Syringe Needle Inspection

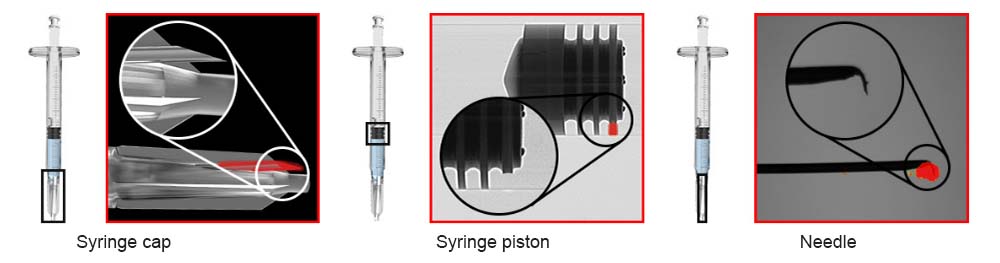

Detection of defects in precision beveled needle tips

Hypodermic needles or cannula are made by thinning and hardening the metal after it enters a die extruded tube. In order to penetrate the skin, the needle tip must be beveled, which is usually processed multiple times at different angles to form a needle tip suitable for the intended purpose. The bevel may be unevenly ground or leave burrs, barbs, and other irregularities that affect function or even endanger patients.

Because multiple die drawings are required to form the appropriate needle gauge, there may be differences in the inner or outer diameter. In order to protect patient safety and ensure correct vaccination, it is very important to check hypodermic needles for defects.

Function

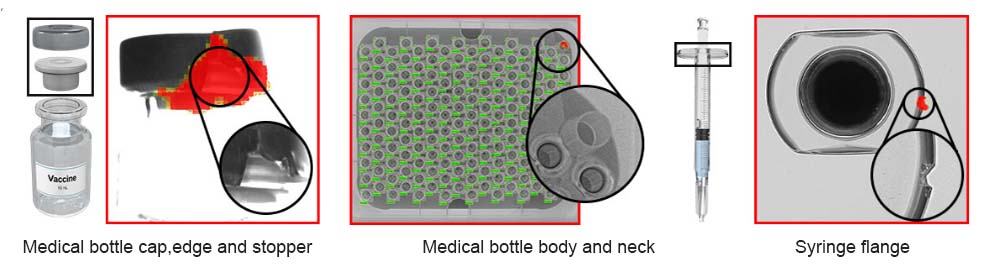

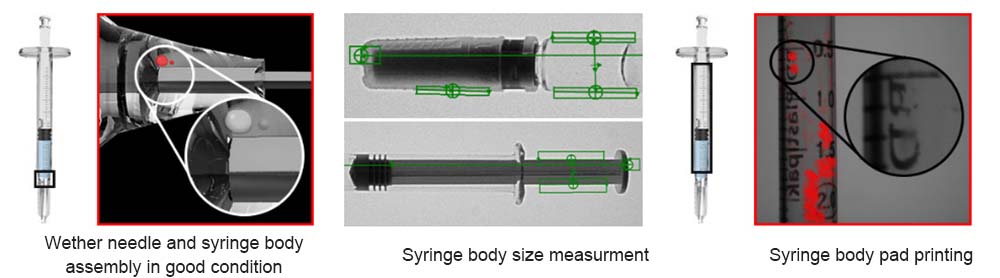

1. Machine vision inspection for syringe needle caps, plungers and needles.

2. Needle and syringe assembly verification inspection.

3. Pre-filled syringe size inspection, pre-filled syringe pad printing inspection.

Detect various minor defects in beveled needle tips

Defect detection equipment is completed by detecting high magnification sample images of the bevel range. Any changes in light will show the structure of the needle surface, high reflectivity indicates smoothness, and dullness indicates potential defects. The same procedure can also be used for dimensional inspection of needles, confirming the inner and outer diameters of the needle tip.