In the previous two years, when the epidemic was in full swing, the importance of the appearance of medical masks was even more emphasized. As important personal protective equipment, the appearance quality of masks directly affects the protective effect and experience. Timely and accurate appearance detection can ensure that each mask meets the requirements of size, material, marking, and other key indicators to maximize the safety of use. During the production process, it is necessary to screen and eliminate defective masks such as contaminated, broken, uneven color, deformed, etc. through machine vision inspection. Especially for key user groups such as health care workers, qualified quality masks with good appearance not only reduce the risk of infection, but also enhance comfort and confidence in their use, ensure the mask provide better protection. Appearance inspection of medical masks has become an indispensable quality control measure for surgical mask manufacturers, playing a crucial role in ensuring product quality, improving user experience and controlling production costs.

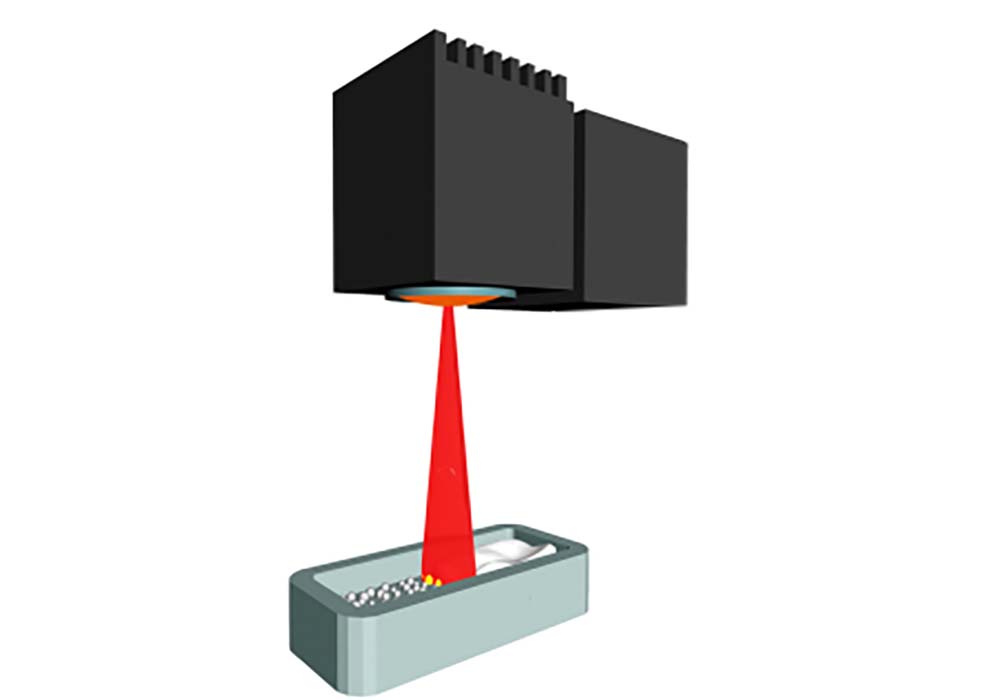

Intsoft Tech face mask detection solution as shared below

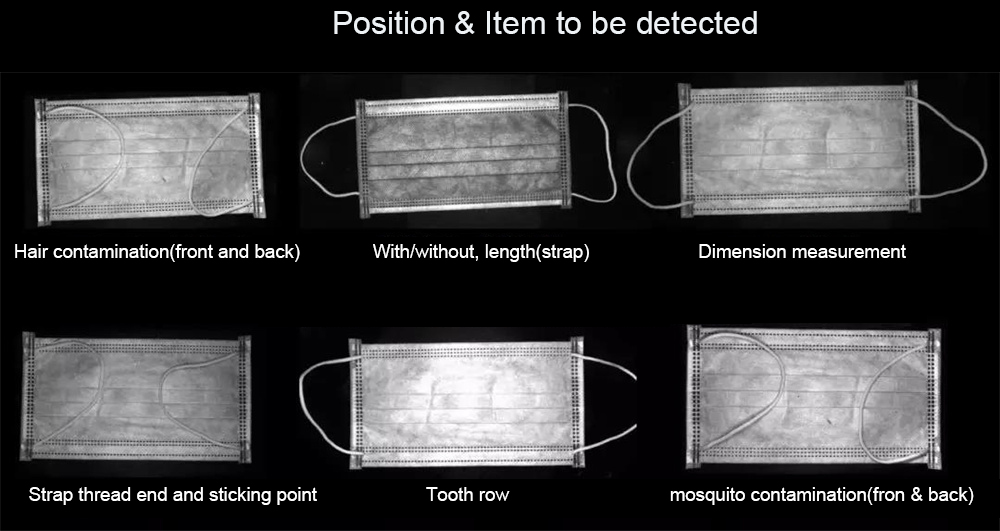

Detection Items

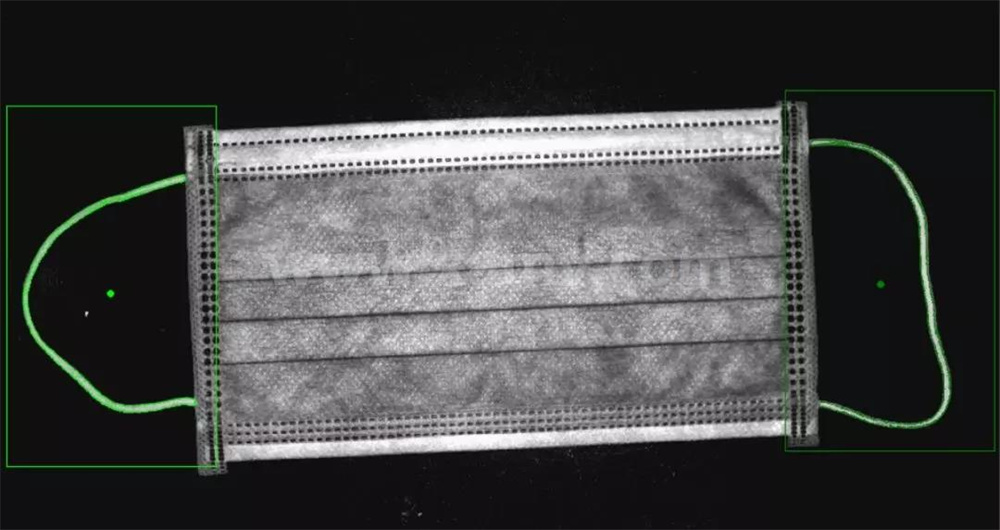

Detection of dirt and mosquito contamination on the front and back of the mask, detection of hair on the front and back of the mask, detection of the length of the ear strap, measurement of the size of the mask, detection of the sticking point of the ear strap wire, detection of the anchoring points row of the mask, etc. And can be seamlessly connected with mask production equipment signals, defective products quickly rejected outside.

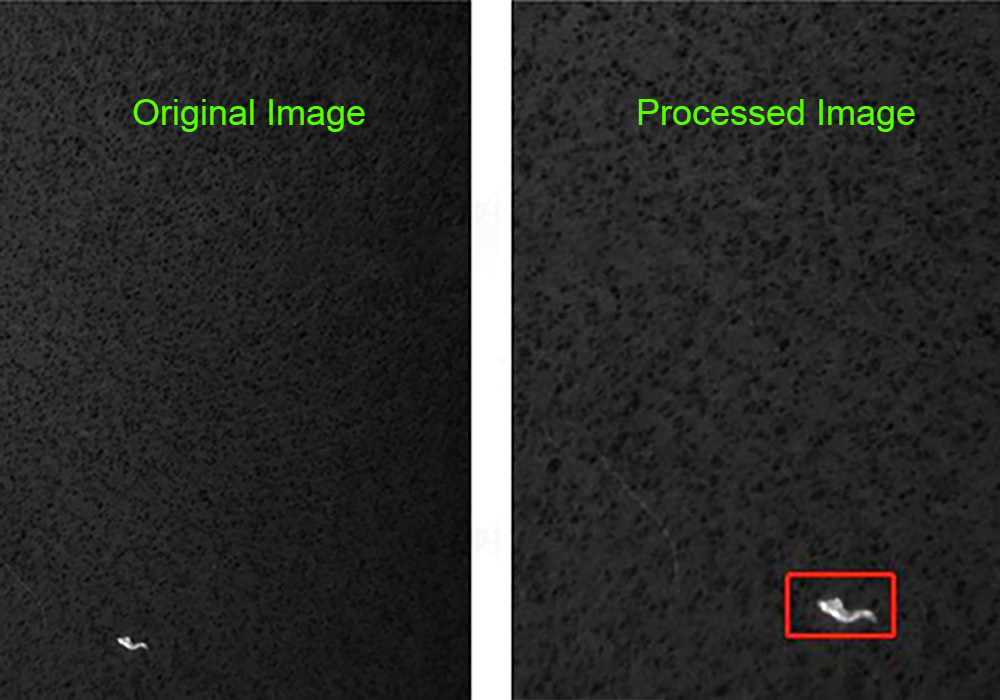

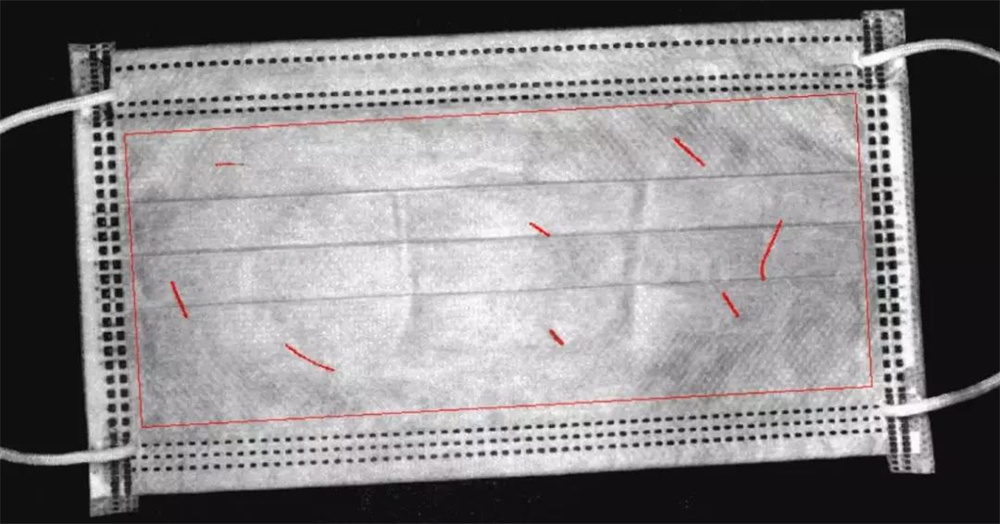

Front and back side of mask hair contamination detection

During the mask production process, flocculants in the air, such as hair, fiber, textile, are easily sticked to the mask and users can easily inhale them into their nostrils. Intsoft Tech’s industrial machine vision system can accurately identify flocs, and the detection accuracy of foreign matter diameter can reach 0.05mm.

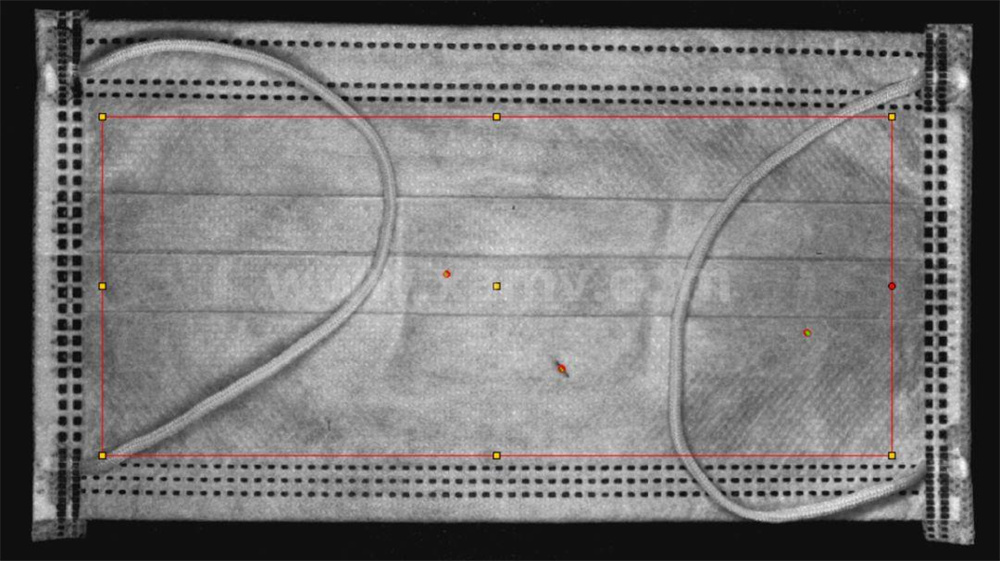

Front and back side of mask stain and mosquito contamination detection

Tiny mosquitoes can easily get on the front and back of the mask, causing contamination and making it unusable. Intsoft Tech’s industrial machine vision system can accurately identify dots, irregular black spots, and dirt, with a minimum area of 0.02mm².

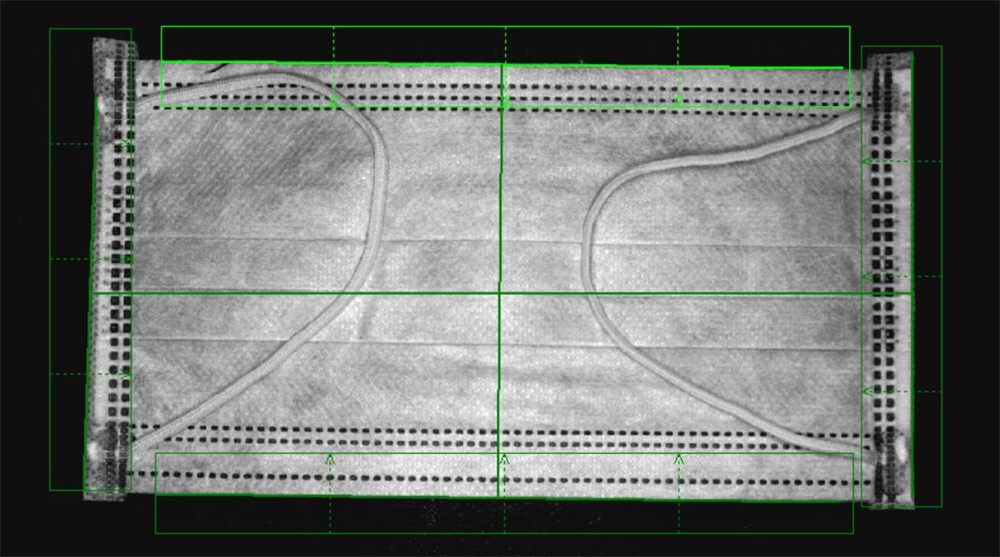

Face Mask dimension measurement

The length and width of masks have strict size requirements when they are automatically produced and cut. Intsoft Tech’s industrial machine vision system uses high-resolution industrial cameras to measure mask size with an accuracy of ±0.5mm.

Mask ear strap length measurement

The length of the ear strap is too long or too short, which will cause the mask to fit too tightly or too loosely to the face during use, and the use effect will be reduced. Intsoft Tech’s industrial machine vision system, using high-resolution industrial cameras, for measuring earband size accuracy ±0.5mm.

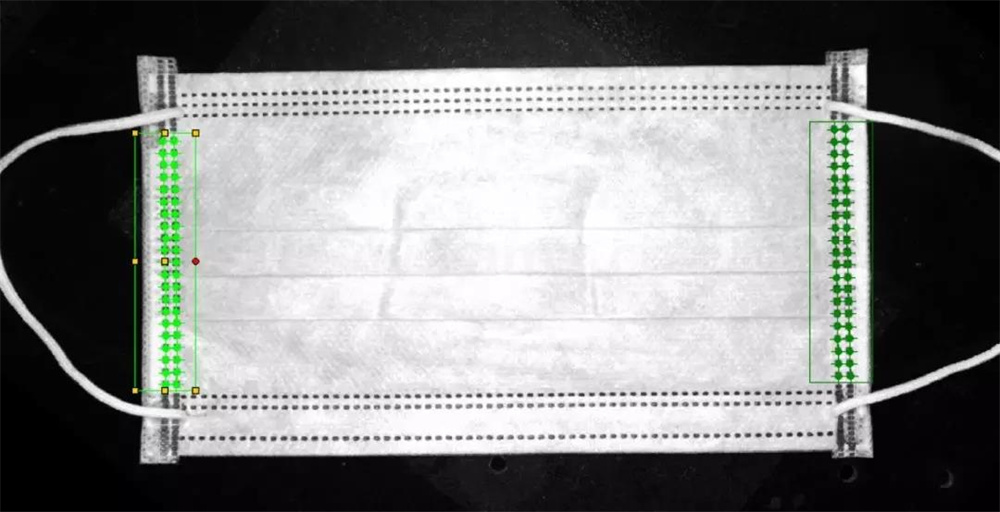

Mask anchoring point row inspection

Intsoft Tech’s industrial machine vision system can accurately detect the number, size, symmetry and with/without holes of anchoring point row on the mask to ensure that the face mask does not delaminate and that the metal strip is not out of shape.