In traditional visual defect detection, some fine folds, scratches, picking pictures with very low contrast is more difficult to deal with. So, what to do?

The following share of lithium battery defects fold AI detection system case, in the actual production of lithium batteries, in order to prevent battery leakage, resulting in safety accidents, lithium battery detection should be done:

- Detect if the battery is edge banding in good condition.

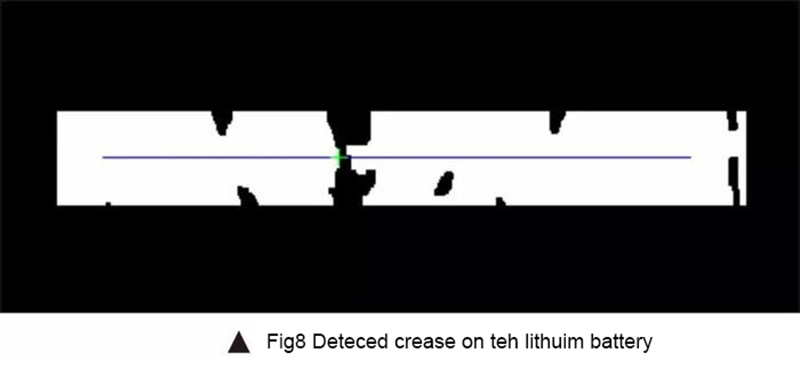

- Detect if the distance from the sealing edge to the battery edge there is a crease.

Detection overview

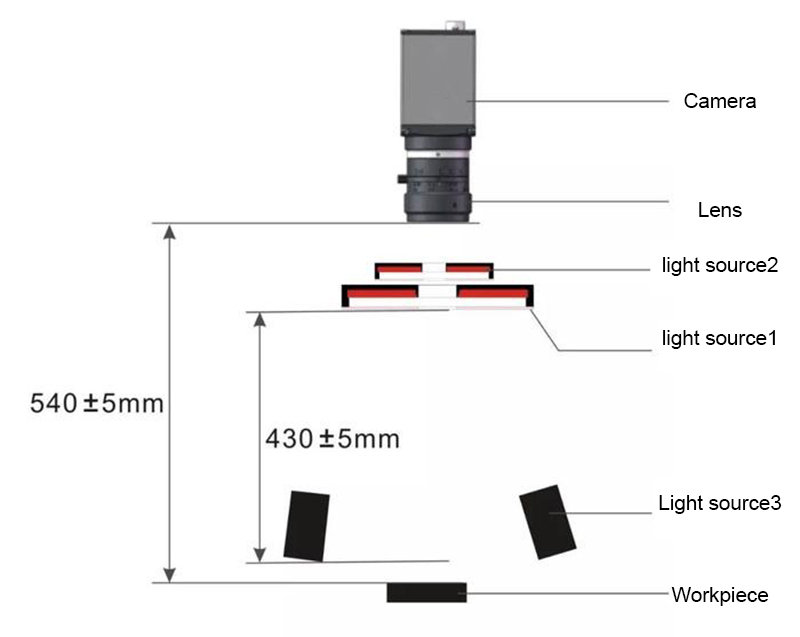

There are workpieces in silver and black colors, silver workpieces are more reflective, the uniformity of the light source is required to be better, easy to distinguish from the background in the detection of folds.

AI Visual Inspection Hardware System

Obtain images

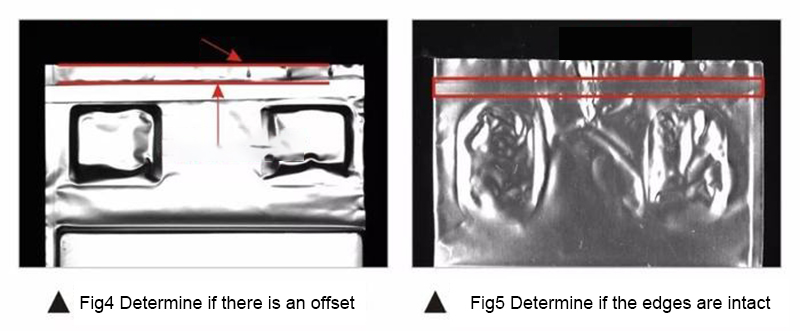

- Identify the upper edge of the battery sealing edge and the upper edge of the battery, and judge whether the sealing edge is offset by measuring the spacing between the two (as shown in Figure 4.

- Identify the folds on the battery sealing edge to determine whether the sealing edge is intact (as shown in Figure 5).

Detecting the distance of sealing edge

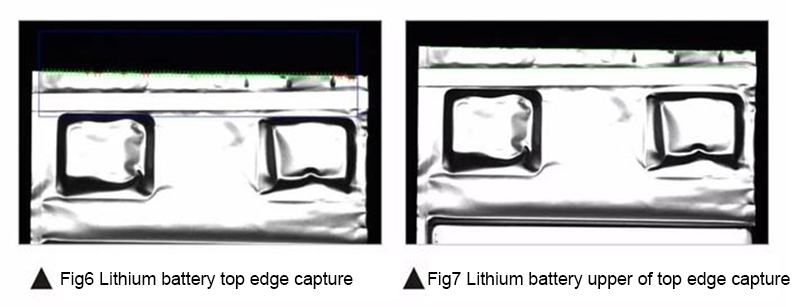

When detecting the edge of lithium battery sealing, it is affected by various folds with uneven local reflective effect, so the ordinary software method of detecting the distance is easily affected by the flatness and neatness of the background. Through Intsoft Technology (deep learning AI vision inspection) software, various image algorithms can be superimposed to filter out interference factors, retaining only the necessary part. The detection results are shown in the figure:

Fold Detection

For most battery defect detection uses a traditional machine vision inspection system, in which how to highlight defects and extract useful information is the traditional vision processing difficulties. But these challenges, in front of Intsoft Technology’s next generation of deep learning AI inspection systems, can be easily detected.