The syringe filling station of the production line is a core link in the syringe production line, which is specially used to accurately and efficiently fill the material into the syringe. Whether the cap is pressed in place after filling and capping, whether the liquid medicine is filled in sufficient quantity, whether the syringe is sealed intact, and whether the dosage is correct all determine the quality and safety of the medicine. If defective products cannot be detected in time and enter the market, it will at least cause complaints, bring negative impact to the enterprise, and even cause medical accidents and bring significant losses to society.

However, in the actual production process, there are often problems such as fast production speed, different product specifications, different product surface materials, and different specifications and processes for injecting liquids into products. These problems lead to different inspection standards, which brings some difficulties to machine vision inspection.

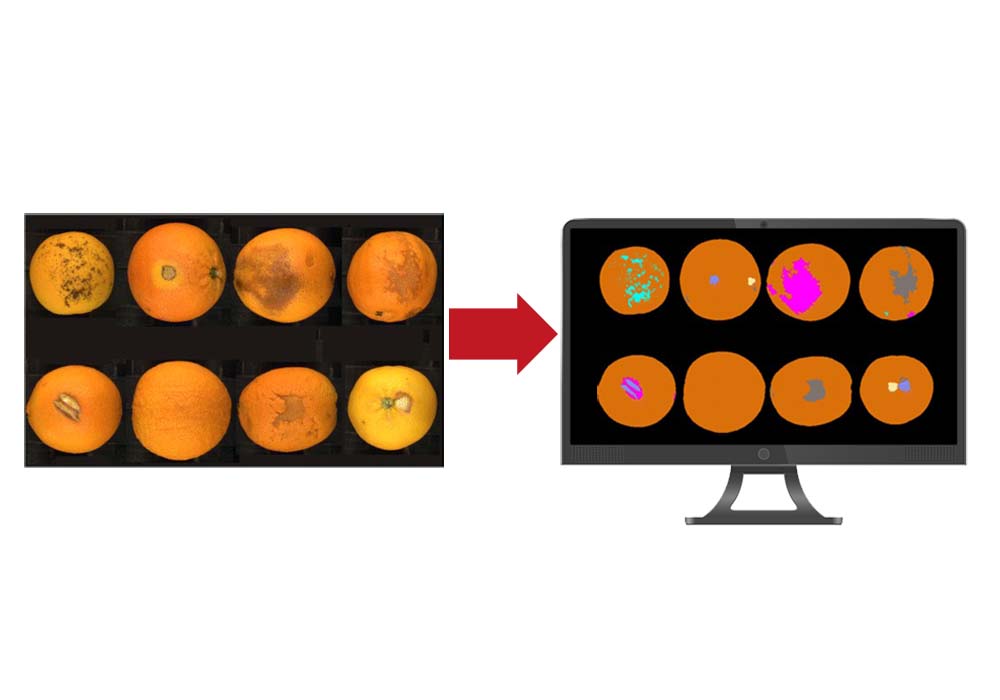

In general, syringe filling inspection needs to meet three requirements:

1. Check if the liquid level of the syringe is within the required range

2. Check if the syringe stopper is present

3. Check if the cap is tightly closed

In response to the above requirements, Intsoft Tech’s intelligent manufacturing technology team, based on the company’s comprehensive machine vision hardware products and self-developed, powerful general intelligent vision development platform, broke through the traditional manual visual inspection and tailored a complete set of multi-functional visual inspection solutions for syringe filling stations for customers.

The Intsoft team carried out an accurate analysis of the technical data of the inspection stations and designed the optimal configuration solution, which can achieve the simultaneous inspection of 6 products, greatly shorten the inspection time, and further improve the work efficiency.

In order to solve the detection difficulties caused by multiple product specifications and different processes, Intsoft Tech team adopted unique feature positioning and detection tools to effectively shield interference items, thus quickly locating the syringe position, liquid level edge, and tube body edge. Combined with powerful computing, data can be quickly processed and classified, and defective products on the syringe filling line can be easily and accurately eliminated.

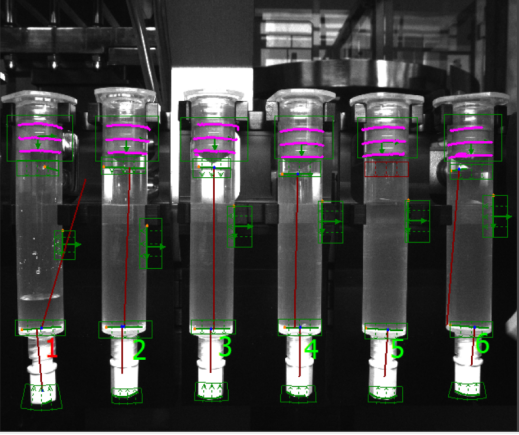

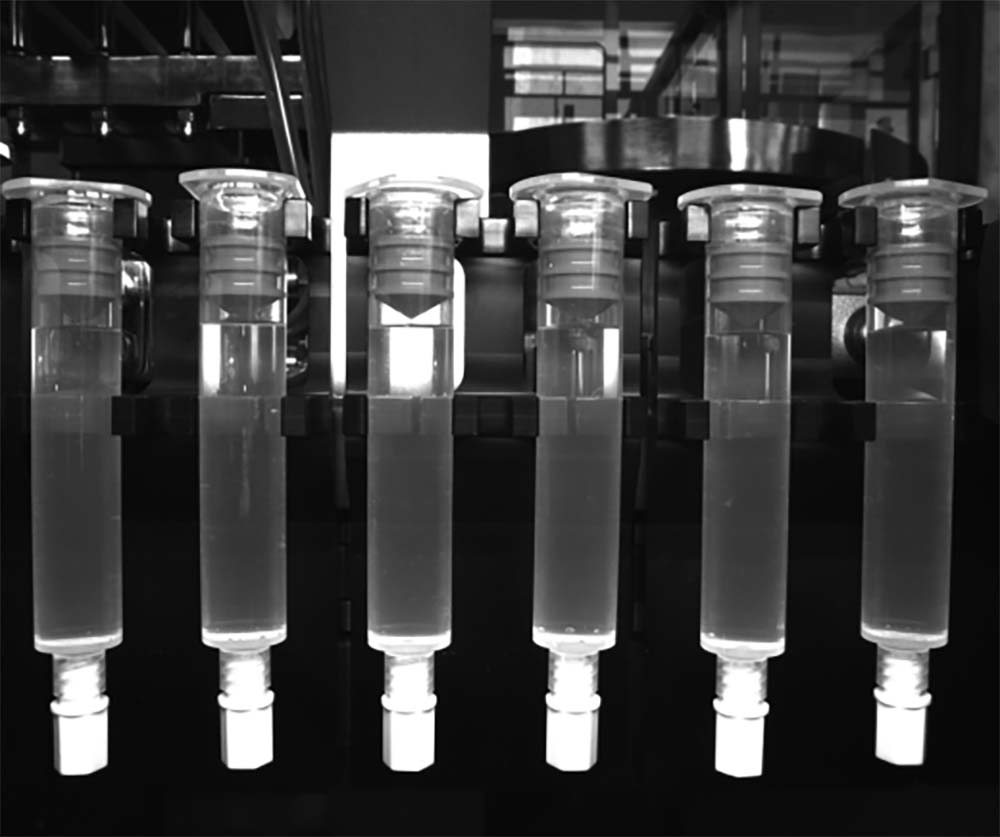

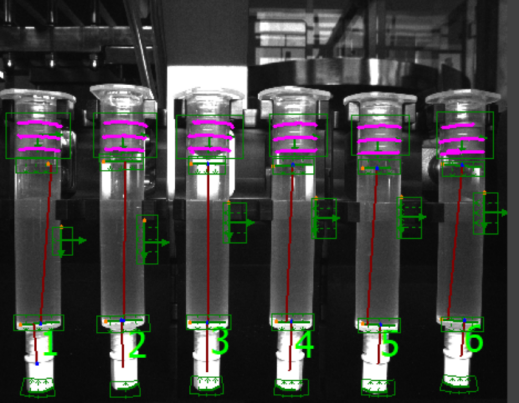

Following are images of syringe for detection

Side detection original image:

Side detection good product image: OK —

Side detection defective product image: NG cause of defect: Wrong liquid level