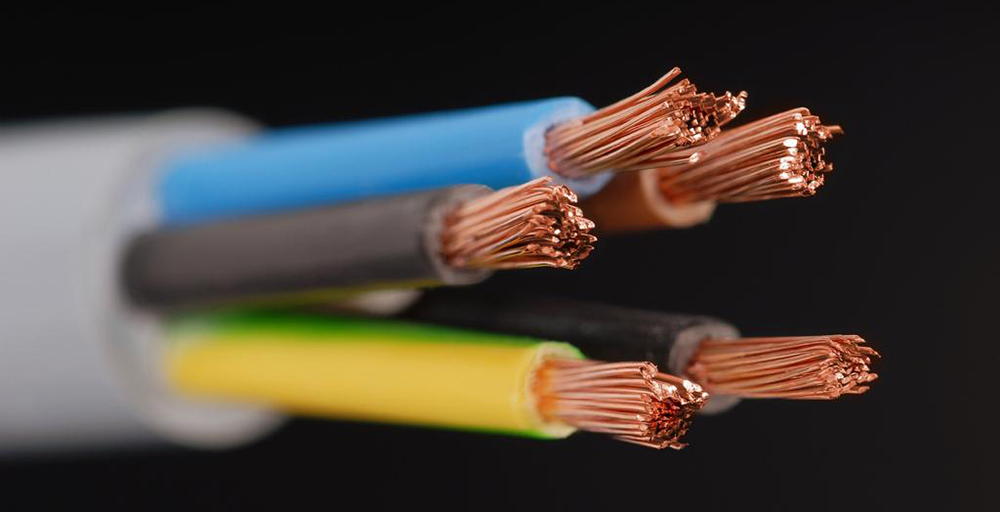

Generally, wiring harnesses are mainly used in the automotive industry and the electronics industry. As the main network of automotive circuits, automotive wiring harnesses are the core components of automotive circuits. The automotive industry attaches great importance to safety, so the quality of wiring harnesses needs to consider its safety, reliability and stability requirements.

At present, due to the development of the automotive and electronics industries, wiring harnesses are becoming more and more complex, but the space given to wiring harnesses by the car body is getting smaller and smaller. Therefore, how to improve the detection and quantity statistics of wiring harnesses has become the focus of manufacturers’ attention.

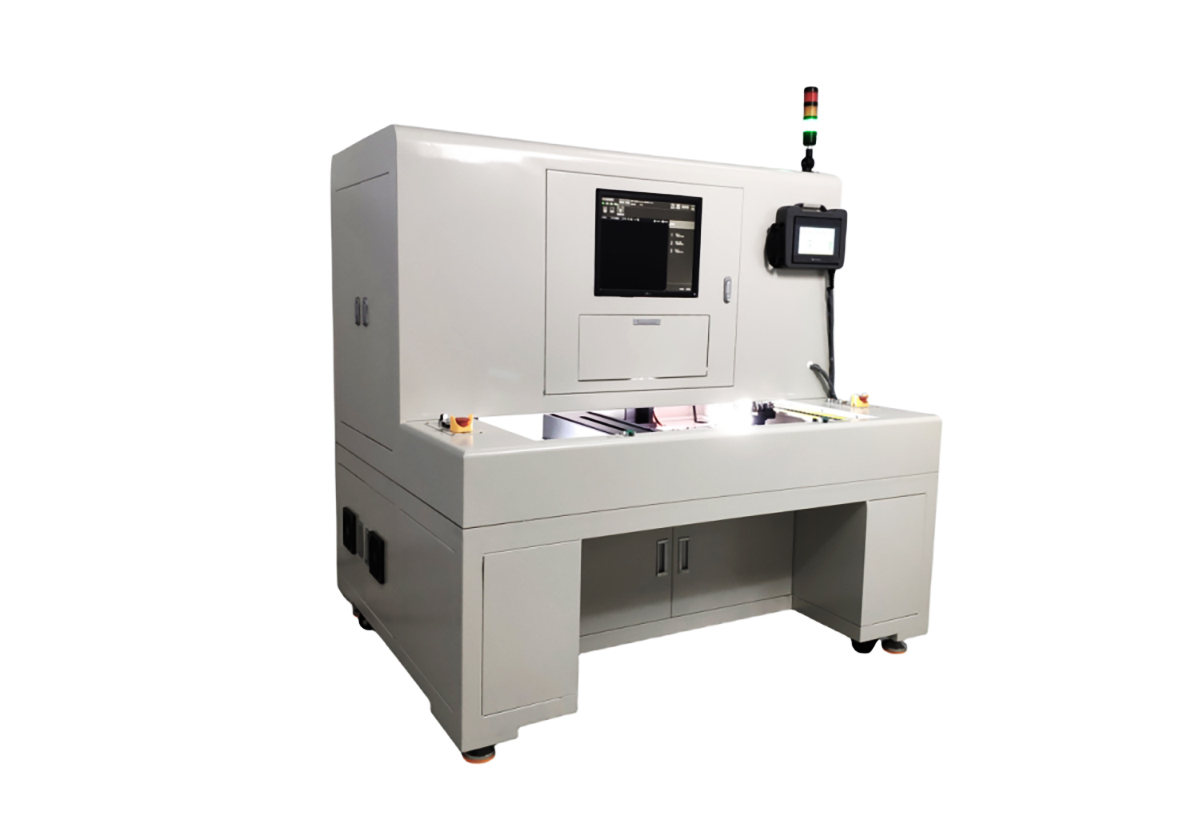

As shown in the figure below, a wiring harness requires the number to be counted, and at the same time, it is detected whether the terminal is riveted to the core wire inside. The traditional method is manual inspection. The time required for this inspection is estimated to be several minutes. However, using Intsoft Tech’s machine vision software’s counting and multi-target detection capabilities, it can be accurately detected within 1 second. Let’s analyze how AI-Intsoft machine vision software is implemented.

We follow the steps to show the visual inspection solution and the wiring harness quantity statistics solution for automotive wiring harnesses.

Step 1: Acquire image

The camera collects pictures, and then enhances and improves the image quality through preprocessing to improve image recognition. Then open the AI-Intsoft intelligent vision software, drag the feature search tool with the mouse, or calculate the tool. Two rectangular roi areas will appear on the interface, one is a larger red area (determine the search area), and the other is a pink area (determine the template area). The template is determined by dragging and added to the processing flow. Appropriate parameters can be adjusted to ensure the detection effect.

Achieve 100% wire harness detection. The number of wire harnesses in this detection effect is 505, which is exactly the same as the actual number.

Step 2: Multi-target detection scheme for wire harnesses

To detect so many wire harnesses, another AI-Intsoft detection tool, multi-target detection, is also very simple and can be used quickly by workers on site.

In position customization, select the above counting tool (i.e. feature counting) with reference to the position, and you can detect the products counted by feature counting.

Right-click “Position Customization” to enter the custom module editing and enter another editing interface. The detection object is the counting target of “feature counting”.

By testing the counting target in the new editing interface, all 505 detected products can be tested. For example, the following adds only a luminance tool to determine the gray value in the counting target to detect whether there is a missing core.