This is the second time we went to our client’s factory, a condom manufacturer, to maintain the machine vision equipment. They wanted to add another production line and further increase the inspection speed from the original 180pcs/min to 240pcs/min.

As a leading provider of machine vision integration solutions, Intsoft Tech was commissioned by a leading condom manufacturer to maintain and optimize their state-of-the-art condom inspection system last year. This partnership demonstrates Intsoft Tech’s commitment to delivering cutting-edge technology and unparalleled technical expertise to support the stringent quality control requirements of the personal health care industry.

Leveraging advanced machine vision technology

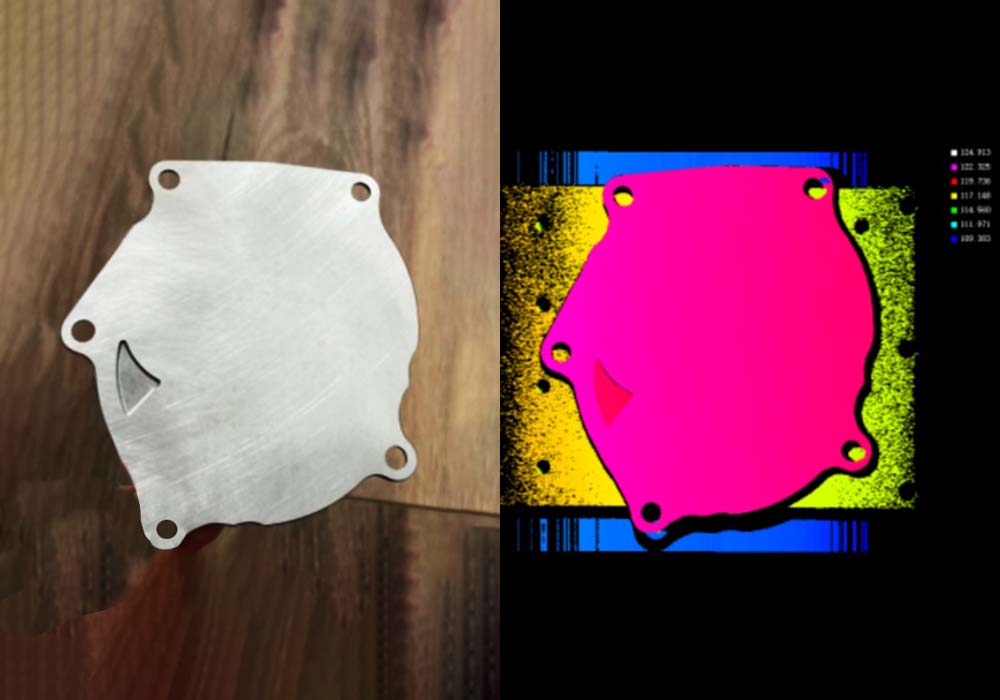

The condom manufacturer’s inspection system, designed and implemented by Intsoft Tech, uses a sophisticated combination of high-resolution cameras, specialized lighting, and intelligent algorithms to meticulously examine each condom that comes off the production line. This advanced machine vision technology is capable of detecting even the most subtle defects, including microscopic holes, uneven thickness, and surface blemishes.

“Ensuring the quality and safety of our condom products is of the utmost importance,” said Jane Doe, condom manufacturer’s Quality Assurance Manager. “Intsoft Tech’s machine vision solution has been instrumental in upholding our high standards and giving our customers the confidence they deserve.”

Dedicated technical support: continuous improvement

Maintaining the optimal performance of the condom inspection system is a critical responsibility entrusted to Intsoft Tech’s experienced technical team. These skilled professionals work closely with the condom manufacturer’s team, perform regular maintenance, troubleshoot any problems, and ensure that machine vision technology is always running at peak efficiency.

“Our technicians are not only experts in the intricacies of machine vision, but they also have a deep understanding of the unique requirements of the condom manufacturing industry,” said Zhao, Intsoft Tech’s Service Manager. “This allows us to provide tailored support and drive continuous improvements to the inspection process.”

Empowering Quality Assurance and Compliance

By entrusting their condom inspection process to Intsoft Tech, the condom manufacturer has been able to streamline their quality control efforts and ensure compliance with the industry’s stringent regulations. The machine vision system’s comprehensive data collection and analytics capabilities provide valuable insights, enabling manufacturers to identify trends, pinpoint recurring issues, and implement targeted corrective actions.

“Intsoft Tech’s expertise and commitment to excellence have been instrumental in helping us maintain our position as a trusted leader in the condom industry,” Lan Ming said. “Their machine vision solution and dedicated technical support have been invaluable in our pursuit of uncompromising quality and safety.”

As the condom manufacturer continues to grow and innovate, Intsoft Tech remains a trusted partner, committed to providing cutting-edge technology and unparalleled technical expertise to support their quality control efforts and drive continuous improvement.