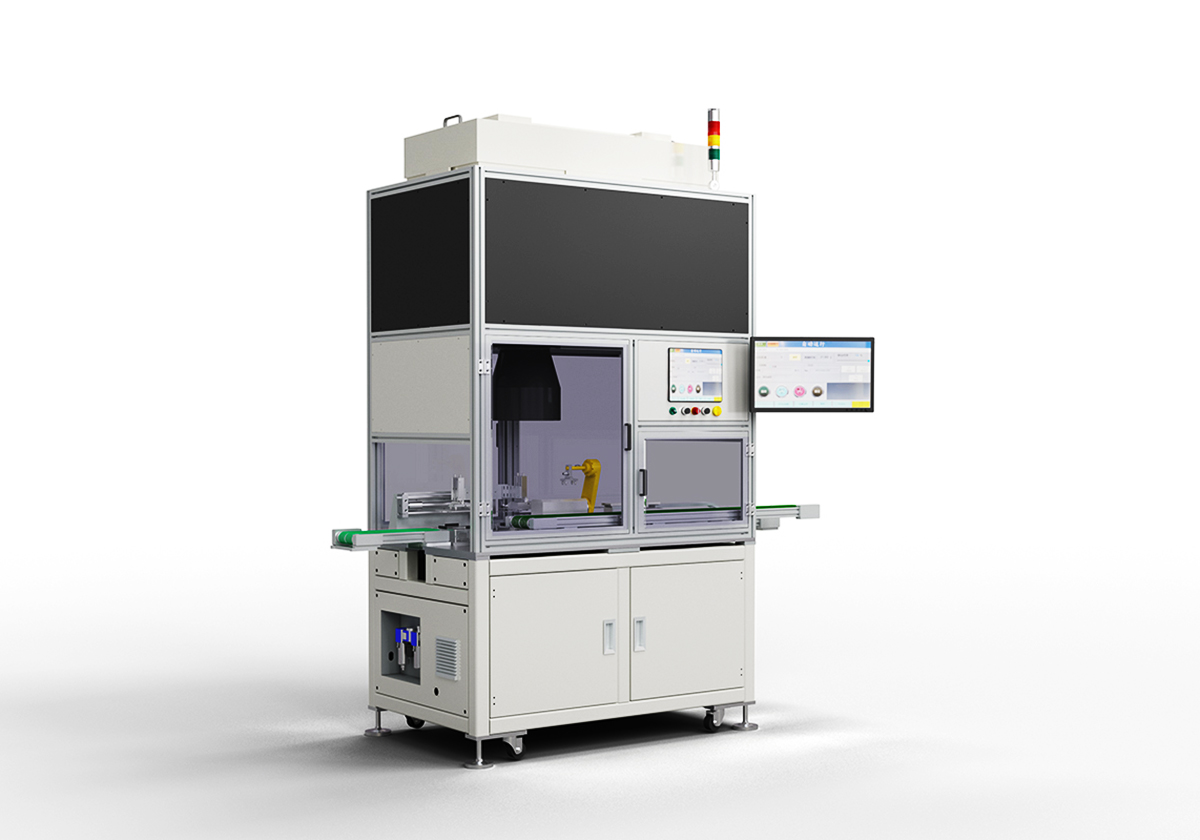

Working Principle

This machine is installed at the end of the production line. Its conveyor belt is used to receive products from the production line and then transport them to the vision inspection area. After a machine vision inspection system, it automatically sorts the good and defective products into two containers.

Function

The advanced screen inspection machine is a specialized device designed to thoroughly examine the surface of electronic display screens, such as Apple watches, cell phones, sports bracelets, etc. small screen electronics, identifying any problems or anomalies that could affect the visual quality and functionality of the final product from the appearance. It also has comprehensive data logging and continuous improvement. The advanced screen inspection machine not only performs inspection and sorting – it also serves as a valuable data hub, recording comprehensive information about the process. This includes details about detected defects, machine performance, and a myriad of other metrics. Manufacturers can use this data to gain valuable insights, identify areas for improvement, and continuously refine their production processes.

Parameter

| Item | Specification |

| Size | H 2500* W 1200* L800 |

| Weight | 500KG |

| Function | Screen inspection machine for electronics |

| Working condition | Volt 220 / Power 3KW |

| Construction | Industrial Camera, Light source, Industrial PC, Conveyor system, Machine body framwork |

| Inspection speed | About 5s/Pcs |

By integrating this advanced machine into the production line, electronics manufacturers can achieve a level of quality control that was once unimaginable. The machine’s lightning-fast inspection speed, combined with its accurate defect detection and automated sorting capabilities, ensures that only the highest quality products make it to the final stage of the manufacturing process.