Ceramic tubes are insulating, high temperature resistant, waterproof and wear resistant, and are suitable for use as external protective materials at the branching of wires. When it comes to the protection of these key parts of the wires, the quality of ceramic tubes must be well controlled to avoid casualties caused by wire leakage.

Ceramic appearance inspection machine can perform machine vision inspection on the appearance of ceramic tubes, and quickly detect various defects such as missing edges, incomplete filling, cracks, size errors, color abnormalities, etc. of ceramic tubes, and can reach an inspection speed of more than 200 per minute.

Machine structure

Name: High-speed ceramic tube inspection machine

Overall dimension: 950*850*1850mm

| Visual inspection software | Intsoft customized

|

| Industrial Computer

|

Intsoft Tech Customized

|

| Displayer | PHILIPS 19″ LCD displayer |

| Industrial camera | Sony Industrial Camera |

| Camera adjustment servo module | Intsoft Tech customized |

| Industrial lens | FA high definition optical industrial lens

|

| Light source | customized adaptive optical light source |

| Inspection platform | professional optical glass stage |

| Servo motor | Panasonic |

| Control system | Intsoft Tech customized |

| PLC Motion Collaboration | Panasonic |

Image of detected item

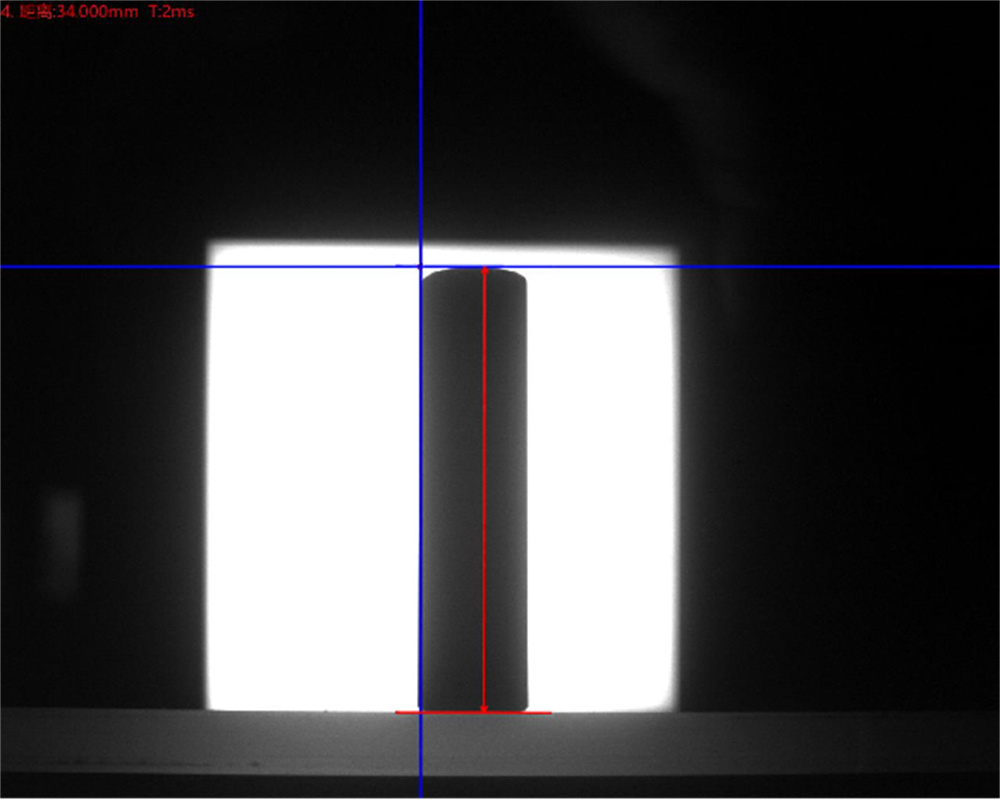

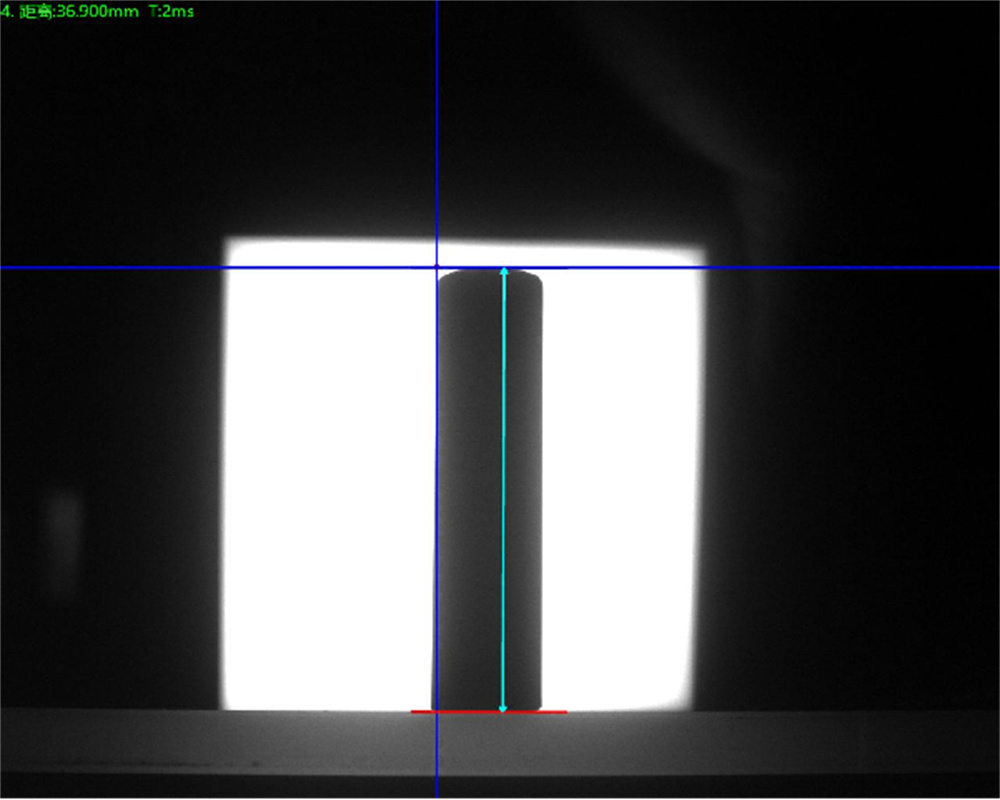

Side view detection

Side view backlight defect product analysis image: NG cause of defect: Wrong height

Side view backlight good product original image: OK

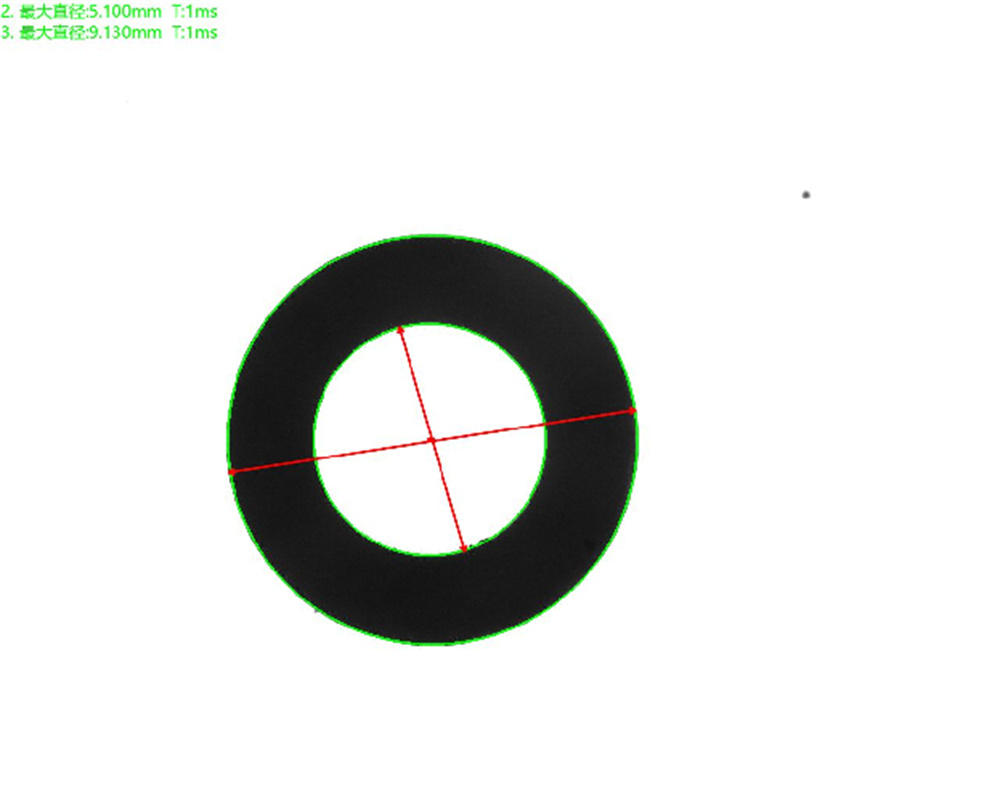

Top view detection