The magnetic ring and the connecting cable form an inductor, which is a commonly used anti-interference component in electronic circuits. It has a good shielding effect on high frequency noise, so it is called an absorption magnetic ring. Because it is usually made of ferrite material, it is also called a ferrite magnetic ring (magnetic ring for short). The magnetic ring has different impedance characteristics at different frequencies. Generally, the impedance is very small at low frequencies, and when the signal frequency increases, the impedance of the magnetic ring increases sharply. It can be seen that the role of inductance is so great. As we all know, the higher the signal frequency, the easier it is to radiate. In general, signal lines do not have a shielding layer. These signal lines become good antennas for receiving various messy high-frequency signals in the surrounding environment. These signals are superimposed on the original transmitted signals, and may even change the original useful signals, seriously interfering with the normal operation of electronic equipment. Therefore, reducing electromagnetic interference in electronic equipment has become a problem that must be considered. Under the action of the magnetic ring, normal and useful signals can pass smoothly, and high frequency interference signals can be well suppressed, and the cost is low. The demand for magnetic rings is huge and the quality requirement is high, so it is necessary to carry out appearance inspection during production to ensure the quality is good.

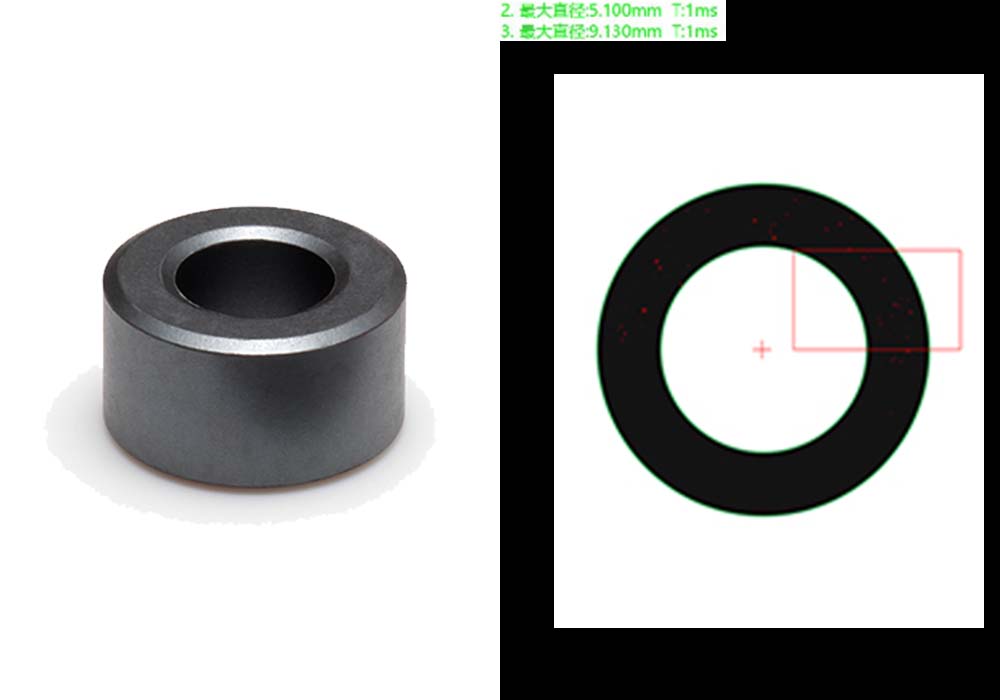

Following is the case study of magnetic rings inspection.

Inspection machine detail:

Machine Model: Magnetic material machine vision inspection device Intsoft-569

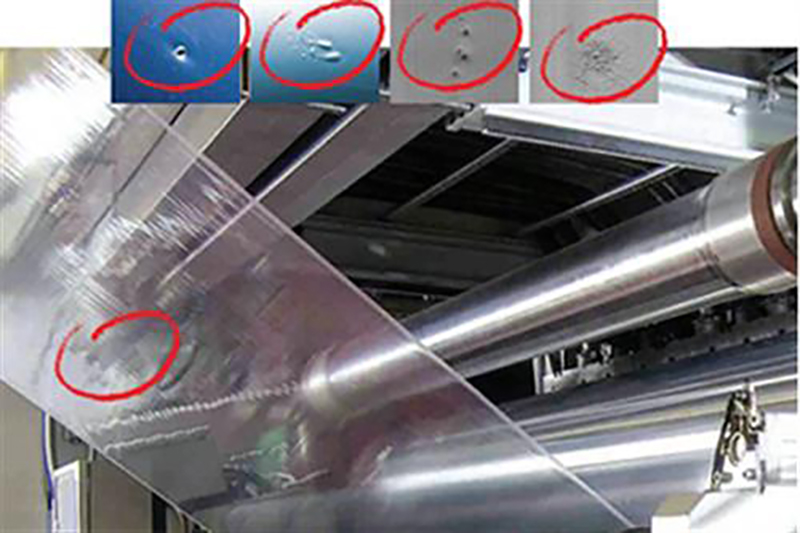

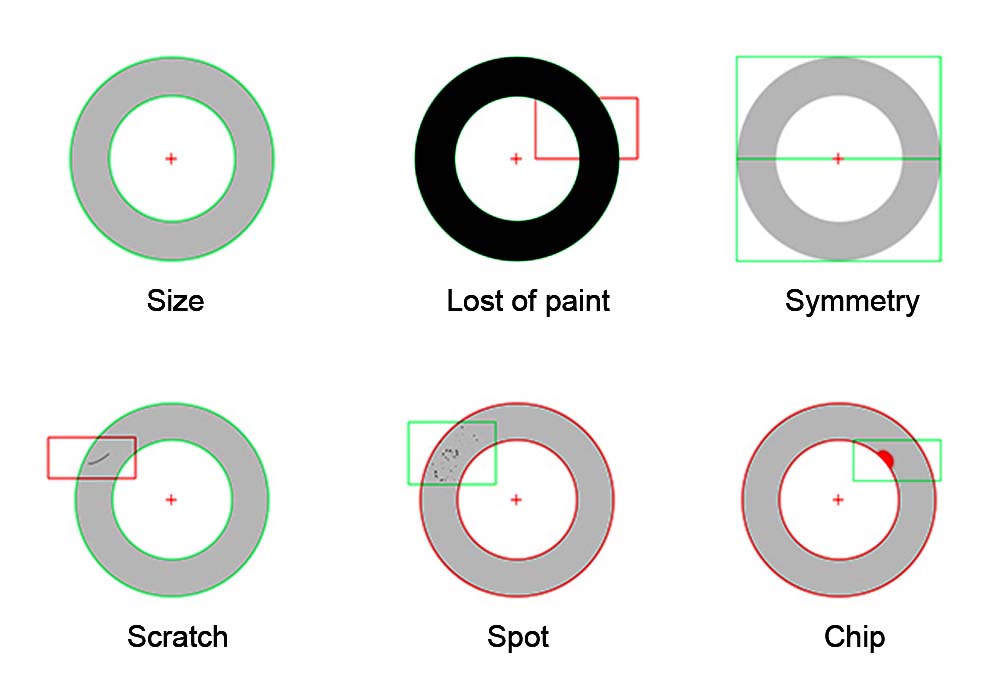

Inspection items: Size, Chip, Edge breakage, Burr, Scratch, Dent, Mixed material, Loss of paint, Symmetry, Spot.

Inspection speed: 180-600 pcs/min

Detectable product: Magnetic cores, Magnets, Magnetic rings, Inductors, Capacitors, Resistors

Equipment functions: The magnetic material visual inspection equipment has the functions of automatic loading, automatic positioning, automatic detection, automatic sorting, automatic unloading, intelligent measurement and control, automatic statistics, AI deep learning, the whole process is automated.

Inspection image:

Inspection condition:

Configuration: top view, side view, bottom view (inspection view can be increased or decreased according to inspection items)

Inspection range: 360° full inspection

Applicable specifications: outer diameter φ1.0mm-φ20.0mm; height 2.0mm -25.0mm

Inspection speed: 300-800pcs/min

Inspection accuracy: up to ±0.001mm

Software system: Intsoft Tech

Power supply voltage: 220V 50Hz

Rated power: 500KW

Air pressure: 0.4-0.8MPA

Working temperature: 0℃-45℃