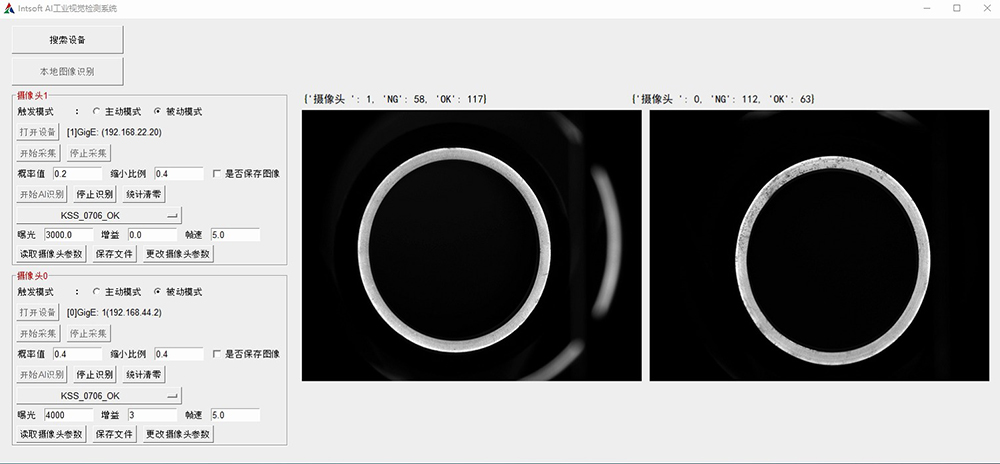

In the face of these difficulties, Intsoft Technology has been working hard to overcome. At present, we have developed our own intelligent deep learning vision inspection system. In image processing, the smallest and the slightest defects have nothing to hide.

Customize various detection functions according to customer needs.

Customer on-site use cases:

Deep learning application in industrial

Predictive Maintenance:

Using deep learning models to predict equipment failures and schedule preventive maintenance.

Analyze sensor data, vibration patterns, and maintenance logs to identify early signs of potential problems.

Improve equipment uptime and reduce unplanned downtime.

Quality Inspection and Defect Detection:

Automate visual inspection of products, materials, and components using deep learning-based computer vision.

Detect defects, anomalies, and quality issues with high accuracy and consistency.

Integrate deep learning models into industrial automation and manufacturing processes.

Process Optimization and Control:

Optimizing production parameters and control systems using deep learning models.

Predict optimal settings for variables such as temperature, pressure, flow, and energy consumption.

Enhance process efficiency, productivity, and resource utilization.

Anomaly and Fault Detection:

Identify unusual patterns in industrial sensor data, process parameters, and operational logs.

Detect early signs of equipment failures, process deviations, and safety incidents.

Enabling proactive maintenance and risk mitigation strategies.

Inventory and Supply Chain Management:

Forecasting demand, inventory levels, and supply chain dynamics using deep learning models.

Improve inventory optimization, logistics planning, and distribution efficiency.

Enhance supply chain visibility and resilience.

Robotics and Automation:

Enabling advanced perception and control capabilities for industrial robots and autonomous systems.

Improving object detection, recognition, and manipulation through deep learning-based computer vision.

Enhance the flexibility and adaptability of industrial automation.

Energy Management and Optimization:

Optimizing energy consumption and distribution in industrial facilities.

Predicting energy demand, identifying energy-saving opportunities, and managing renewable energy resources.

Improving overall energy efficiency and sustainability.