Ceramic tubes are insulating, high temperature resistant, waterproof and wear resistant, and are suitable for use as external protective materials at the branching of wires. When it comes to the protection of these key parts of the wires, the quality of ceramic tubes must be well controlled to avoid casualties caused by wire leakage.

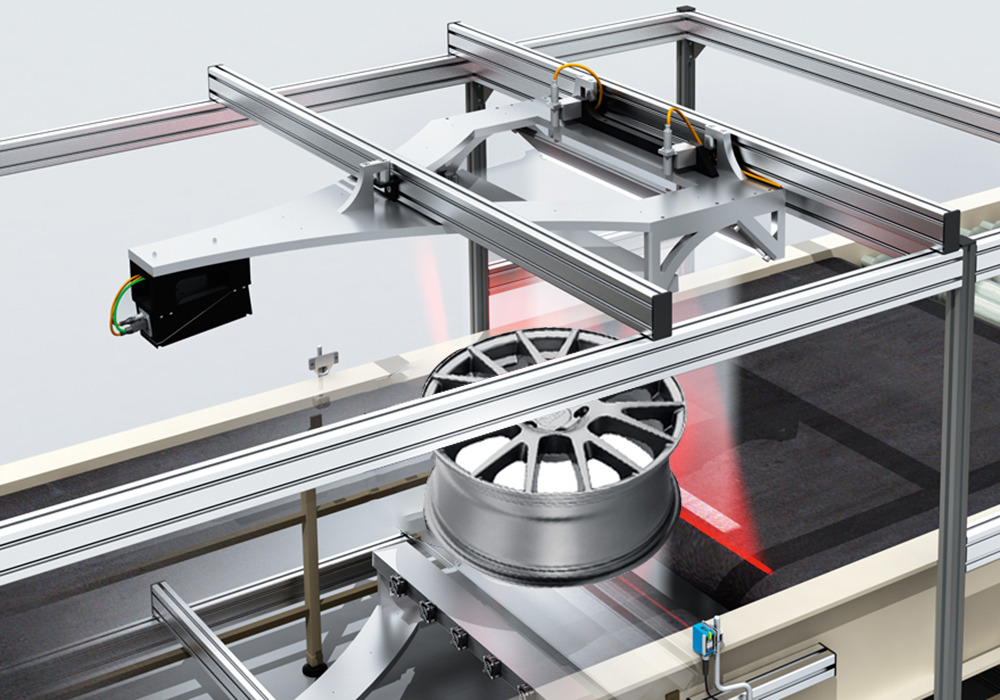

Ceramic appearance inspection machine can perform machine vision inspection on the appearance of ceramic tubes, and quickly detect various defects such as missing edges, incomplete filling, cracks, size errors, color abnormalities, etc. of ceramic tubes, and can reach an inspection speed of more than 200 per minute.

Equipment features

High-speed performance: Through rapid image acquisition and processing, it can realize rapid inspection of products, which is suitable for the needs of high-speed production lines.

High precision: Using high resolution cameras and advanced image processing algorithms, it can accurately identify subtle defects in product appearance and improve detection accuracy.

Automation: Realize automated product inspection processes without manual intervention, reduce labor costs and improve production efficiency.

Versatility: It can detect a variety of appearance defects, such as scratches, color inconsistencies, blemishes, etc., and can perform various analyses such as size measurement and shape recognition.

Real-time monitoring: It can monitor the appearance quality of products in real time, and promptly alarm and handle abnormal products to ensure that product quality meets standards.

Data recording and analysis: Record test data and results, conduct data analysis and statistics, help companies monitor product quality trends, improve production processes and quality management.

Flexibility: It can be customized and adjusted according to different product types and inspection requirements, and is suitable for appearance quality inspection in various industries, such as electronics, automobiles, food, etc.

Main functions

Defect detection: Identify and detect defects on the product surface, such as scratches, blemishes, cracks, etc., to ensure the appearance quality of the product.

Dimension measurement: Accurately measure the size, shape and position of the product to ensure that the product meets the specifications.

Color recognition: Detect the color of the product surface to ensure color consistency and accuracy.

Shape recognition: Identify the shape characteristics of the product, including contours, angles, curvatures, etc., to ensure the correct shape of the product.

Positioning: Locate the position of the product to ensure that the product is correctly positioned or aligned.

Barcode recognition: Identify the barcode or QR code on the product to track product information or perform inventory management.

Surface quality assessment: Evaluate the quality of the product surface and detect surface finish, flatness and other characteristics.

Abnormal detection: Detect and alarm abnormal products, such as foreign objects, misalignment, damage, etc., to ensure the normal operation of the production line.

Machine structure

Name: High-speed ceramic tube inspection machine

Overall dimension: 950*850*1850mm

| Visual inspection software | Intsoft customized

|

| Industrial Computer

|

Intsoft Tech Customized

|

| Displayer | PHILIPS 19″ LCD displayer |

| Industrial camera | Sony Industrial Camera |

| Camera adjustment servo module | Intsoft Tech customized |

| Industrial lens | FA high definition optical industrial lens

|

| Light source | customized adaptive optical light source |

| Inspection platform | professional optical glass stage |

| Servo motor | Panasonic |

| Control system | Intsoft Tech customized |

| PLC Motion Collaboration | Panasonic |

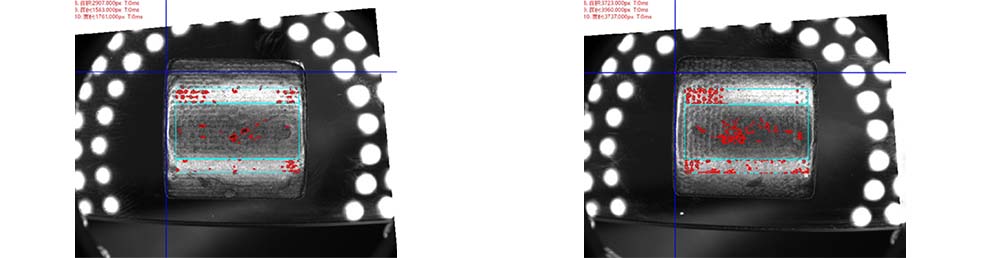

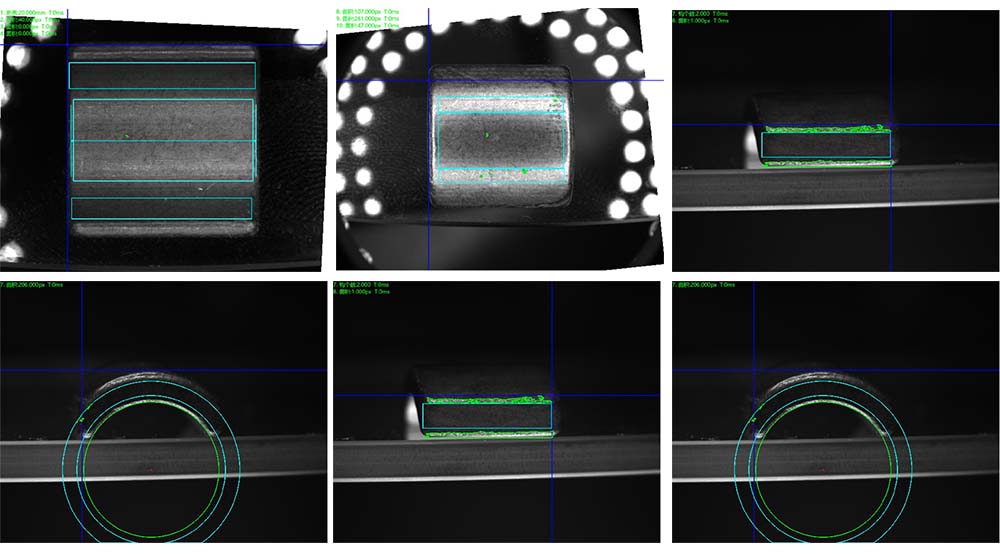

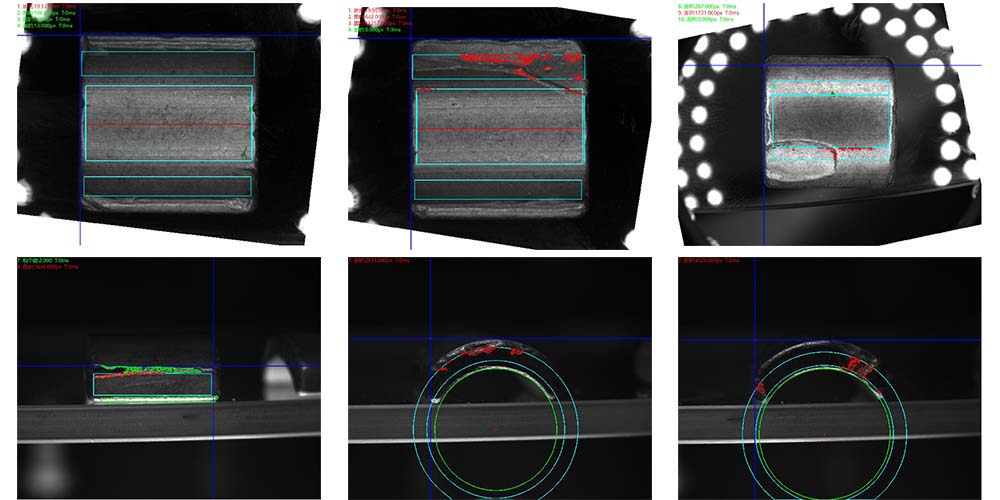

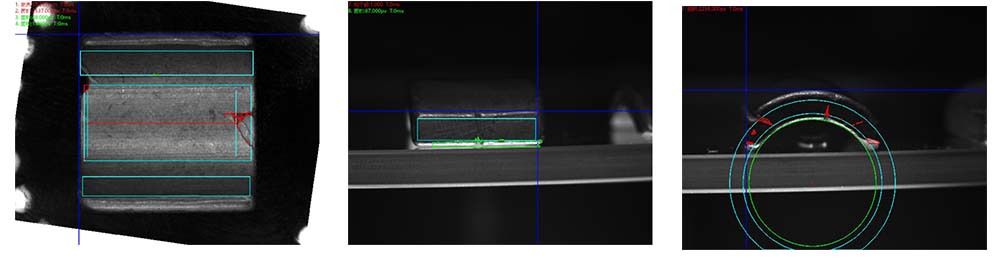

Inspected image

Images of good products

Integrity inspection — incomplete

Crack inspection

Pitting inspection