Round ceramics are ceramic products with a circular design as the theme. They are usually made of ceramic materials such as porcelain and pottery. They combine artistic beauty and practical functions in design. They are works of art that combine aesthetics and practicality. In the production of ceramic industry, they are often processed into cups, bowls, plates, vases, etc.

However, due to the characteristics of ceramics, various defects are prone to occur, such as edge defects due to collision, abnormal color due to the temperature during firing, dirt, depressions, engraved pattern defects, cracks, etc. Intsoft Tech’s ceramic machine vision inspection system can accurately detect various defects in ceramics and inspect at a speed of 200+ pieces/minute.

Detection machine characteristic

1. High resolution: CCD sensors have high resolution and can capture images with rich detail.

2. High speed: CCD visual inspection equipment can quickly collect and process image data, enabling rapid detection and analysis.

3. Accuracy: Through sophisticated image processing algorithms, accurate detection and measurement of object characteristics can be achieved.

4. Stability: CCD technology is stable and reliable, suitable for long-term stable operation.

Detection machine composition

Visual inspection software: Intsoft customized

Industrial Computer: Intsoft Tech Customized

Display: PHILIPS 19″ LCD display

Industrial camera: Sony Industrial Camera

Camera adjustment servo module: Intsoft Tech customized

Industrial lens: FA high definition optical industrial lens

Light source: customized adaptive optical light source

Inspection platform: professional optical glass stage

Servo motor: Panasonic

Control system: Intsoft Tech customized

PLC Motion Collaboration: Panasonic

Inspection process

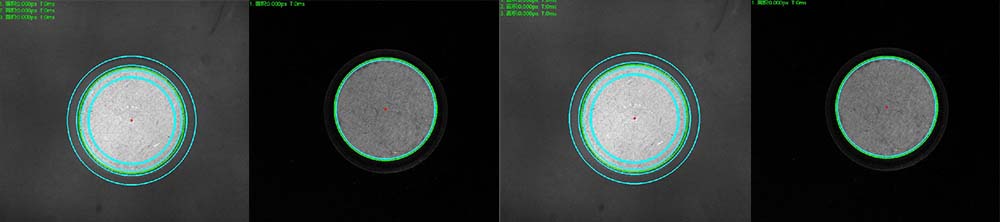

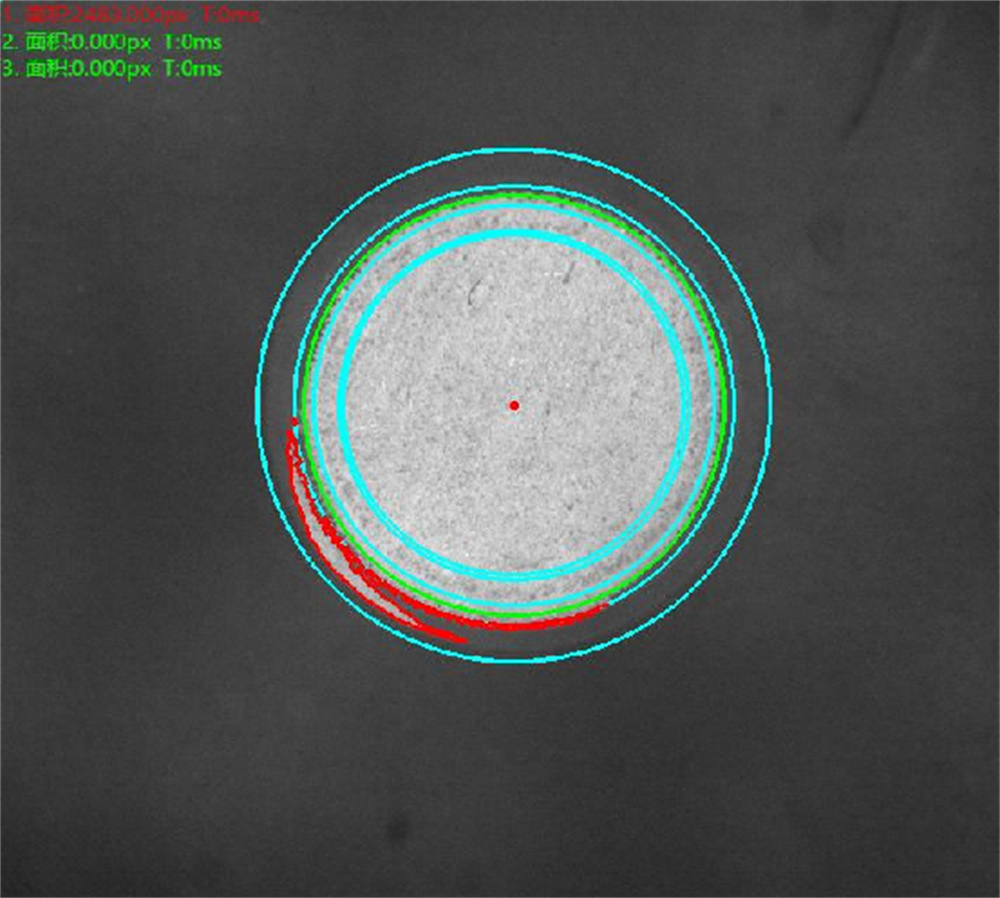

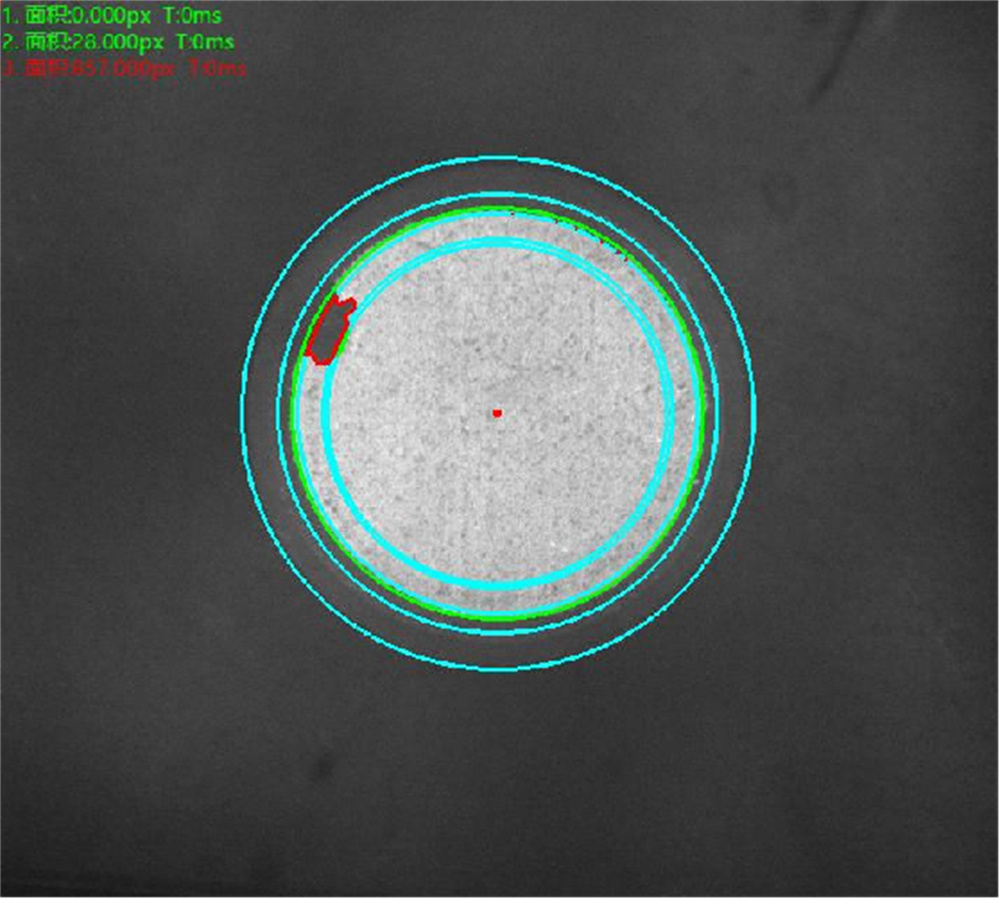

Good product image

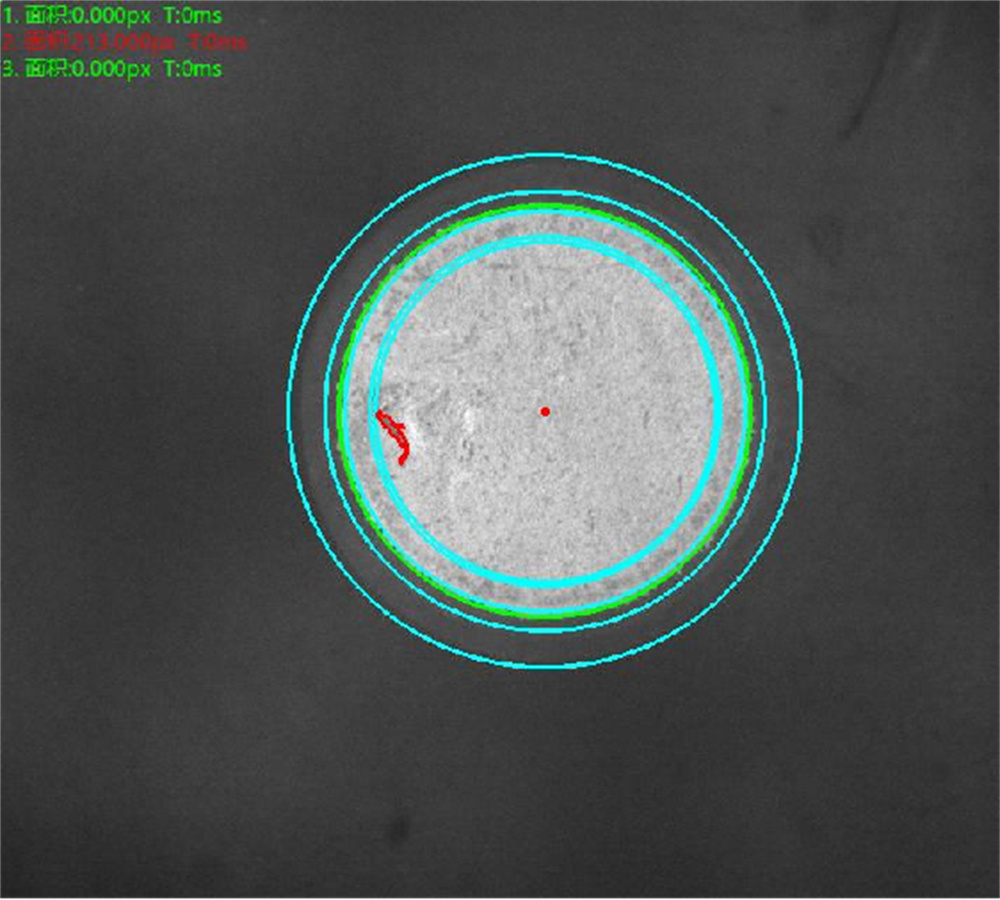

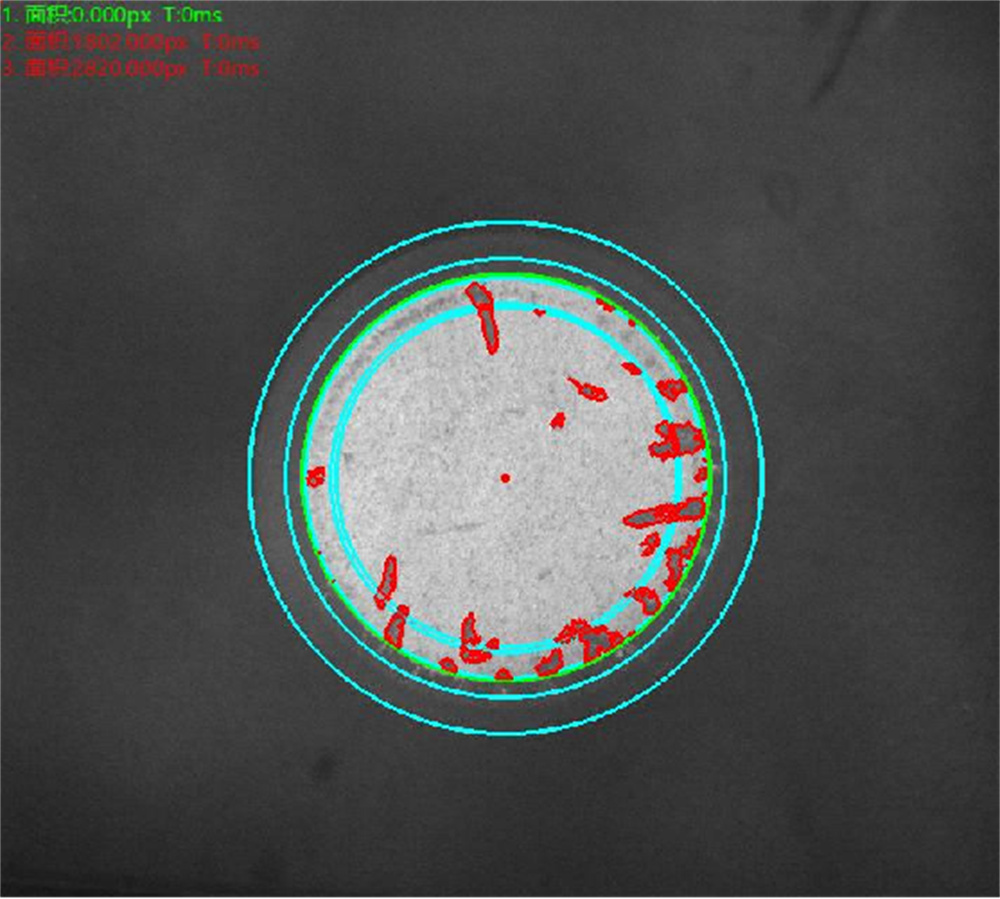

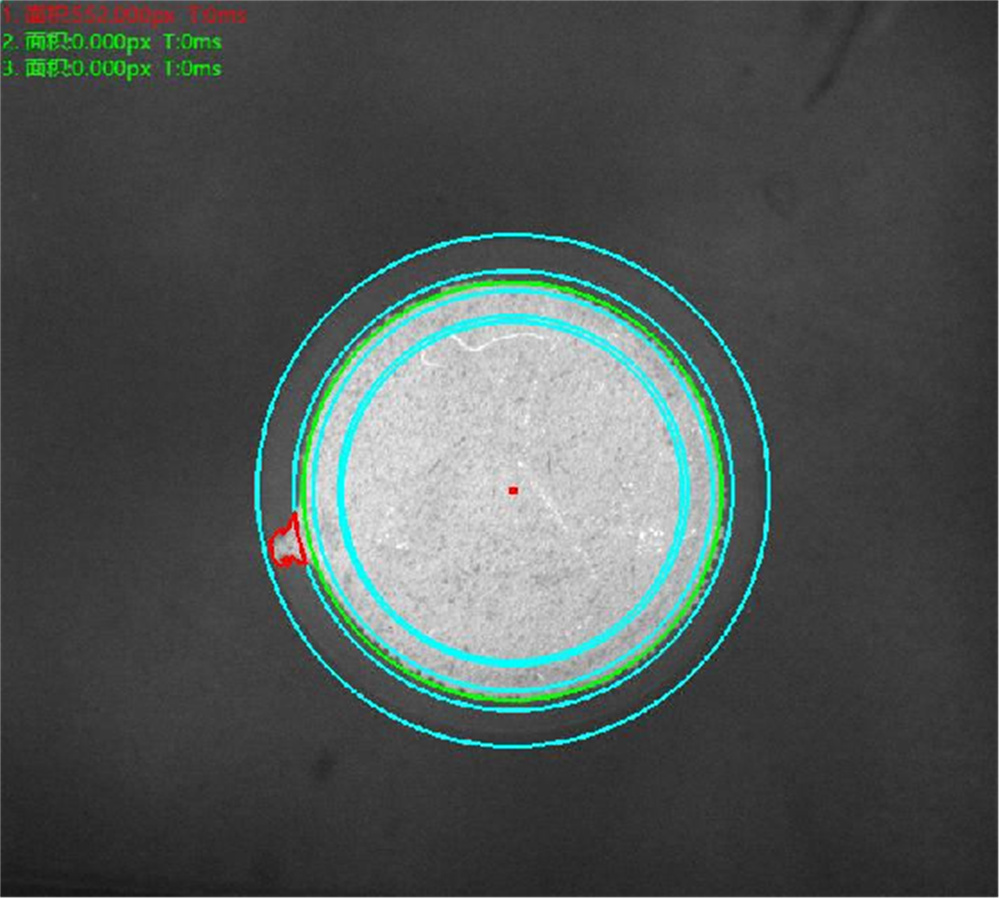

Edge defect image

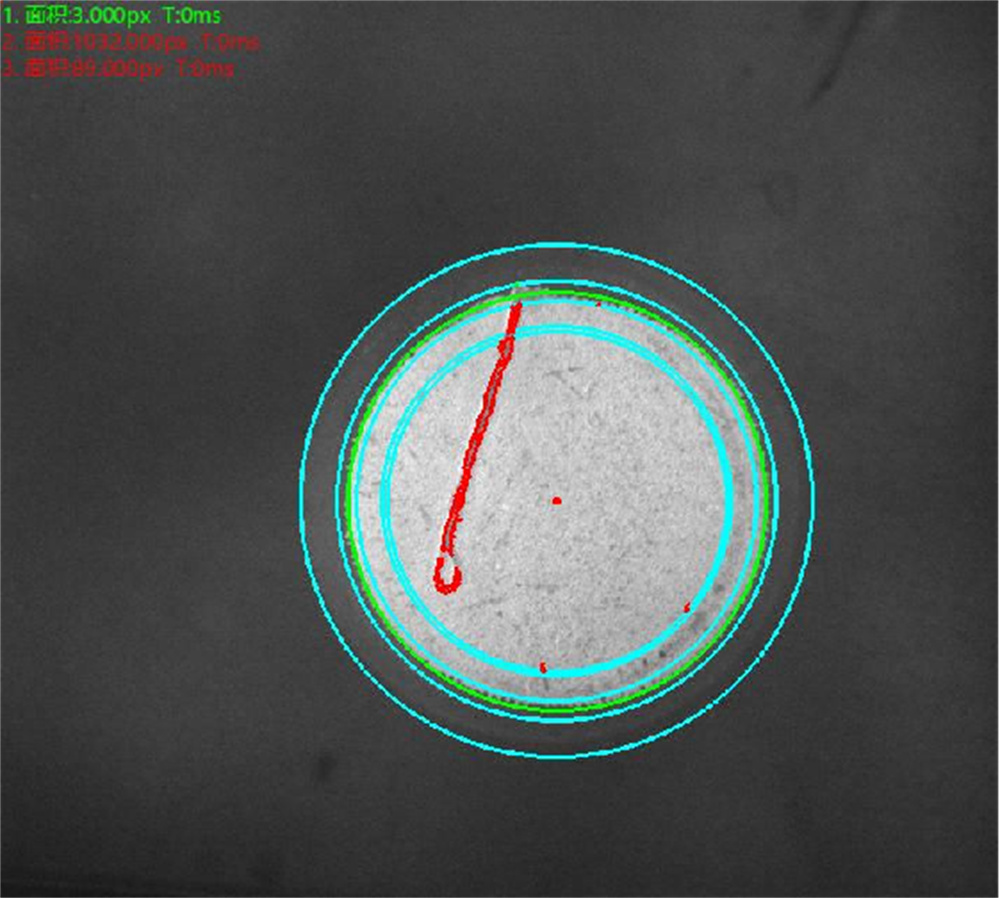

Scratch

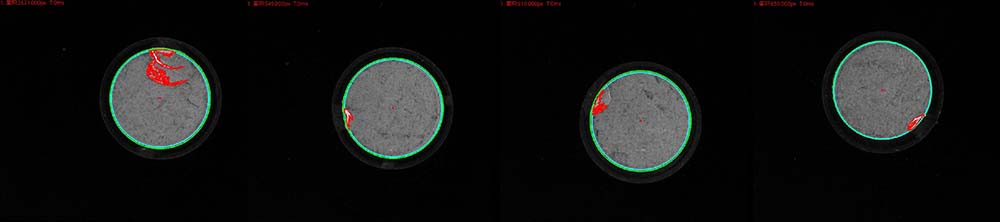

Stain

Defect

Color loss

Color pollution

Pit