Traditional defect detection methods for artificial visual inspection methods. This artificial visual inspection method must be carried out under bright light conditions. Not only is the inspector’s eyes very pernicious, but there is a strong subjectivity. The spatial resolution and detection duration of the human eye is limited, the detection of uncertainty, easy to produce ambiguous, inefficient and other shortcomings, it has been very difficult to meet the requirements of modern industrial high-speed, high-resolution detection.

With the rapid development of electronic technology, image sensing technology and computer technology, the use of surface defects based on optical image sensing automatic optical (visual) detection technology to replace manual visual detection of surface defects has gradually become an important method of surface defect detection, because this method has the advantages of automation, non-contact, fast speed, high precision, high stability.

Intsoft Technology defection program

Purpose: To detect defects such as stains, scratches, corrugations, bubbles, etc. on the surface of eyeglasses.

Criteria: Superior grade, good grade and qualified grade according to defects.

Superior grade: within Φ35 of part A, Φ35-Φ55 of part B, and outside AB area of part C.

Good grade: within Φ30 of A part, Φ30-Φ50 of B part, and outside of AB area of C part.

Qualified grade: within Φ30 of A part, Φ30-Φ50 of B part, and outside of AB area of C part.

(Each specification is defined by the size and number of defects of different grades, such as for a superior grade, there is one white spot with a size of 0.05mm in Part B.)

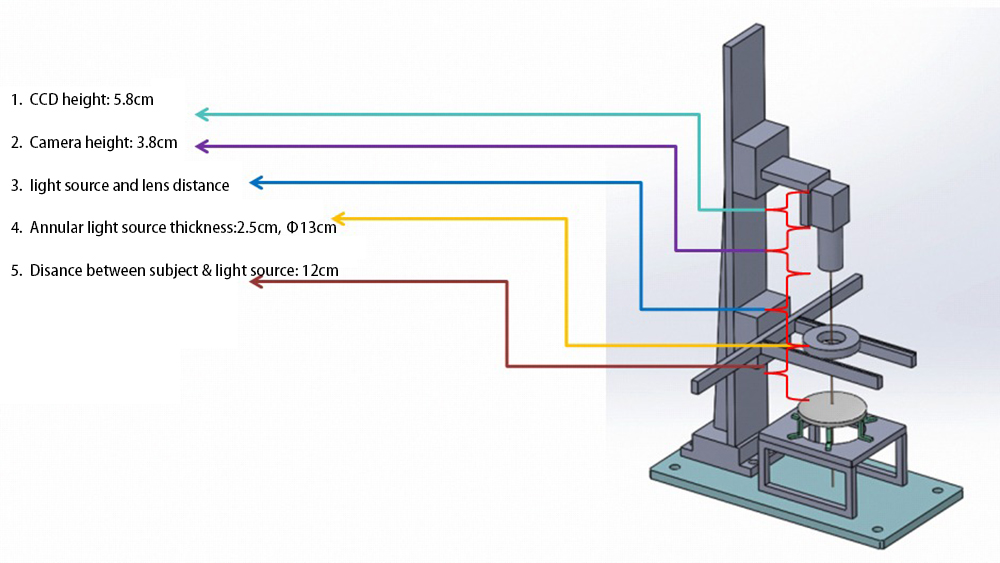

Detection Program

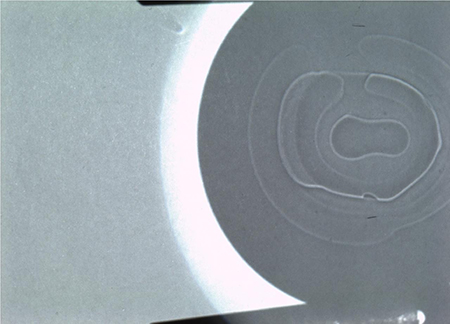

Different defects on the lens

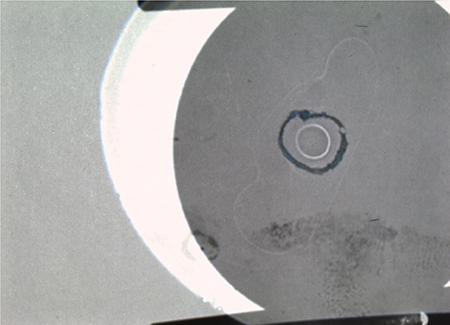

Indentation:  Bubble:

Bubble:

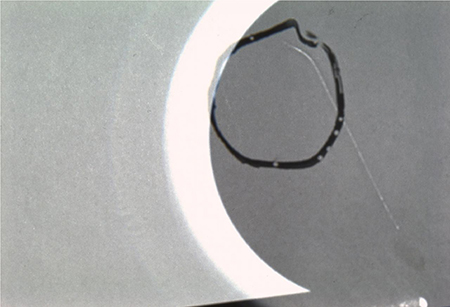

Scratch:

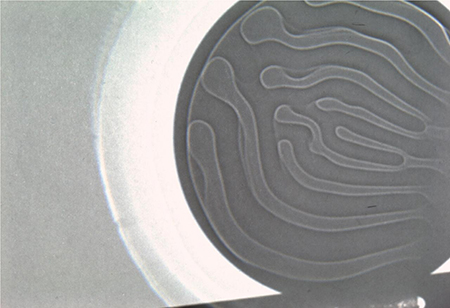

Corrugate:

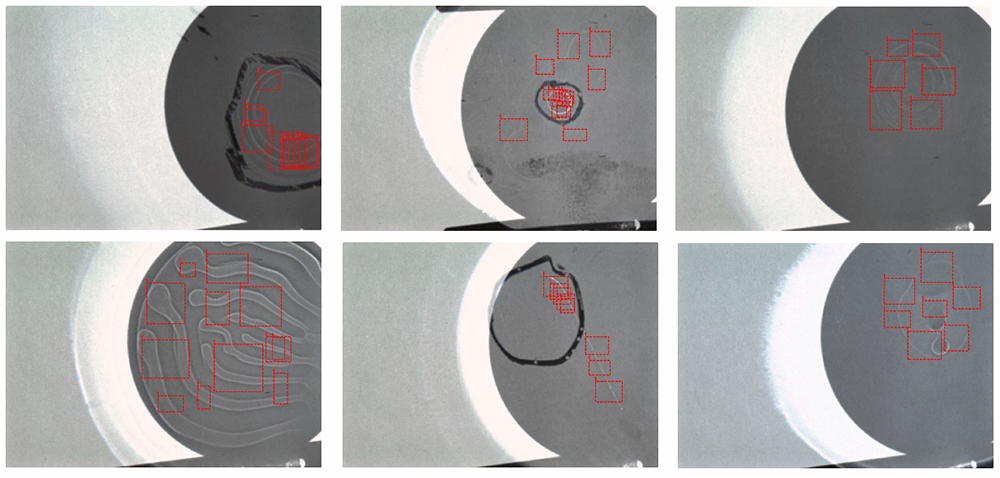

Detection results:

99.5% of defects were detected after collecting a large number of defect features. 10 micron defects grade, such as crystal dots and white dots in part A of the Superior grade, can not be imaged due to issues caused by the light source during the primary imaging process.

Additional defection: In weak environmental changes can still be checked by deep learning scratches, ripples, bubbles, debris, and other features, adding different specifications of the sample after the obvious defects, we can also determine the defect classification.