OCR technology plays a very important role in product packaging character recognition. It can realize the automatic high-speed reading of key information such as production date, batch number, expiration date, etc., providing a reliable basis for quality control and product traceability; at the same time, OCR can also effectively identify product anti-counterfeiting marks, which is conducive to combating counterfeit and shoddy goods, maintaining brand image and consumer rights. In addition, OCR technology can also provide information support for intelligent logistics management, improve the efficiency and accuracy of warehousing and distribution, and enhance customer experience by identifying the availability of QR codes on products. It can be said that OCR provides unparalleled advantages for product packaging character recognition and is an effective tool for enterprises to improve efficiency and reduce costs.

Intsoft Tech’s machine vision equipment uses the OCR system to detect the print production date. If it detects missing characters, missing codes, incorrect data, etc., the system will send a signal to the rejection device to reject the product or issue an alarm, providing convenience for the company’s production.

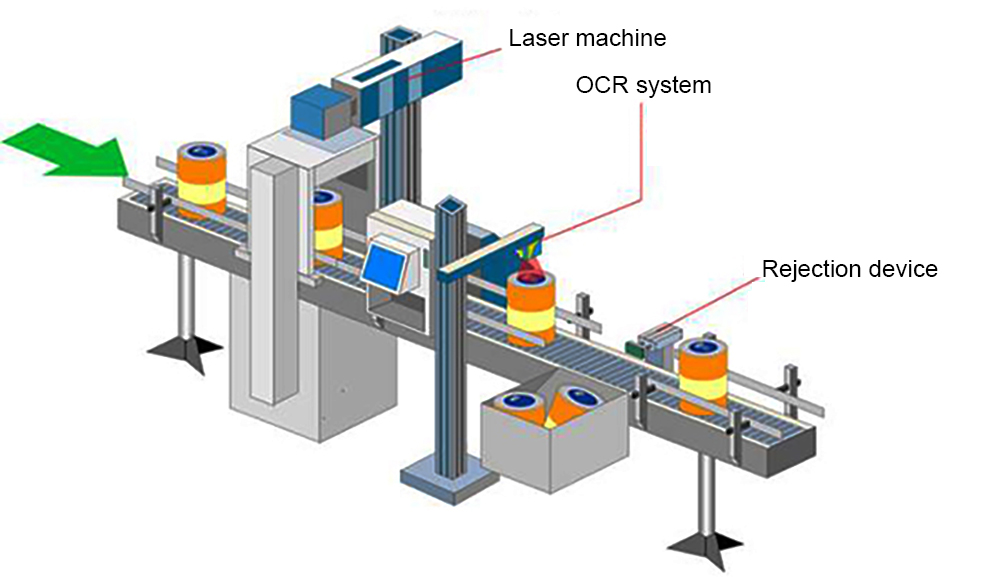

How is OCR system work in the production?

Industrial OCR system procedure:

1. Install an OCR character detection system on the production line.

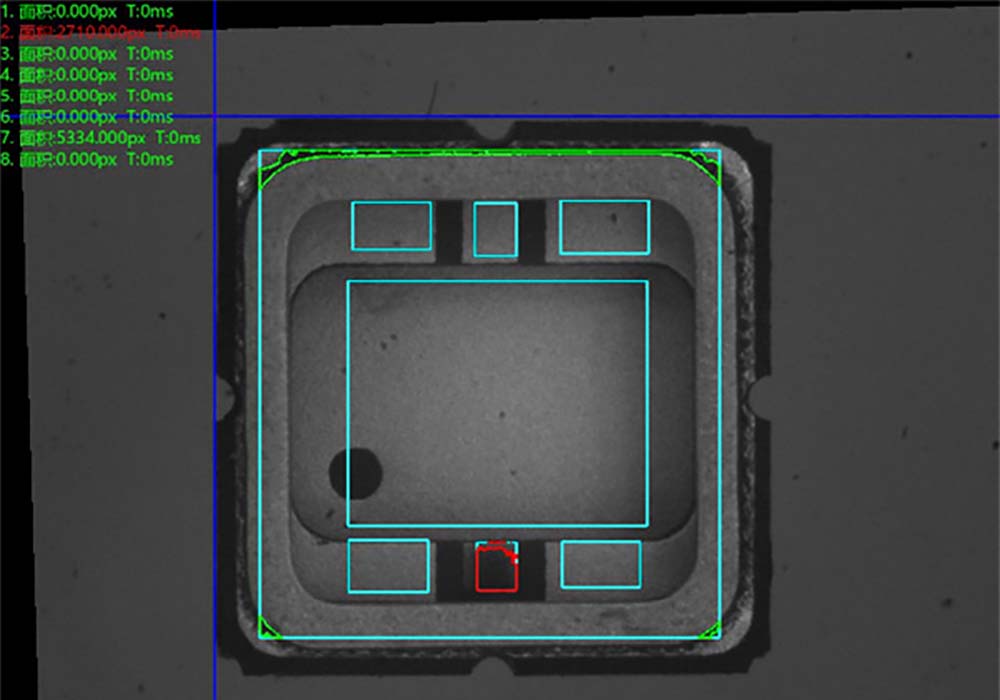

2. When products pass through the detection area, the label characters on the surface are sensed, and the machine vision sensor is triggered by the visual sensor to capture the image of the label and transmit it to the OCR system. The OCR system extracts and analyzes the image and compares it with the preset image to determine whether the product has coding, production batch number and other missing information.

3. When error characters are detected, the system issues an audible and visual alarm and sends a rejection signal.

Product features:

1. High-speed digital CCD imaging technology, 30-10 million pixels, stable dynamic imaging.

2. Unique hybrid algorithm (comprehensive vision field of a variety of high-end OCR reading technology), the widest reading range.

3. Industrial-grade high-performance high-speed controller (Max 2G main frequency).

4. Built-in multiple input and output interfaces for user convenience.

5. Direct drive display and keyboard, greatly simplifying the user’s use cost.

6. Widely used, online inspection of the marking effect of various marking equipment.

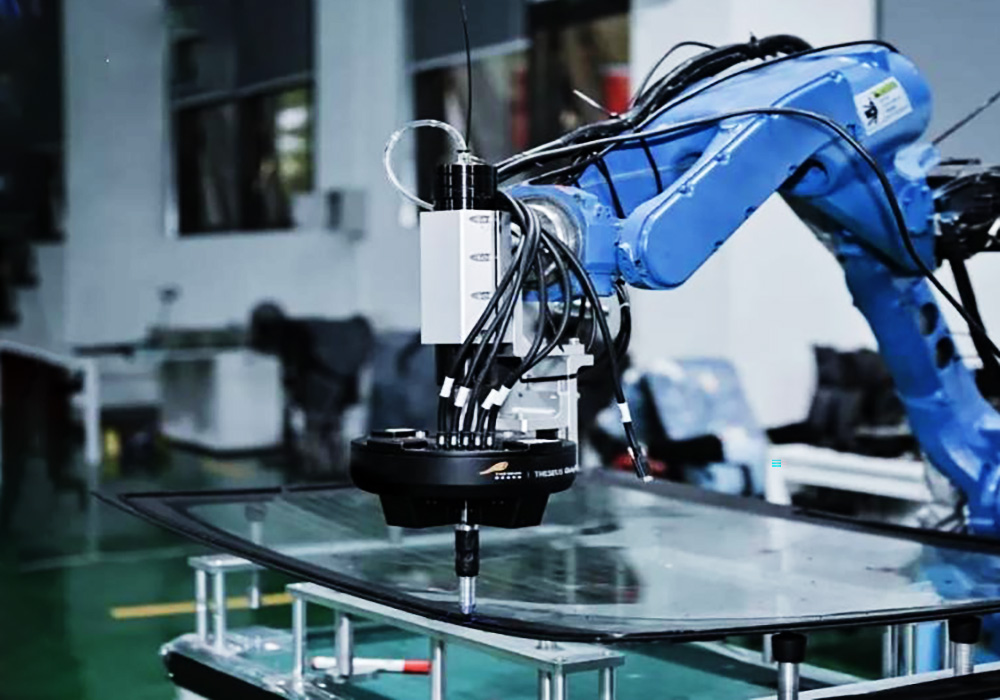

The application of machine vision OCR character detection in food production date is just a drop in the bucket of its industry applications. It can also be used in packaging character visual detection, mobile phone case character detection, characters and barcodes on semiconductor chips, silk screen detection on electronic capacitors, electronic components visual detection, card character visual detection, surface character recognition visual detection, etc. Its application will become more and more extensive in the future, providing greater convenience for our lives.