The most common seal in life is the sealing ring, also called oil seal, which plays the role of isolating oil and preventing oil from overflowing or passing through. It is widely used in various industries such as construction, agriculture, industry and technology. Therefore, there are many manufacturers of sealing rings, especially in recent years. Large-scale production will result in defective products, and the defects of traditional sealing rings are mainly detected by manual detection. This detection method requires high labor intensive, easy to fatigue, introduces human errors and poor detection stability. Machine vision can solve this problem very well.

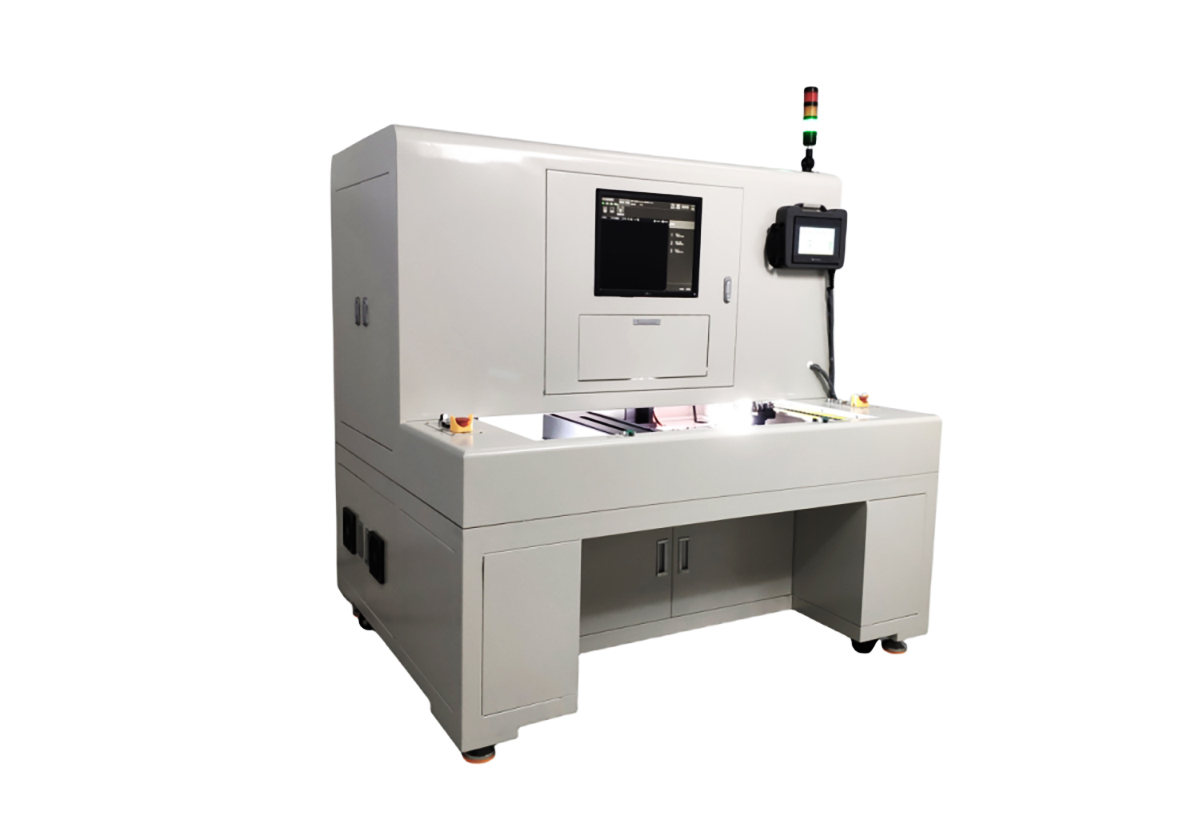

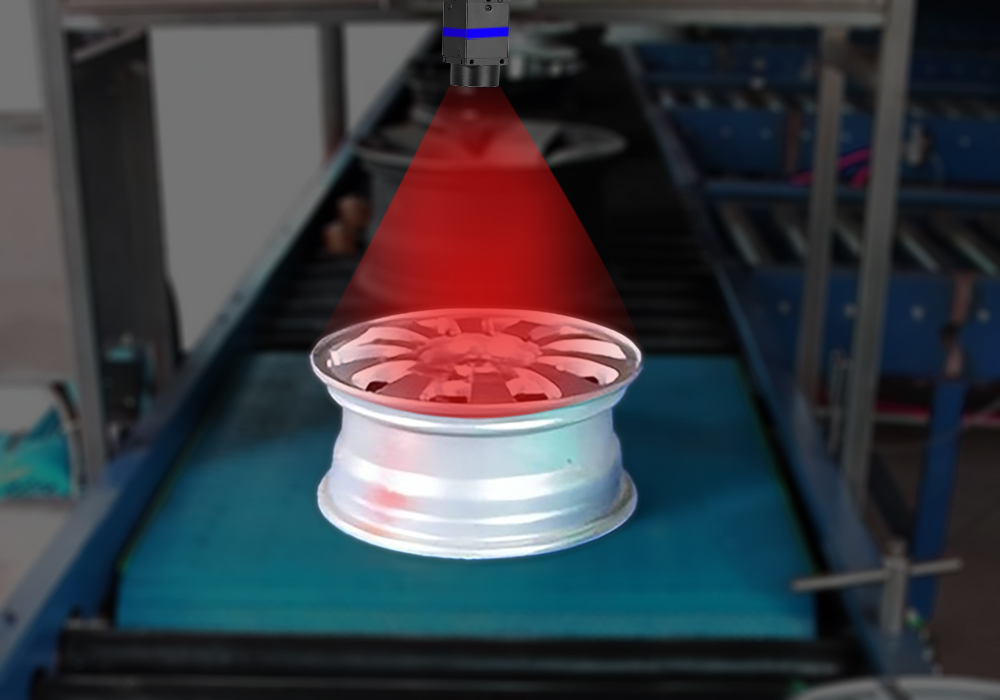

The vision detection equipment for sealing rings uses high-definition industrial cameras, customized special light sources, and provides a professional visual inspection environment. With the automatic rotation of the workpiece, it can easily present the defects of the gear end face, inner wall of the tooth, top of the tooth, bottom of the tooth and other parts clearly in the image.

Detection process:

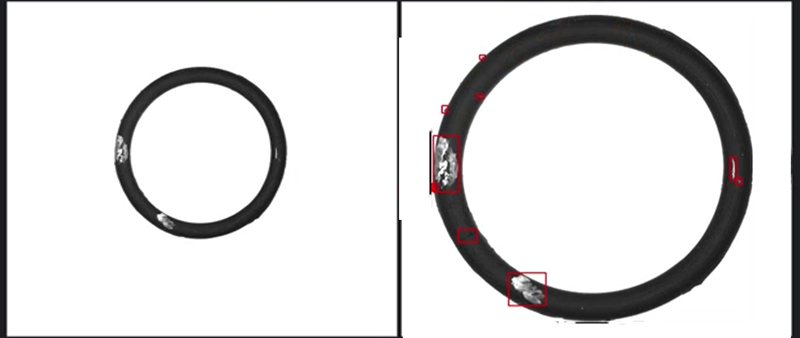

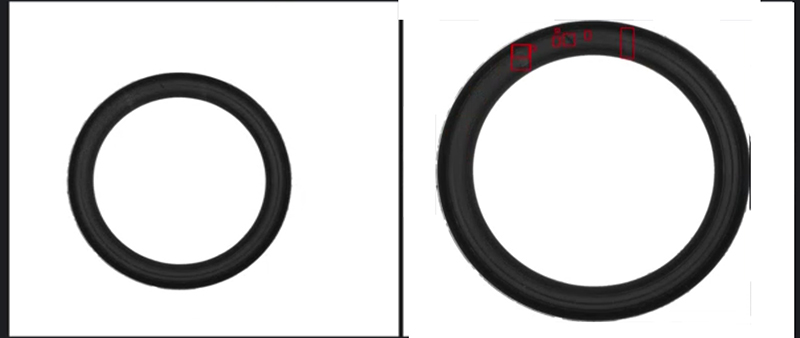

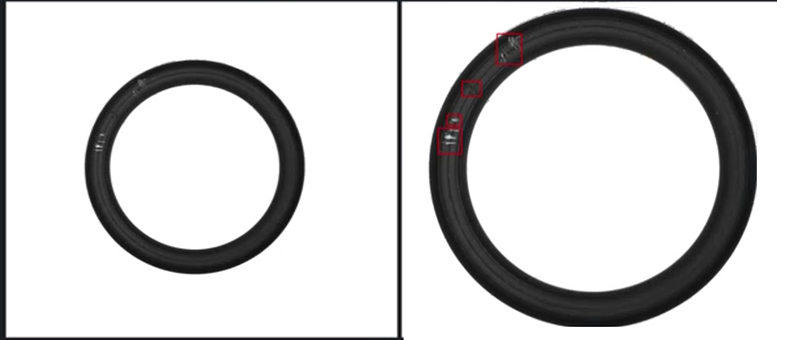

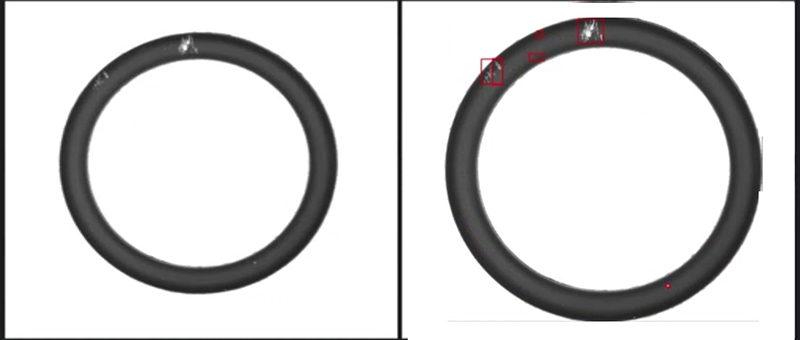

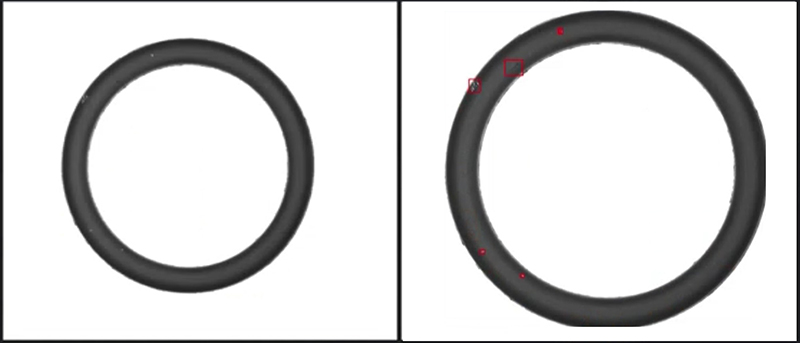

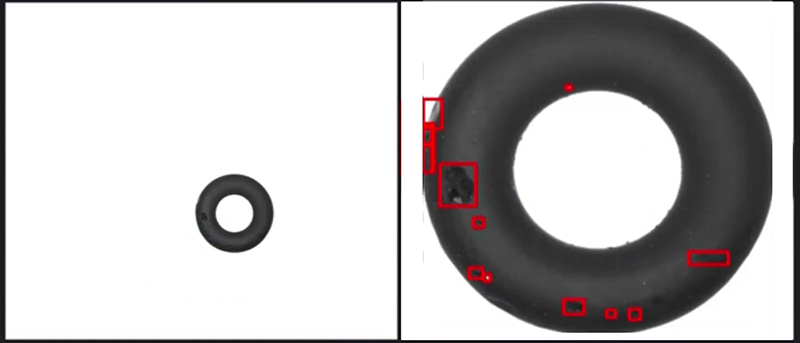

Surface defect detection of sealing rings

The left side is the original image acquisition, and the right side is the corresponding visual inspection processing result.

Sealing Ring Defect Types

The most common defects that can be detected using machine vision include:

Surface imperfections: Scratches, dents, pits, inclusions, discoloration

Geometric deviations: Incorrect diameter, thickness, roundness, flatness

Material defects: Voids, cracks, foreign particles

These defects can occur during the manufacturing process, such as molding, cutting, or surface finishing operations.

Machine Vision Inspection System

A typical machine vision system for sealing ring inspection consists of the following key components:

Lighting system: Provides consistent, high-intensity illumination to enhance feature visibility.

Camera(s): High-resolution, industrial-grade cameras capture detailed images of the sealing rings.

Part handling: Precision mechanisms to accurately position and orient the sealing rings for image capture.

Image processing software: Advanced algorithms analyze images to detect and classify defects.

PLC/control integration: Allows the vision system to communicate with production line controls.