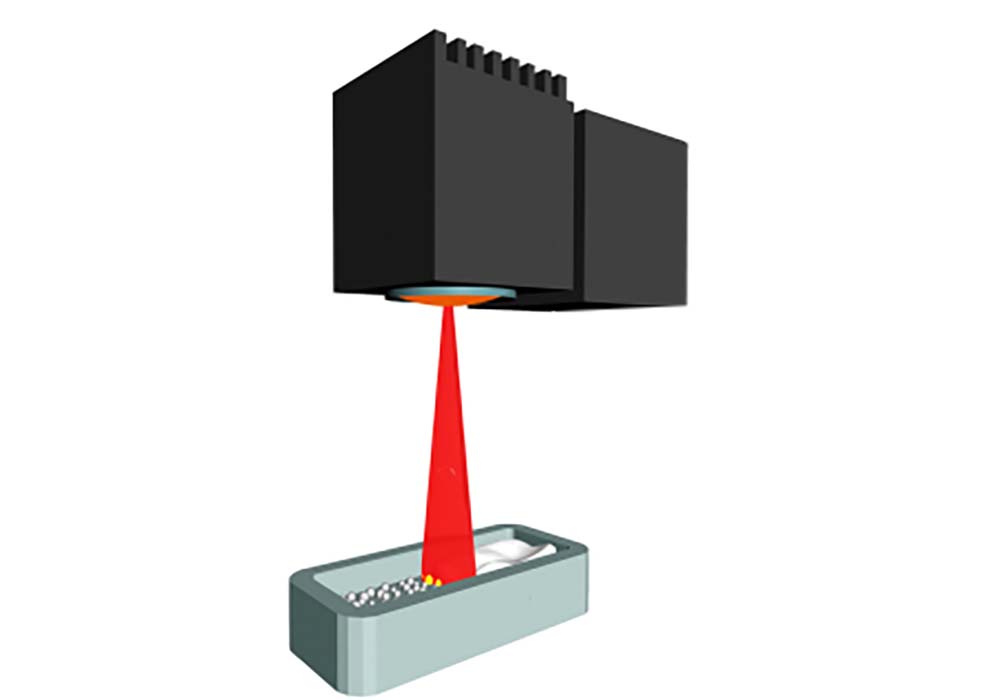

Laser marking, cutting, welding, micro-machining, etc., are currently using machine vision technology. Machine vision can allow the laser to automatically locate and align, and then proceed to the next step, making the machine more intelligent.

The laser processing industry is introducing machine vision, using industrial cameras instead of human eyes to detect processed objects. The resolution and frame rate can be selected according to the processing requirements, eliminating the harm of vision caused by manual inspection; the use of machine vision technology can also accurately locate the workpiece, allowing the machine to adapt to the position of the workpiece for processing, eliminating the trouble of repeated clamping of the workpiece, improving the processing accuracy to ensure quality, and can also perform continuous and precise operations to speed up work efficiency.

Application of CCD visual inspection in laser processing industry

1. Laser cutting

Machine vision is used for laser cutting. Guided laser cutting can make the product cutting line precise, the edge smooth, and easily cut out any desired shape and size. Laser cutting is used in the automotive industry, semiconductor industry, mold industry, raw material industry, consumer goods manufacturing industry, and aerospace industry. Specific applications include wafer cutting, FPC flexible circuit board cutting, cloth label and leather cutting, automotive parts cutting.

2. Laser welding

Laser welding occupies an important position in precision instrument welding due to its advantages of no slag pollution and no deformation, and machine vision guidance makes it even better. Specific applications include automotive body steel plate welding, battery welding, pacemakers, sealed relays, etc.

3. Laser marking

Laser marking is widely used in various materials and almost all industries. Machine vision-guided positioning is aimed at fragile materials, small target size, high positioning accuracy requirements, and continuous large-scale marking operations, which can effectively improve production efficiency and ensure stable product quality. Specific applications include IC marking, electronic consumer product marking, automotive parts marking, and shoe upper marking.

4. Laser micromachining

Laser micromachining includes fine processing methods such as scribing and resistance adjustment, which will produce large errors in human eye judgment. Machine vision can clearly locate the processing area and guide the laser to work, minimizing errors as much as possible. Specific applications include laser resistance adjustment and thin film solar cell scribing.

The introduction of machine vision technology in the laser processing industry has effectively improved the accuracy, intelligence and automation performance of laser processing equipment, met the quality requirements of mass and large-scale production in modern industry, reduced the production of defective products, saved costs, and promoted the long-term development of enterprises.

Intsoft Tech’s CCD machine vision inspection and positioning system uses image sensors to replace human eyes, accurately detects surface defects and defects of objects with 99.97% accuracy, and counts, classifies and analyzes defect information, optimizes production process control, grades products, and classifies qualified and unqualified products, thereby improving customer trust and satisfaction.