ITO Conductive Glass Deep Learning Visual Defect Detection System

ITO conductive glass is made on the basis of sodium-calcium or borosilicate substrate glass by magnetron sputtering on a layer of indium tin oxide (commonly known as ITO) film.

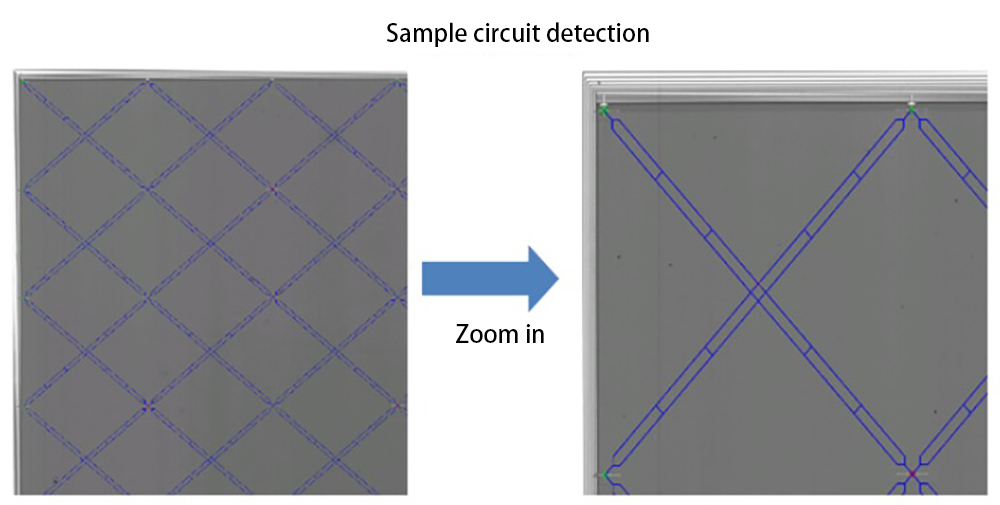

Detection program

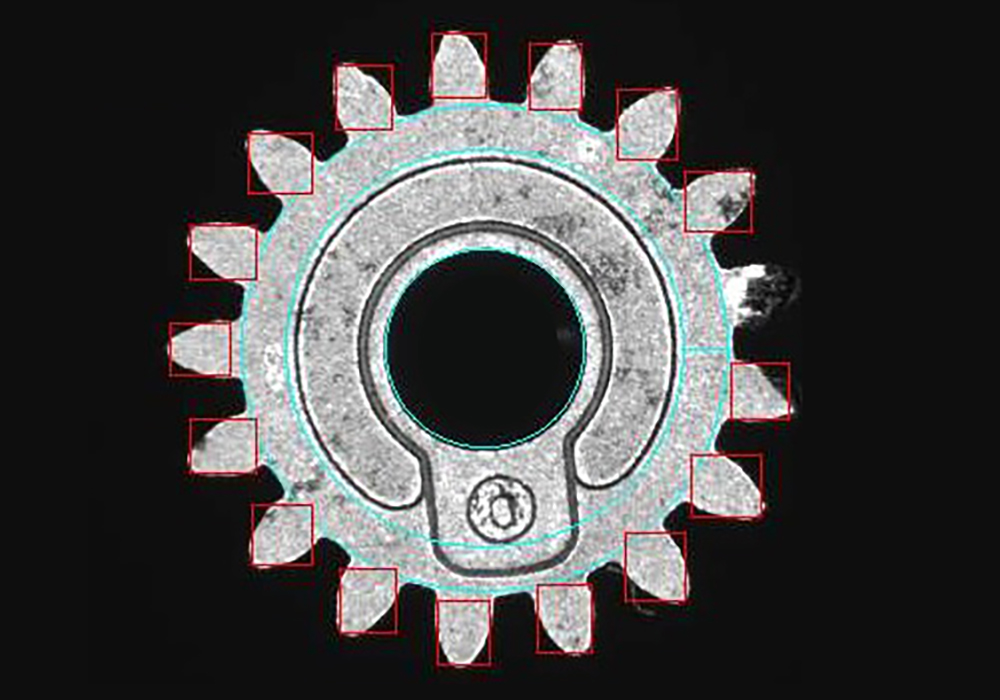

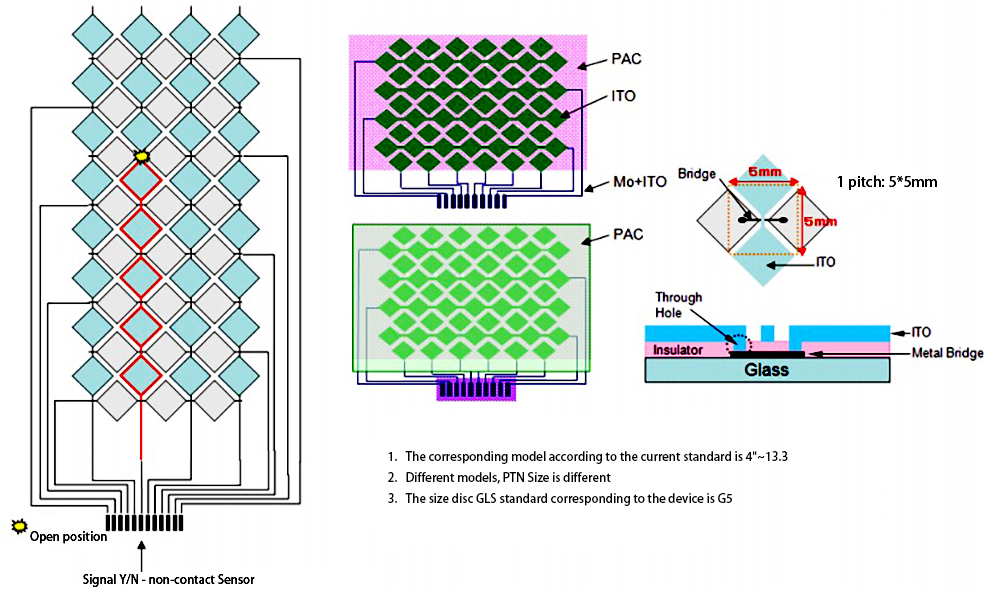

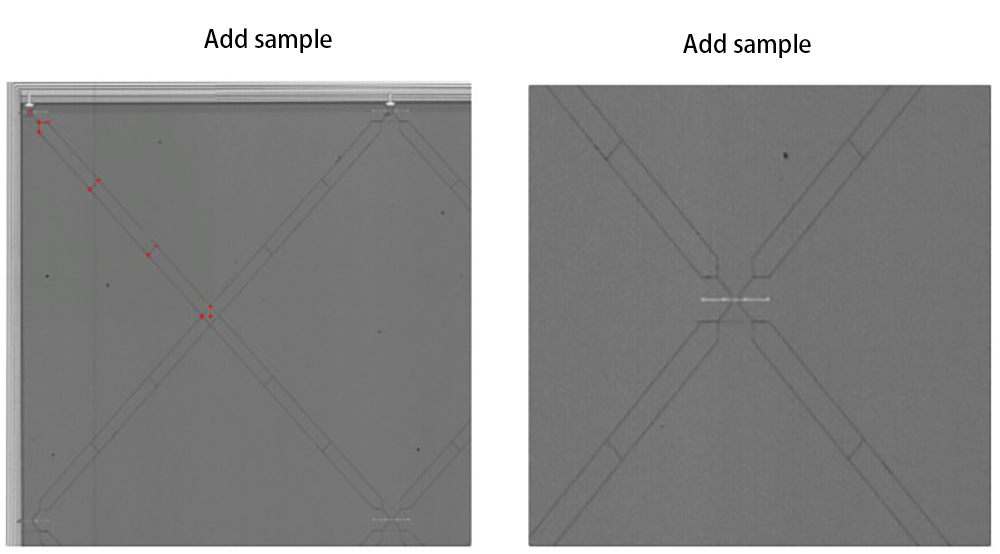

Purpose : To detect open/short defects in ITO and defects in the bridge area.

Condition : Disc Glass (730*920) with 1 pitch for Size G5 equipment.

Condition: 5mm*5mm ~ Maximum 8mm*8mm, Distance between CF backside and backside inspection patterns: 30mm

Key point of ITO conductive glasses deep learning detection:

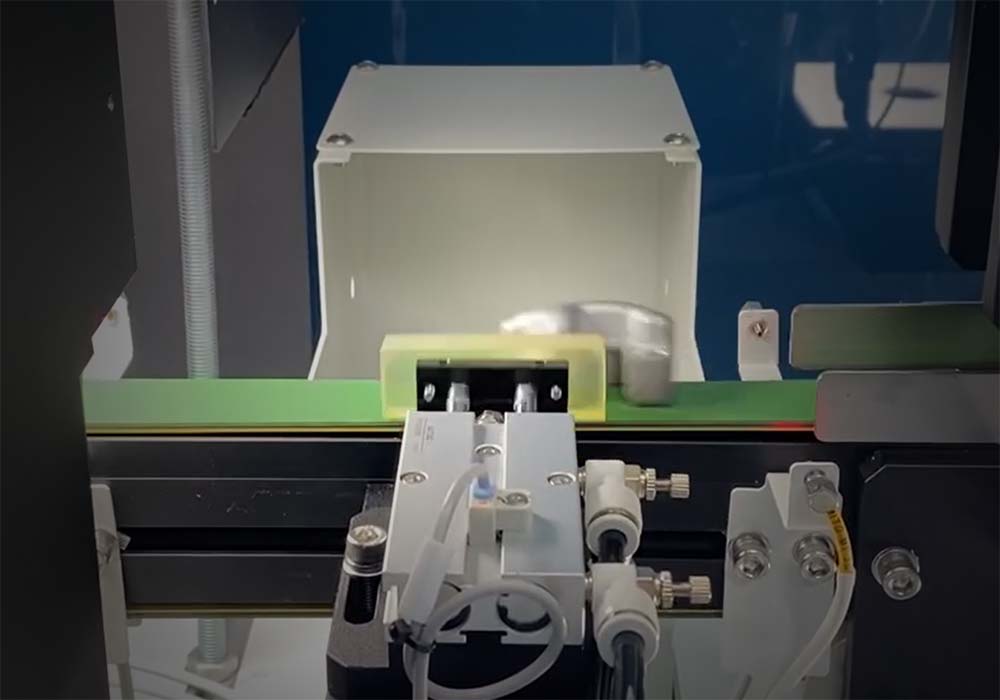

Image Acquisition:

Use high-resolution industrial cameras to capture detailed images of the ITO conductive glass samples.

Ensure consistent and optimal lighting conditions to minimize environmental interference.

Calibrate the camera system to obtain accurate and undistorted images.

Image Preprocessing:

Apply image preprocessing techniques such as noise reduction, contrast enhancement, and normalization.

Perform image segmentation to isolate the regions of interest (i.e., the ITO glass surface).

Extract relevant visual features from the preprocessed images, such as texture, color, and geometric properties.

Deep Learning Model:

Develop a deep neural network architecture tailored for ITO glass defect detection.

Common models used include Convolutional Neural Networks (CNNs), which are effective in extracting visual features from images.

Train the deep learning model using a labeled dataset of ITO glass images, including both defective and non-defective samples.

Fine-tune the model’s hyperparameters and architecture to optimize its performance for the specific ITO glass defect detection task.

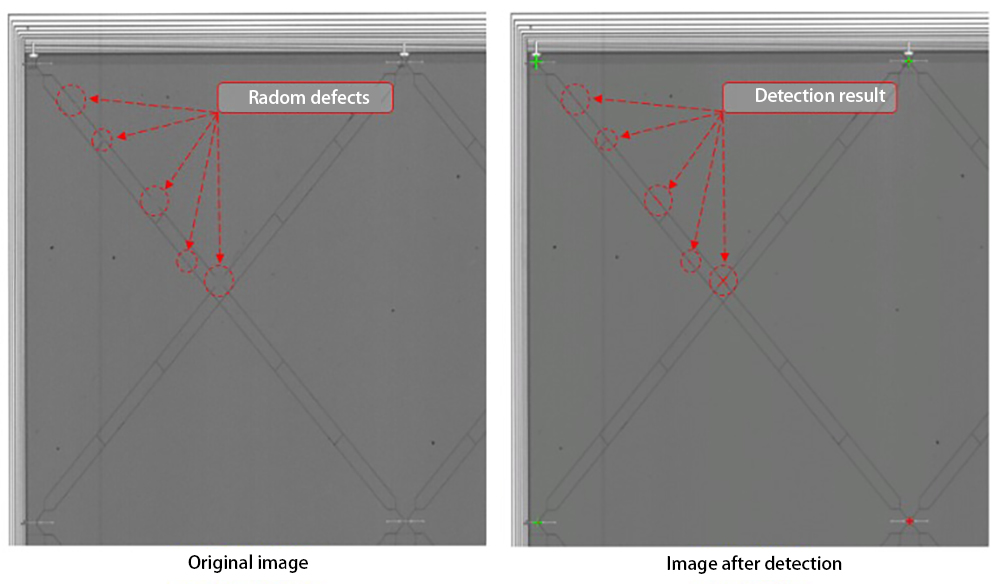

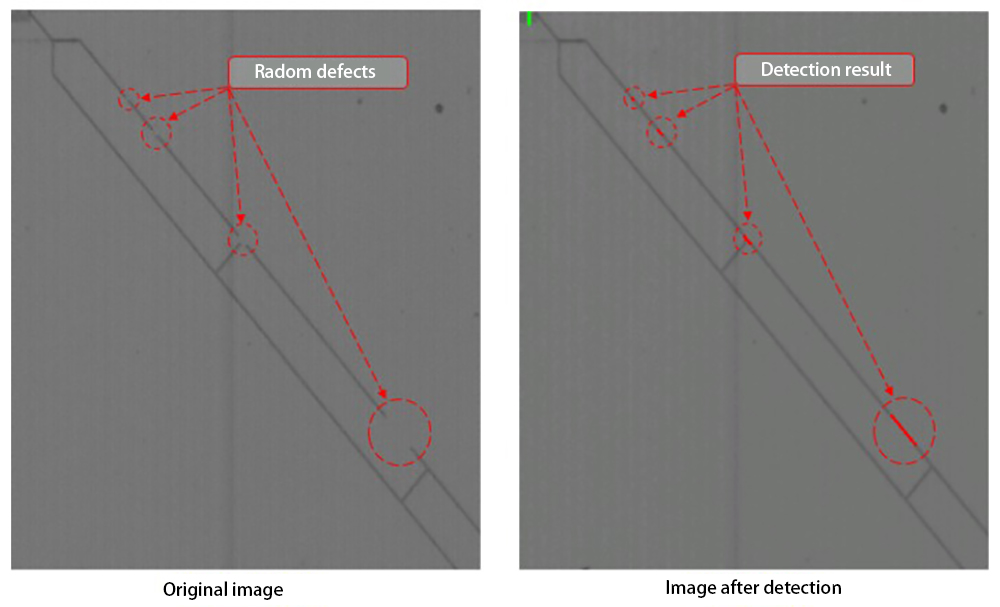

Defect Classification:

Use the trained deep learning model to classify each ITO glass sample as either defective or non-defective.

Identify the types of defects present, such as scratches, discoloration, cracks, or other surface irregularities.

Localize the position and extent of the detected defects within the glass samples.

Model Deployment and Monitoring:

Integrate the deep learning-based defect detection system into the ITO glass manufacturing workflow.

Monitor the system’s performance and continuously refine the model as new data becomes available.

Implement quality control procedures to ensure the system’s reliability and accuracy over time.