Some minor scratches, blemishes, defects, and even traces that are not visible to the human eye under normal circumstances are difficult for traditional vision to capture a good image. Then you should learn about Intsoft Technology’s deep learning AI intelligent inspection system.

Smaller, more subtle, more complex environments, defects and flaws have nothing to hide!

Intsoft Technology deep learning AI visual inspection system, through the training of user sample data to customize and optimize the model, so as to adapt to the user’s actual use of the scene.

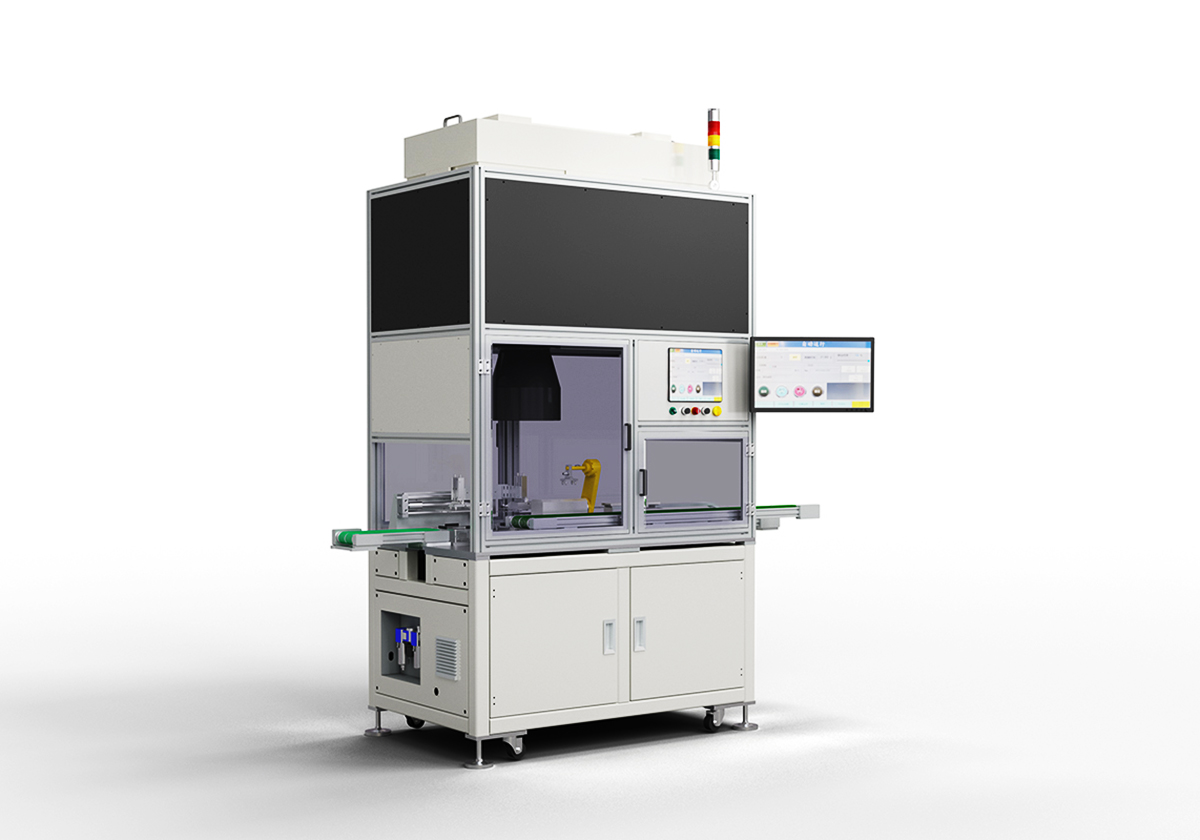

When the algorithmic model is integrated with the production line or inspection and acquisition equipment in the production environment, computer vision can replace manual inspection work for quality, safety, integrity, etc. in the production process.

Based on the uninterrupted and fatigue-free nature of computer vision, it can provide much higher inspection efficiency and accuracy than manual labor, and work with manufacturers and production equipment suppliers to reduce industrial production costs and increase production capacity.

AI visual inspection product features

1. Break the closed environment of the previous visual inspection, without programming. According to the software, “foolproof” prompts can be completed sample learning and execution of the recognition task, easy to start. Customers can teach AI-Intsoft to complete complex identification tasks according to their needs.

2. Accurate localization and classification, with an accuracy rate of better than 99%, AI-Intsoft can locate the specified position in real time at the sub-metre level, and distinguish up to 1,000 different parts at the same time through intelligent deep learning recognition.

3. AI-Intsoft has a wide range of applications. In the field of 3C manufacturing, it can be applied to the inspection problems of components such as cell phone cases, cell phone accessories, circuit boards, screens, electronic materials, etc. It can also be widely used in the fields of hardware, food, packaging, and automotive.

4. AI-Intsoft system compatibility is very strong. It can run on Win7/10 and above platforms alone, and only requires additional NVIDIA solo display support configuration. With Intsoft Technology’s exclusive machine vision accessories, products can be integrated into a complete machine vision system to address more customer needs.

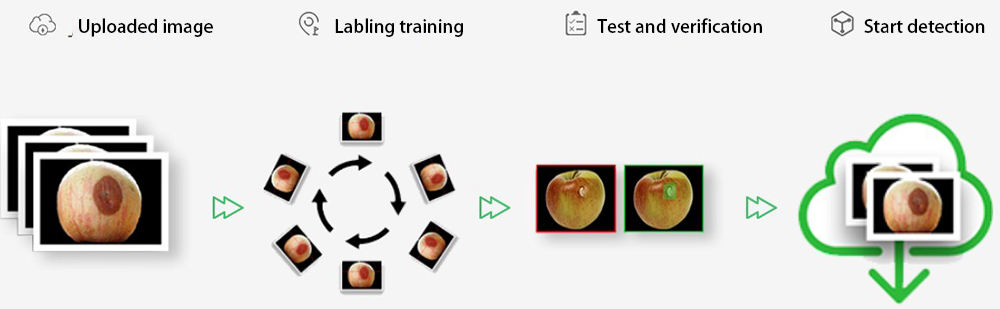

Defect detection process

AI visual inspection function features

Intelligent labeling assistance

Sample labelling not only consumes a lot of labor costs , but the quality of labelling greatly affects the training results. Visual intelligence products instantly train the model with a small number of manually labeled samples, automatically label samples by model prediction, and recommend samples that require manual correction to the labeler, so that labeling work can be completed quickly and accurately through iterative training.

Distributed training

Training and optimizing deep learning-based industrial vision intelligence algorithms requires a large amount of data (not only the sample data provided by you, but also the benchmark training set provided by AliCloud), and the speed of model updates and iteration in industrial scenarios has a direct impact on production line efficiency. We use a distributed training framework to greatly reduce the time required for model optimization.

Intelligent Sample Evaluation

In industrial scenarios, the distribution of annotations on samples is often very uneven, which affects training results and model performance. Visual Intelligence products maximize the value of samples around training objectives through intelligent sample evaluation, the number of samples per label, and intelligent automatic splitting of training and validation sets.

Multi-Dimensional Model Evaluation

Provides rich metrics to facilitate your quantitative assessment of overall model performance and performance on a particular label. At the same time, the prediction results are compared with the original labeling on the samples to provide a visual display of the training effect and model capability.