Ceramic parts are parts or products made of ceramic materials. Ceramics are non-metallic materials, usually made by sintering clay, quartz and other natural materials at high temperatures. Ceramic materials have the characteristics of high temperature stability, corrosion resistance, insulation and high hardness, so they are widely used in various industries and daily necessities.

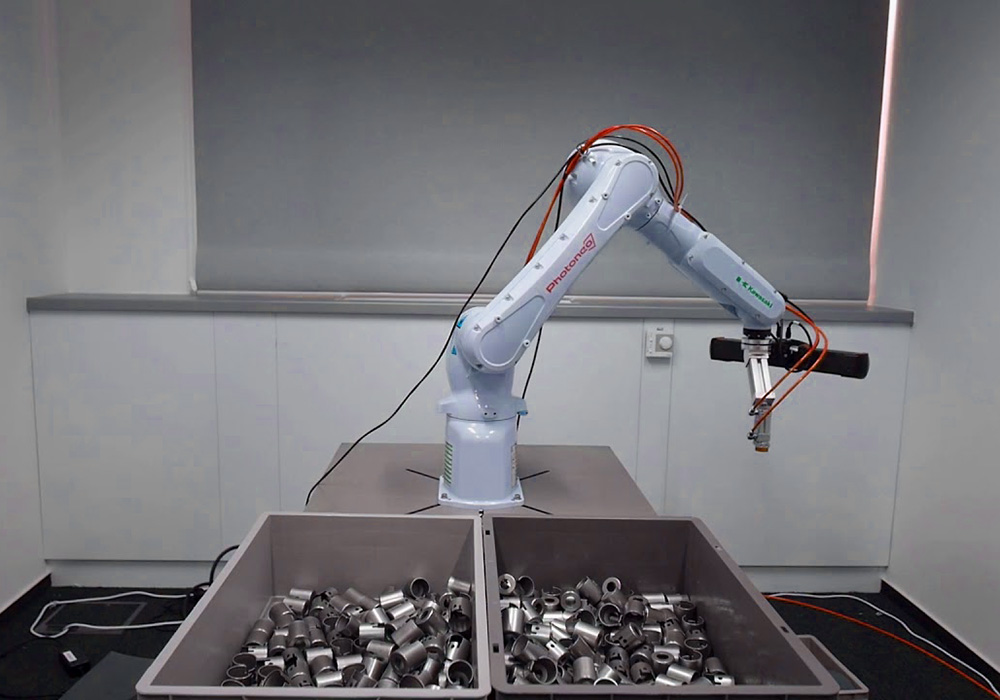

The appearance AOI inspection machine for ceramic parts is a device that uses optical technology to automatically inspect the appearance quality of ceramic products. Using a high resolution camera system and image processing software, it can quickly and accurately detect surface defects, stains, scratches, cracks and other problems with ceramic parts, with inspection efficiency of up to 200 pieces per minute.

Machine vision detection features

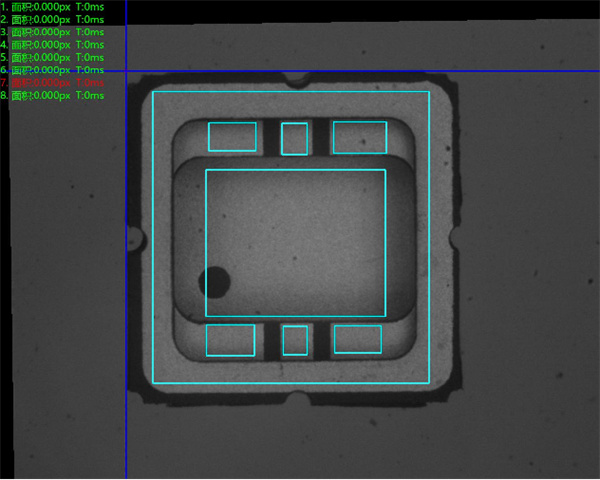

1. High-precision detection: Through high-resolution image acquisition equipment and precise algorithms, it is possible to accurately detect defects, defects, cracks, etc. on the appearance of ceramic products.

2. Multi-view detection: It can be detected from multiple angles and light sources to ensure a comprehensive evaluation of the appearance quality of ceramic products.

3.Automated detection: Ceramic appearance detection can be performed with the help of automated equipment to improve detection efficiency and accuracy.

4.Quick feedback: It supports the rapid generation of detection reports and results feedback to help production personnel adjust the production process in a timely manner.

Data analysis: Detection data can be analyzed and counted to provide a basis for quality management and production optimization.

Main functions

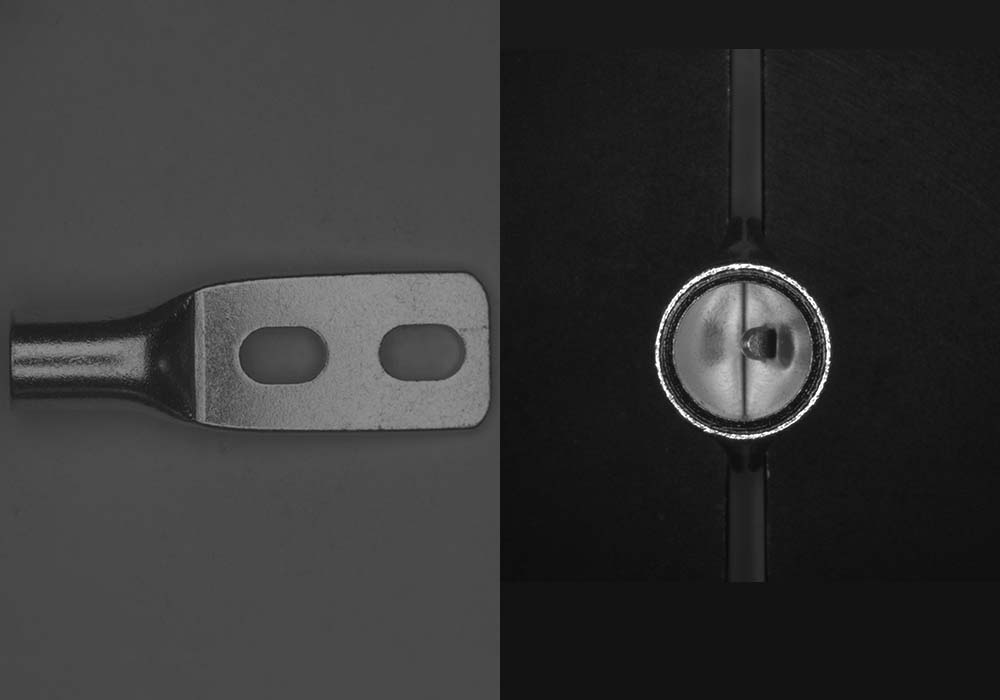

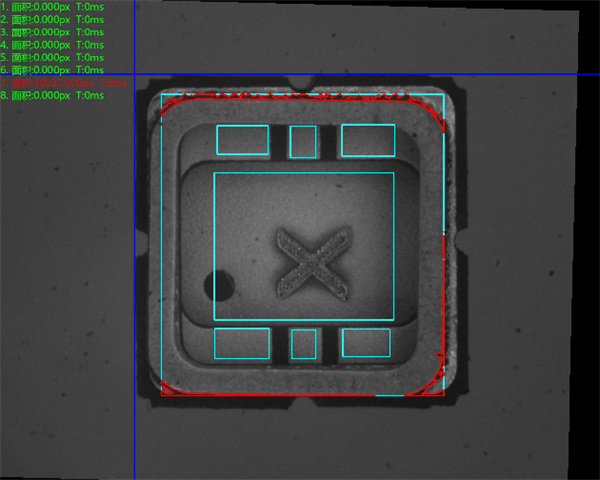

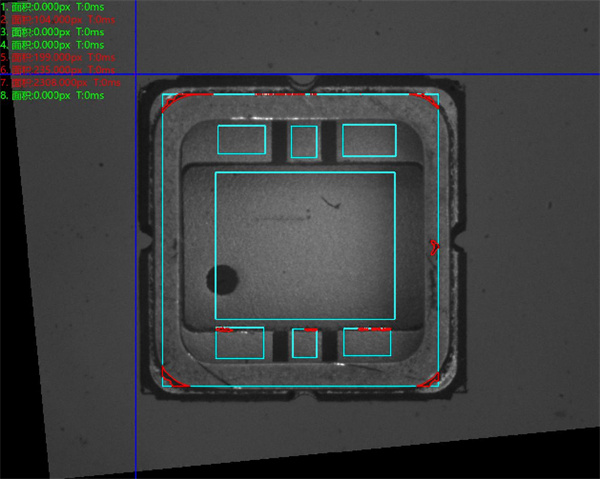

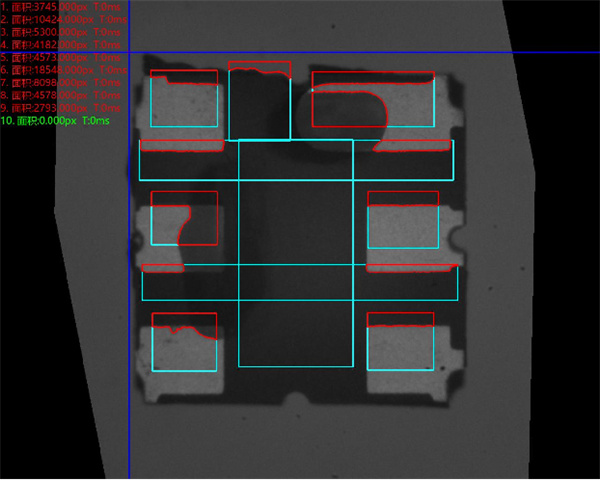

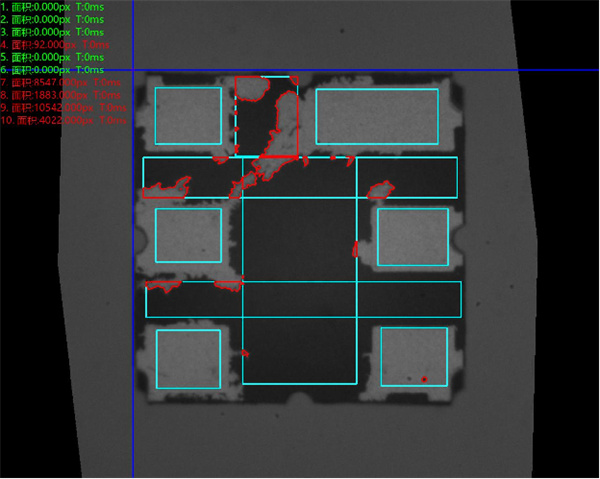

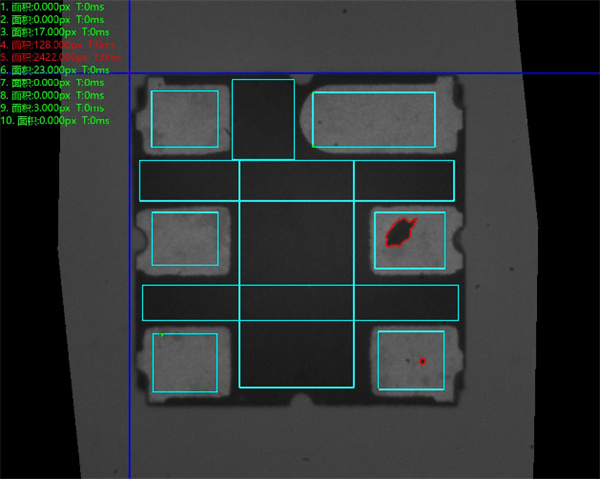

Defect detection: It can detect defects on the surface of ceramic parts, such as bubbles, cracks, spots, bumps, etc.

Color difference detection: Detect color difference problems on the appearance of ceramic parts to ensure consistency of product color.

Surface defect detection: Identify and detect scratches, defects and other problems on the surface of ceramic parts.

Dimension measurement: Measure and check the dimensions of ceramic parts to ensure that the products meet the specifications.

Foreign matter detection: Detect foreign matter on the surface of ceramic parts to ensure product quality.

Detection process

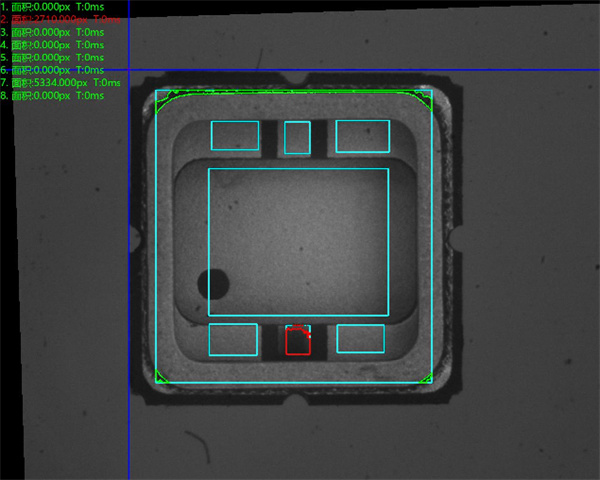

1. Blockage inspection

2. Missing ring

3. Ring diviation

4. Bond finger short length inspection

5. Excess ceramic

6. Excess metal

7. Stain

System installation requirements:

Inspection space for equipment placement: Intsoft Tech’s standard overall inspection equipment for the visual inspection system needs to ensure sufficient space for equipment installation.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA.