In the highly competitive market, maintaining production efficiency and quality control is crucial. Recently, Intsoft Tech partnered with a leading laptop interface manufacturer to help them upgrade the visual inspection system on their production line to meet the latest order requirements.

As a technology company focused on industrial automation and AI applications, Intsoft Tech has extensive experience in areas such as visual inspection, machine learning, and factory digitalization. This manufacturer has recently received a large order from a well-known laptop brand, but their existing manual inspection process can no longer meet the increasing production requirements. Facing pressure on both time and labor costs, they urgently needed a more efficient and intelligent inspection solution.

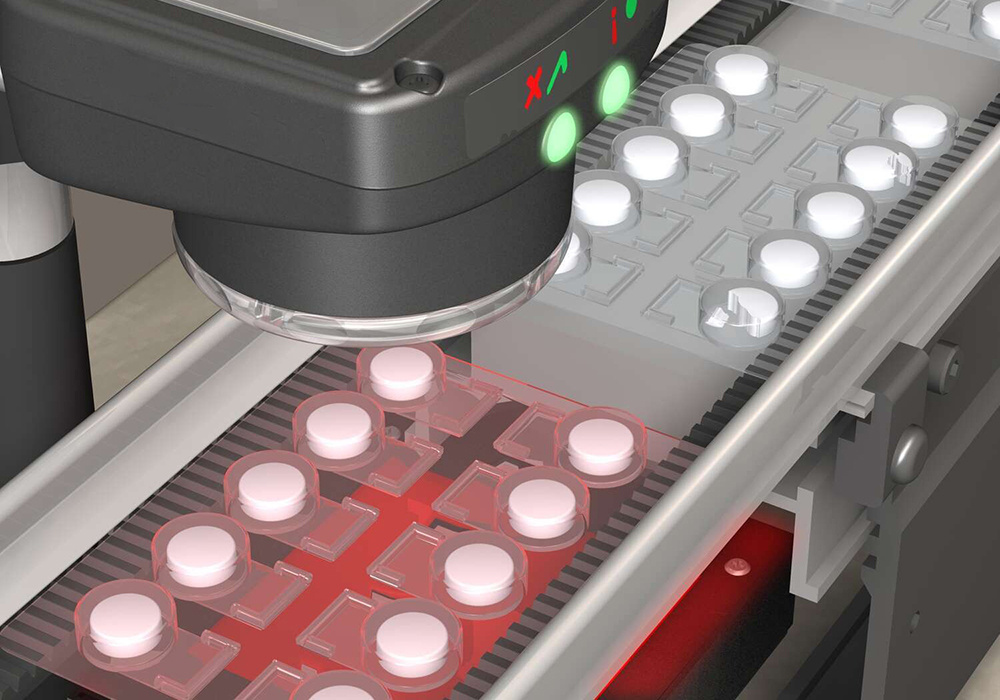

The Intsoft Tech engineering team, after thoroughly understanding the customer’s production process and requirements, has customized an intelligent visual inspection system for them. The system employs advanced machine vision algorithms and high-performance industrial cameras to comprehensively inspect key indicators of the laptop interface, such as appearance, dimensions, and connection status. At the same time, the system is also equipped with machine learning models that can automatically identify and distinguish qualified and unqualified products, significantly improving the accuracy and consistency of the inspection.

“Our production line transformation plan has encountered some bottlenecks, mainly because the efficiency of manual inspection cannot keep up with the growth of orders,” said the manufacturer’s production manager. “The Intsoft Tech team is very professional, they deeply understood our specific needs and proposed a practical solution. With the intelligent visual inspection system, we not only solved the capacity problem, but also greatly improved the product quality.”

Intsoft Tech’s visual integration solution is not only applicable to the field of notebook interface manufacturing, but also plays an important role in various other industrial manufacturing scenarios. The company has a team of experts in machine vision, algorithm engineering and automation, who can provide comprehensive services from system design, algorithm optimization to on-site implementation based on customers’ specific requirements.

“We have been committed to empowering the manufacturing industry with cutting-edge technologies, helping enterprises improve production efficiency and ensure product quality,” said Michael Zhao, founder and CEO of Intsoft Tech. “Through this successful collaboration with the laptop interface manufacturer, we have further validated our technical capabilities and the effectiveness of our solutions. We will continue to focus on innovative applications of industrial automation and artificial intelligence, creating value for more customers.”

Intsoft Tech’s intelligent visual inspection system has been stably operating on the manufacturer’s production line for several months, not only significantly improving inspection efficiency and reducing labor burden, but also greatly reducing the occurrence of unqualified products, bringing considerable economic benefits to the customer.