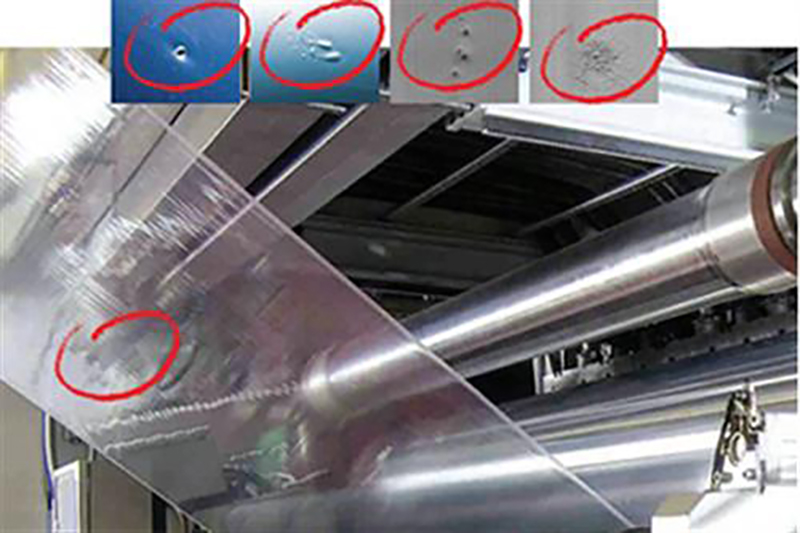

Detect minor defects that may indicate a cap seal failure

Glass vials are plugged with a rubber stopper after filling. An aluminum cap is then wrapped around the top edge of the vial. The cap may vary in color depending on the product. Vial seal integrity is important because improperly sealed vials can lead to leaks or product contamination, which poses a serious risk of recalls. Machine vision automated vial inspection ensures that only properly sealed vials are allowed to pass the qualification.

After an initial inspection to confirm that the stopper has no bulging, proper alignment and fit of the cap and stopper, presence of debris or contaminants, damage or deformation of the cap or stopper, adequate seal and tamper-evident features etc,. a cap is wrapped around the neck of the vial.

Medical vial inspection includes items detected for missing caps, cap defects, crakes and whether the cap color matches the product. Faults that may appear to be minor cosmetic problems, such as scratches or small holes, can also indicate seal problems and contamination.

Cracks in the base or edges of vials and ampoules, as well as other defects such as scratches, bubbles, black spots and inclusions, can lead to contamination of the contents or compromise sterility. Vial and ampoule inspection must identify these defects before the product reaches the customer to protect the safety of drug users. Pharmaceutical glass may also have minor defects, such as scratches, that do not affect functionality.