Ceramic appearance machine vision inspection equipment is mainly used to automatically check the appearance quality of ceramic products. It uses high resolution cameras and advanced image processing algorithms to fully scan the ceramic surface and detect whether the product has defects such as cracks, bubbles, scratches, uneven color, etc. This equipment can quickly and objectively inspect a large number of ceramic products, greatly improving inspection efficiency and accuracy. It is indispensable and important equipment in modern ceramic production. It can be applied to the production quality control of various ceramic products, such as building ceramics, artistic ceramics, household ceramics, etc.

Machine vision detection features

1. High-precision detection: Through high-resolution image acquisition equipment and precise algorithms, it is possible to accurately detect defects, defects, cracks, etc. on the appearance of ceramic products.

2. Multi-view detection: It can be detected from multiple angles and light sources to ensure a comprehensive evaluation of the appearance quality of ceramic products.

3. Automated detection: Ceramic appearance detection can be performed with the help of automated equipment to improve detection efficiency and accuracy.

4. Quick feedback: It supports the rapid generation of detection reports and results feedback to help production personnel adjust the production process in a timely manner.

5. Data analysis: Detection data can be analyzed and counted to provide a basis for quality management and production optimization.

Applications

1. Ceramic manufacturing industry: used for appearance quality inspection of ceramic products such as ceramic tiles, ceramic tableware, and ceramic crafts.

2. Construction industry: used for appearance inspection of building ceramic materials like ceramic tile, to ensure product quality and appearance consistency.

3. Home decoration: used for appearance quality inspection of ceramic home decoration products like vases, statues, to ensure the perfect product appearance.

4. Artwork manufacturing: used for appearance inspection of ceramic artworks to ensure artwork quality and appearance.

Ceramic appearance visual inspection technology helps to improve the appearance quality and production efficiency of ceramic products, while reducing the defective product rate.

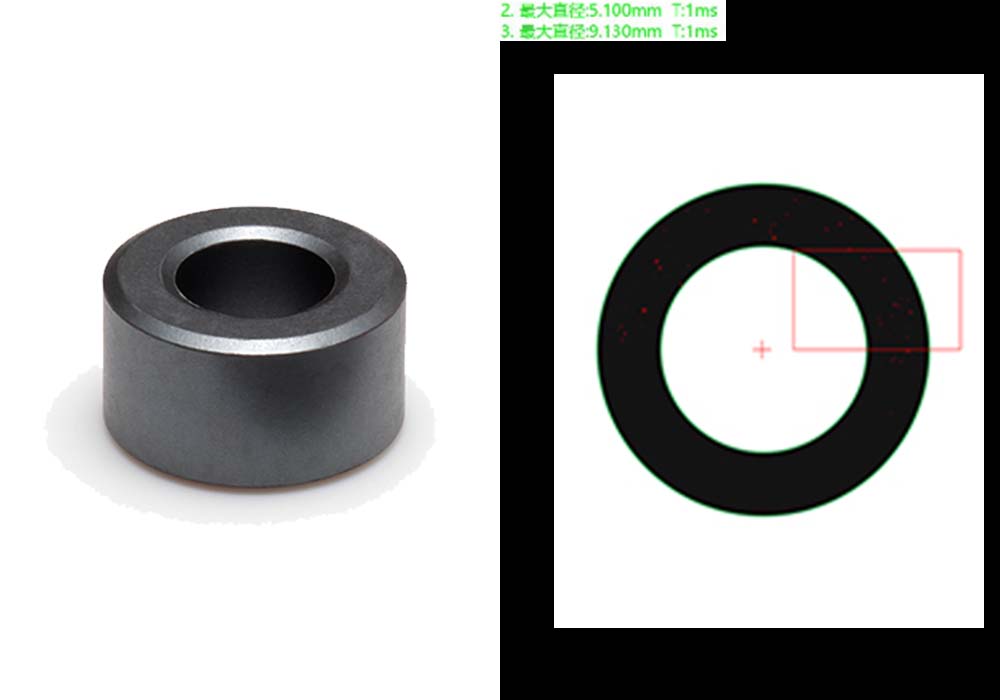

Detection Items:

Cylindrical ceramic fittings, detected items must be clearly visible under the image for detection.

Detection process:

Top view

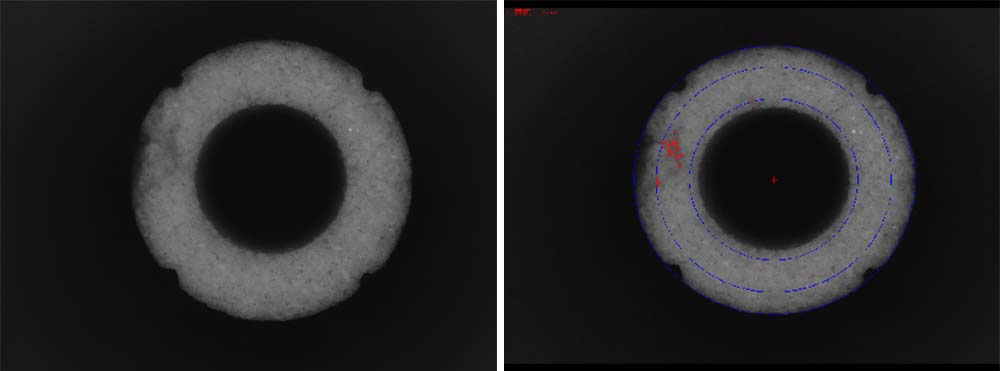

Positive light inspection good product analysis image: OK —

Positive light inspection defect product analysis image: NG, defect cause: incomplete filling —

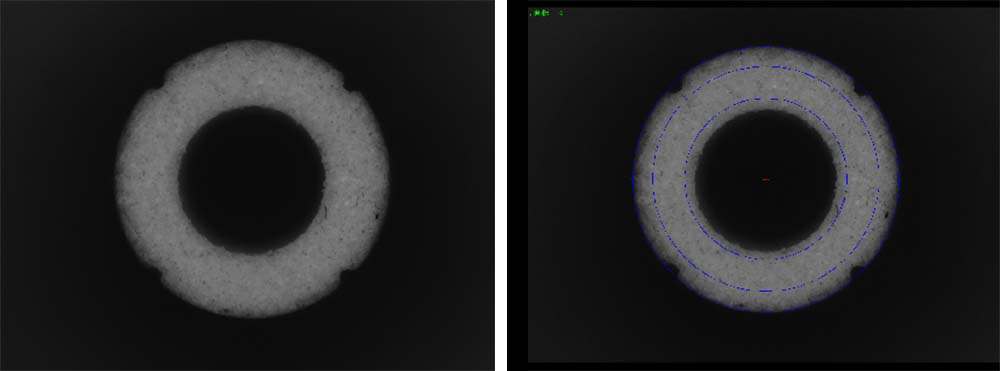

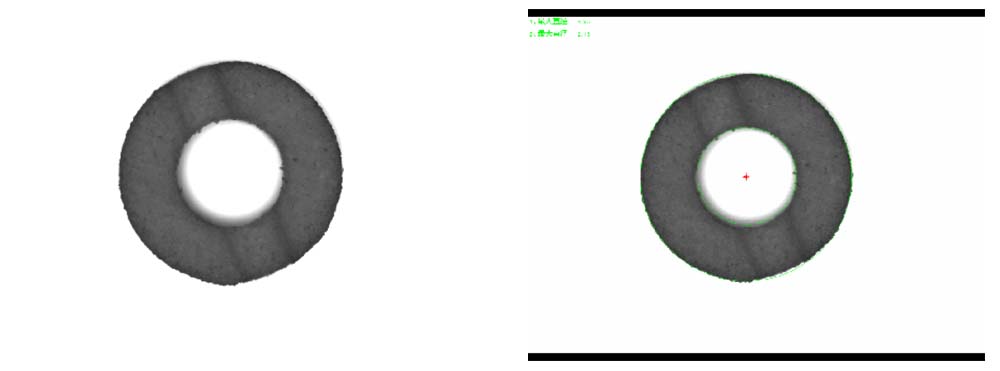

Backlight inspection good product analysis image: OK —

Backlight inspection defect product analysis image: OK —

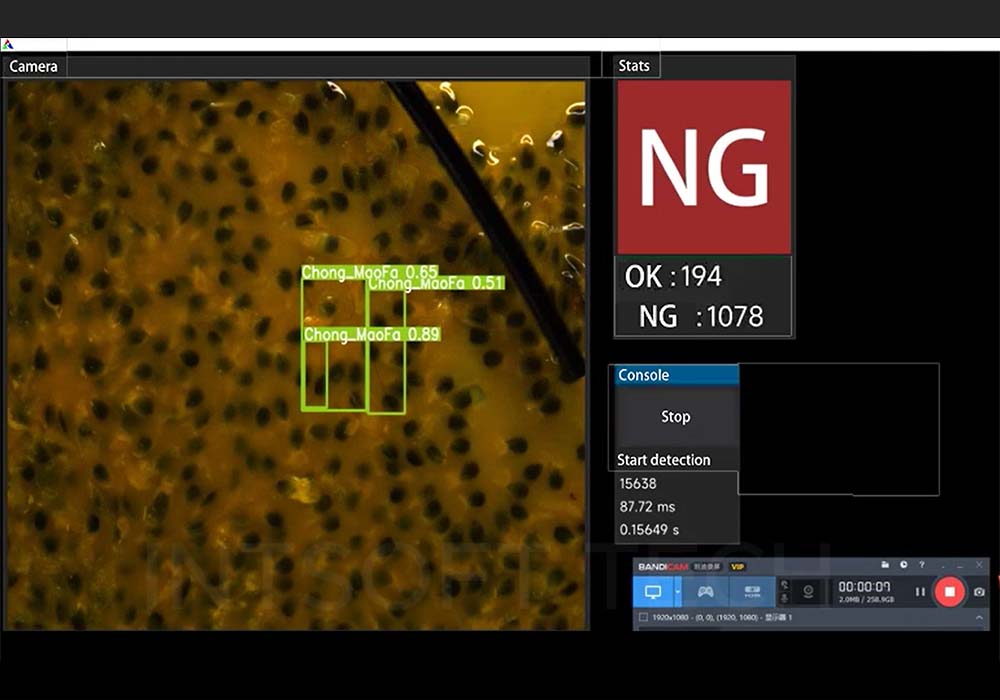

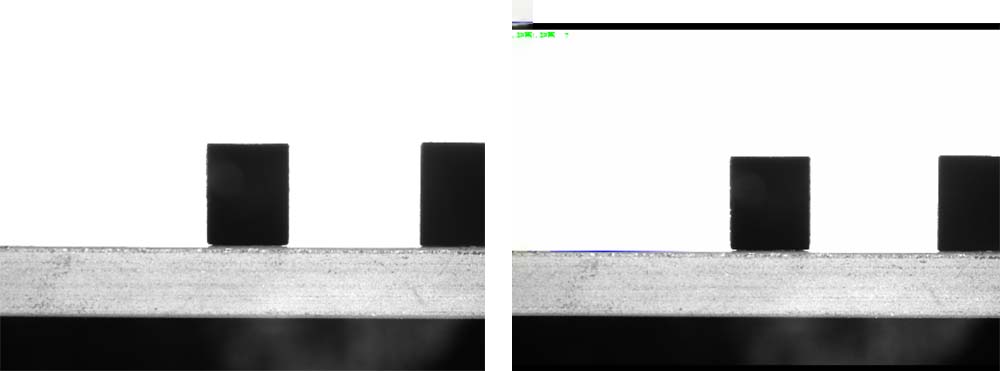

Bottom view

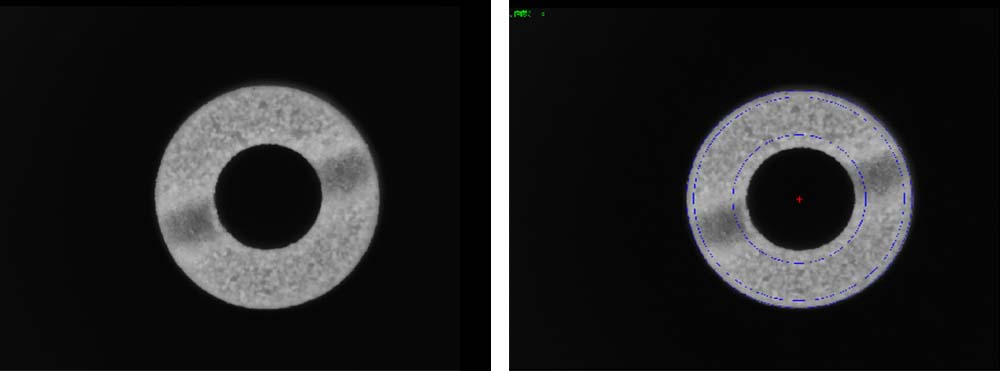

Positive light inspection good product analysis image: OK —

Positive light inspection defect product analysis image: NG, defect cause: uneven surface —

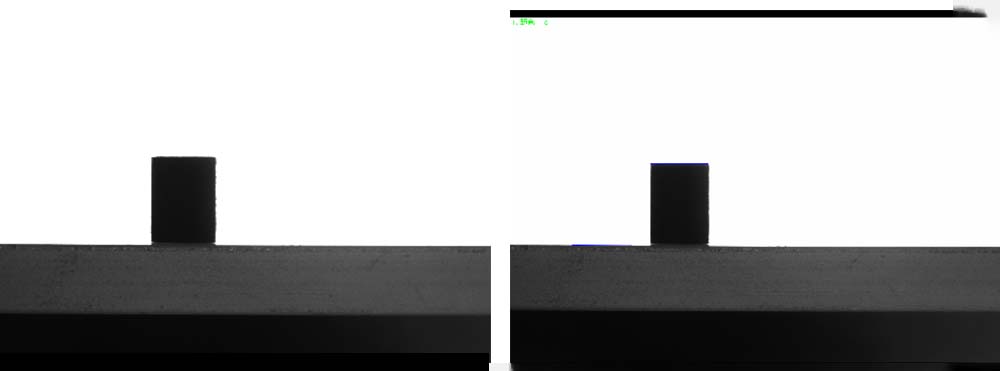

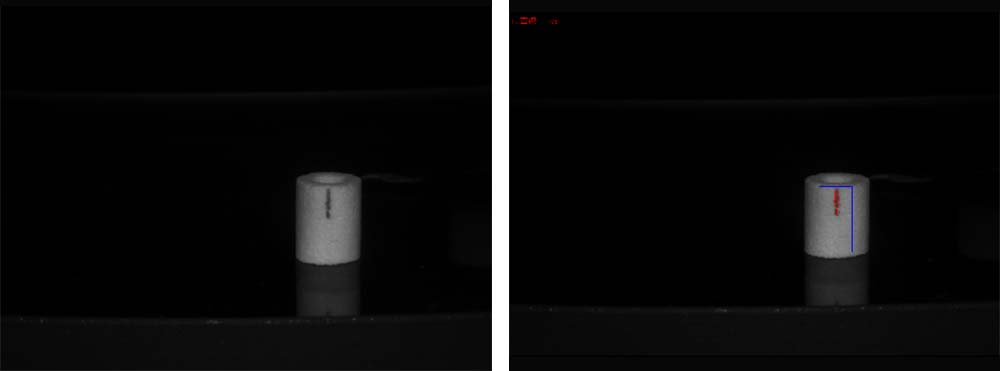

Side view

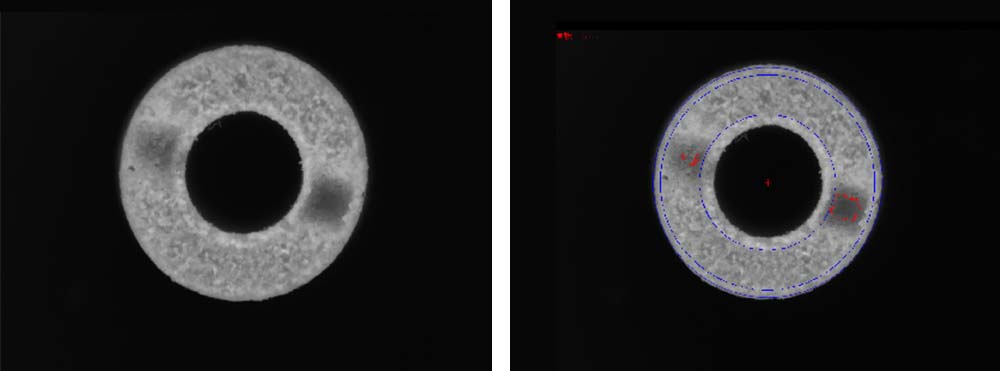

Backlight+positive light inspection defect product analysis image: NG, defect cause: stain —

Backlight+positive light inspection defect product analysis image: NG, defect cause: incomplete filling —

Backlight+positive light inspection good product analysis image: OK, Correct height —

Backlight+positive light inspection good product analysis image: OK, Correct height —