Deep learning AI system detects glass surface imperfections and defects

With the increasingly stringent requirements of users for the quality of glass film, more and more manufacturers are focusing on the surface quality of glass.

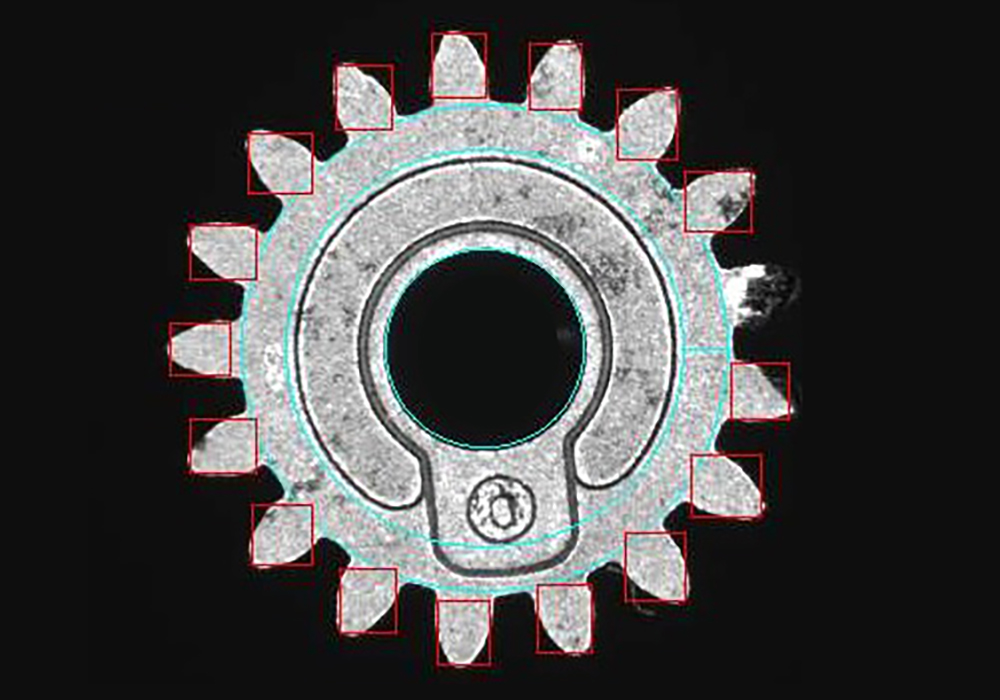

Glass defects, chipping, scratches, creases, texture, poor protective film, light leakage, oil accumulation, orange peel, etching chipping, scratches, pockmarks, black spots, crystal spots, impurities, inclusions, lines, black spots, gel appearance defects for the main defects on the glass surface, very small imperfections will affect the quality of the product.

At present, traditional production-oriented enterprises use the human eye to detect defects, but due to the high cost of manual inspection, easy to fatigue and the human eye can not be detected in the high-speed operation of the production line, so the traditional human eye inspection can not meet the requirements of high-quality production processes.

Intsoft Technology (glass defects deep learning AI inspection system) can be high-speed, accurate online defect detection, and combined with on-site processing online alarms, reports and statistics and product classification processing, to ensure product quality for enterprises to provide effective solutions.

The process of Intsoft Technology deep learning AI detection system for glass defects

Intsoft Technology inspection system is able to realize online high-speed, accurate defect detection, and combined with on-site process on-line alarms, report statistics and product classification processing, for enterprises to ensure product quality to provide effective solutions.

- Function and requirements

| No. | Requirement name | Parameter |

| 1 | Inspection width | MAX 2000mm |

| 2 | Inspection speed | MAX 500m/min |

| 3 | Defect type of inspection | Pocking mark, impurities, inclusions, lines, black spots and other cosmetic defects. |

| 4 | Detection accuracy | MIN 0.05mm |

| 5 | Defect marking | Automatic audible and visual alarms and software marking of defect location, quantity and size |

| 6 | Report Printing | A quality report is generated after each roll of glass is produced. |

| 7 | History Recording | Recording of defects in meters, diameters, lateral position, image information |

| 8 | Classification of defects | Automatic classification of defects according to the imaging characteristics of the different defects. |

| 9 | Mounting position | The exact mounting position is determined on site |

| 10 | Operating position | Installation within the length of the camera’s camera link cable |

| 11 | Detection Requirements | 100% detection within the required detection accuracy |

| 12 | Defect marking | Automatic labeling of defect edges (optional) |

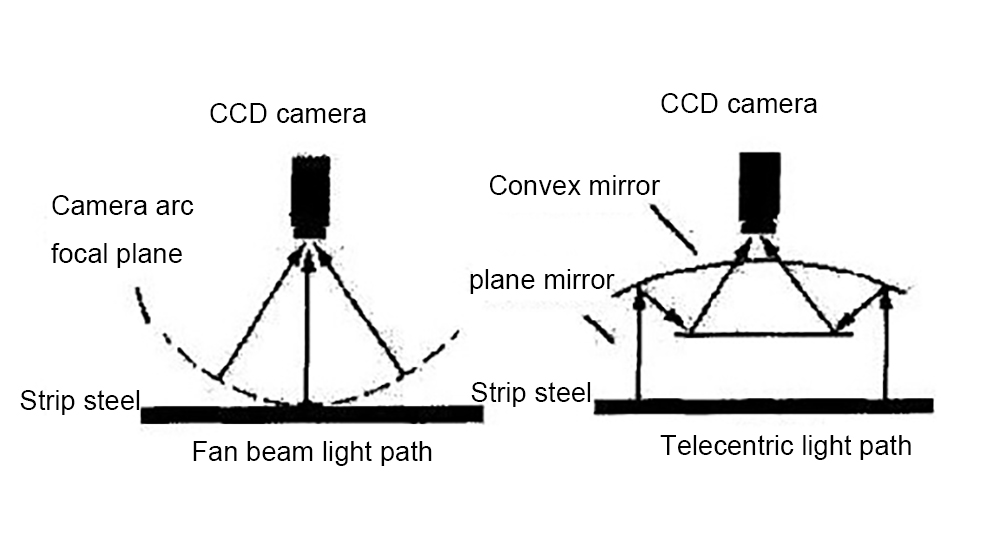

The industrial line array CCD camera is set up above the production line, and at the same time adopts high brightness LED linear spotlight cold light source for backlighting, through the line array CCD camera and high-speed image processing system for real-time online scanning. When defects appear on the surface of the glass, strong light passes through the glass, and at the same time, the CCD captures the surface image through the image processing system to discover and obtain image information of surface defects. The system automatically records the defect image, location and other information, and at the same time through signal control to realize the marking machine on the defect in automatic labeling and positioning.

Line array CCD camera via the encoder connected to the amplitude drive axis triggered to obtain image information of the amplitude. The CCD camera resolution, longitudinal line sweep frequency and other properties to determine the acquisition accuracy of the system, high system accuracy, image data processing large amounts of data after high-speed processing to retain the glass surface defects of the data information (size, diameter, horizontal and vertical position) and control the output of the computer system through the database. The computer system records and manages information such as the specific location, size and image of defects.

- The system detection schematic is shown in Fig below:

- The glass surface defects deep learning AI detection system contains:

- High precision original imported industrial line array CCD camera and optical lens.

- Original imported high brightness industrial line array LED linear cold light source.

- Original imported digital image acquisition and processing system.

- Trigger control input and a set of I/O execution control outputs.

- Automatic alarm and statistical system.

- Industrial system integration software.

- Industrial electrical control cabinet.

- Stands for fixed camera adjustment and other mechanical supports.

- Sound and light alarm system.

- Advantages of Intsoft Technology deep learning AI detection system for glass defects

- 100% online detection of glass surface defects. When defects are found, sound and light alarms can be set according to the system, while the edges of the product width can be automatically marked according to the needs (optional), prompting timely repair to avoid a large number of defective products;

- Detailed product defect information statistics. When the defect is detected, the system will automatically count the current defect image, area, location, size and other information, while each volume of the product has a complete image of the defect, location distribution and quantity statistics and other information can be printed through the printer.

- Deep learning AI detection system for glass surface defects, high precision, the program can be 100% detected above the set accuracy of hole defects to meet customer’s constantly improving product quality requirements.

- Software database management function, can be produced for each roll of material for accurate quality statistics, detailed defect record (size and location) and statistics for production process and equipment status adjustment , providing a convenient offline analysis, for subsequent slitting and quality management, can effectively ensure product quality;

- Glass surface defects deep learning AI detection linkage system. When the system detects defects for sound and light alarms, can also be added to the system other I / O output chain.

- Software features:

- Real-time defect location distribution map display.

- Real-time defect image and specific information display.

- Automated generation of product batch numbers at the same time you can manually modify the product batch number during the production process.

- According to the product lot number to establish a perfect history database query, access.

- History records are automatically generated corresponding to the batch number of defects in the location of the distribution map to facilitate post-processing.

- Statistical generation and printing of information reports.

- Real-time defective picture interception display.

- Long time and large capacity history record storage.

- Remote technical service.

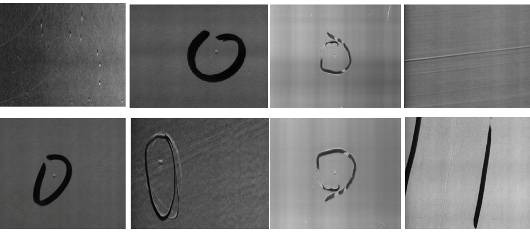

Before the deep learning AI inspection system for glass surface defects performs the inspection, it will collect the drawings of various defects, analyze the characteristics (e.g., size, shape, area, etc.) of each defect, and create a defect database. This is shown in the figure below: