U-shaped hardware accessories surface defect detection, double-leg deformation identification

Inspection content and requirements

1. Top backlight detection

2. Side backlight detection

Detection efficiency: the number of detection per minute is not less than 160-220 pieces (depending on the product feeding speed).

Inspection process

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Barsler industrial camera | 2 sets | |

| 5 | Industrial lens | Intsoft customized | 2 sets | Fix focus telecentric lens |

| 6 | Professional glass disc | 1 sets | ||

| 7 | Solenoid valve | 360° detectable industrial camera | 1 sets | |

| 8 | Reducer | Customized optical adaptive light source | 1 sets | |

| 9 | Vibration mechanism | Professional Optical Glass Carrier | 1 set | |

| 10 | Feeding mechanism | Panasonic | 1 set |

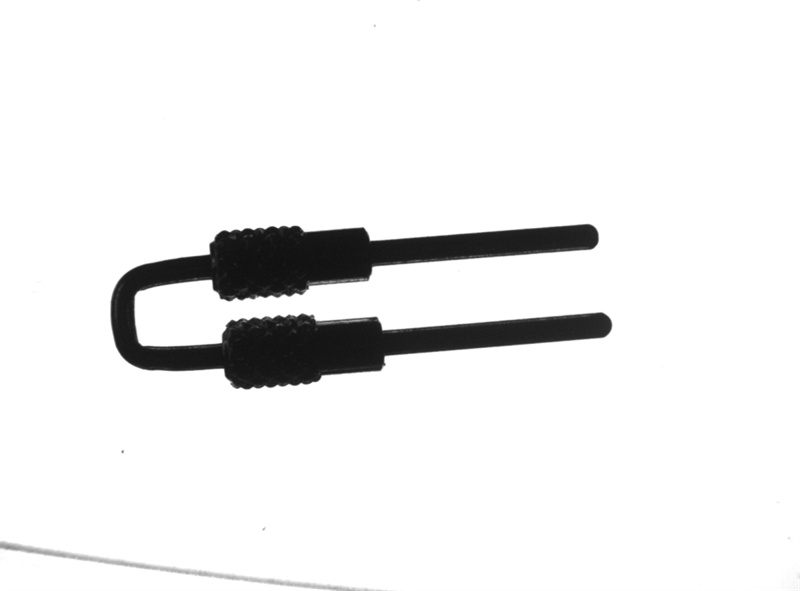

Detected product original image

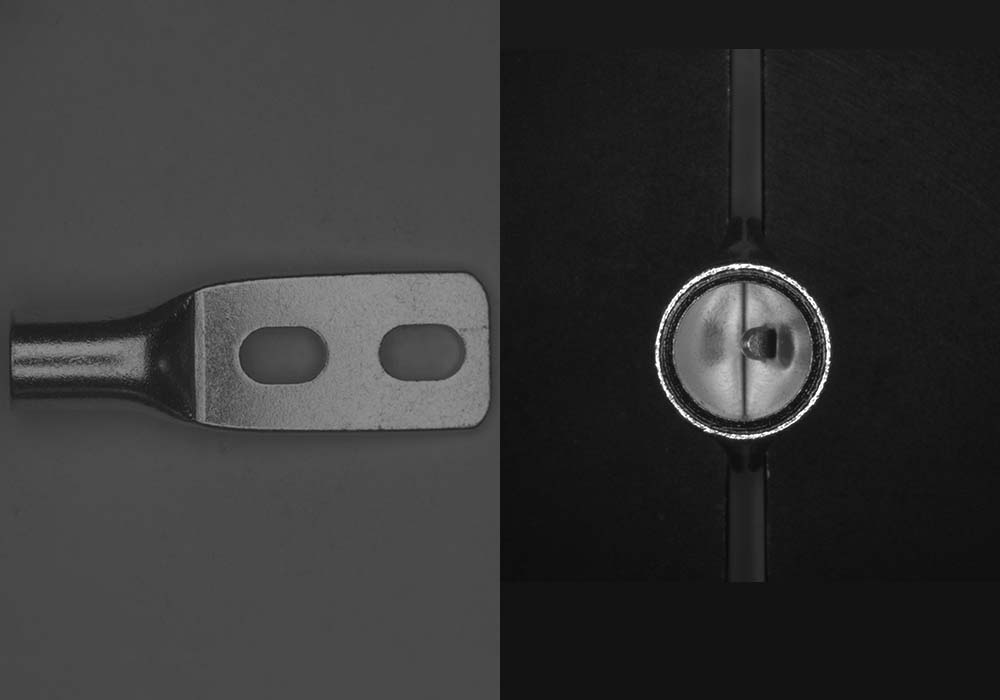

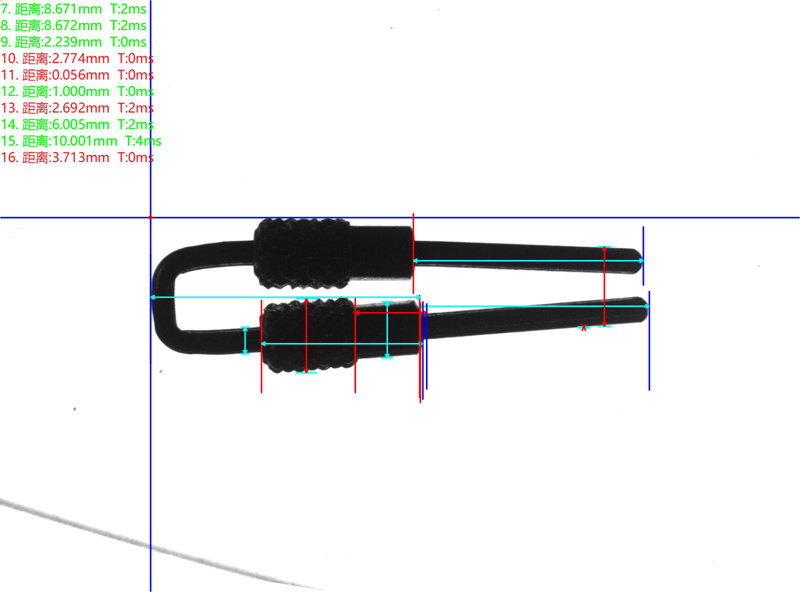

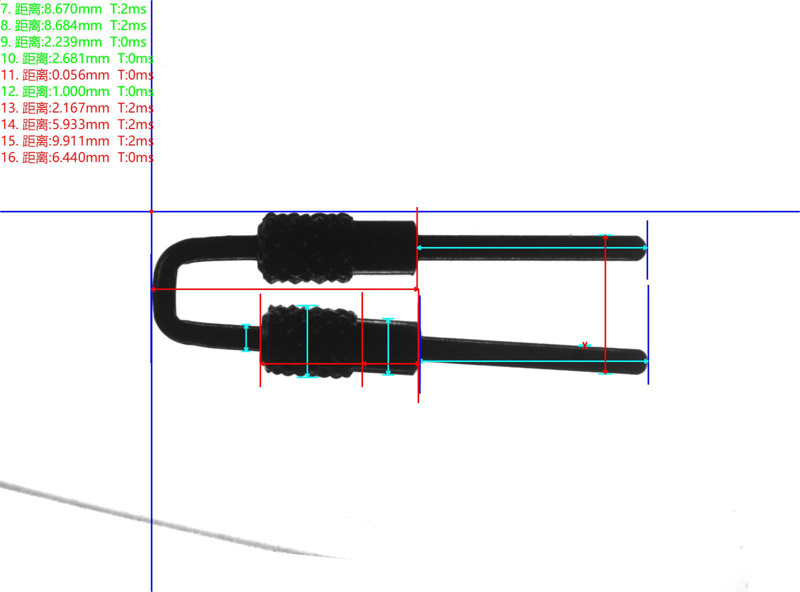

Top detection

Original image

Positive light detection original image

Good product analysis image: OK

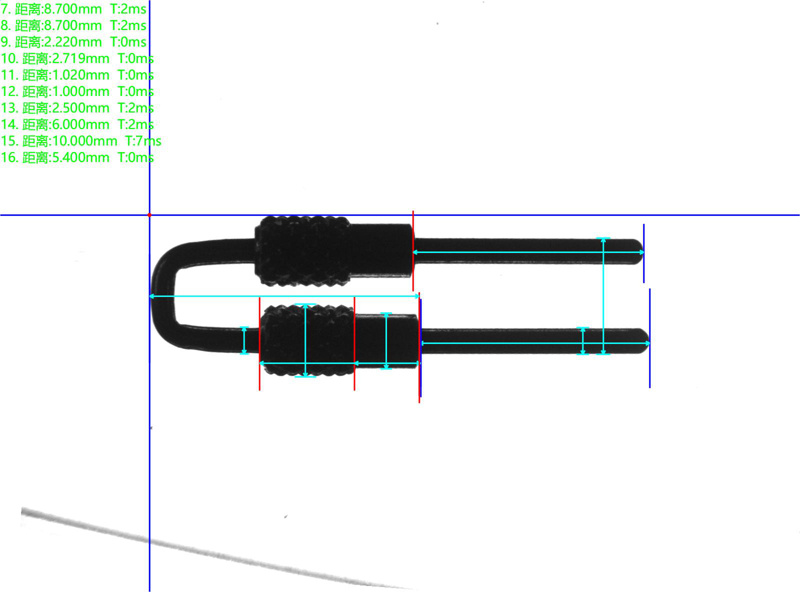

Defective product analysis image: NG cause of defect: Bend inward

Defective product analysis image: NG cause of defect: Ben outward

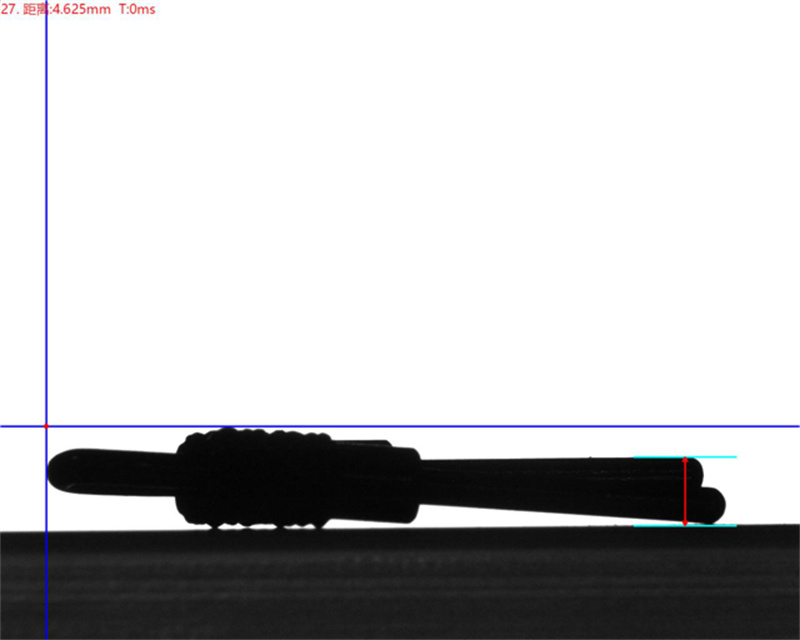

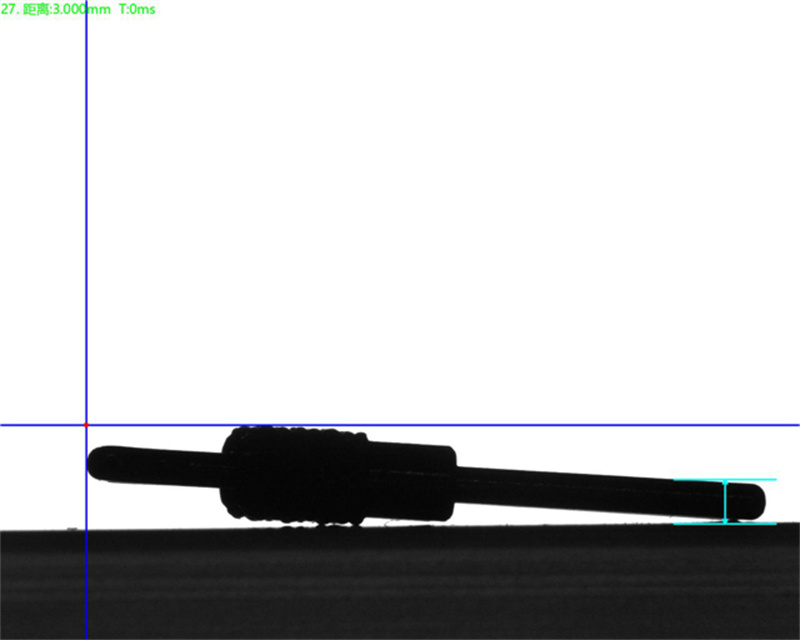

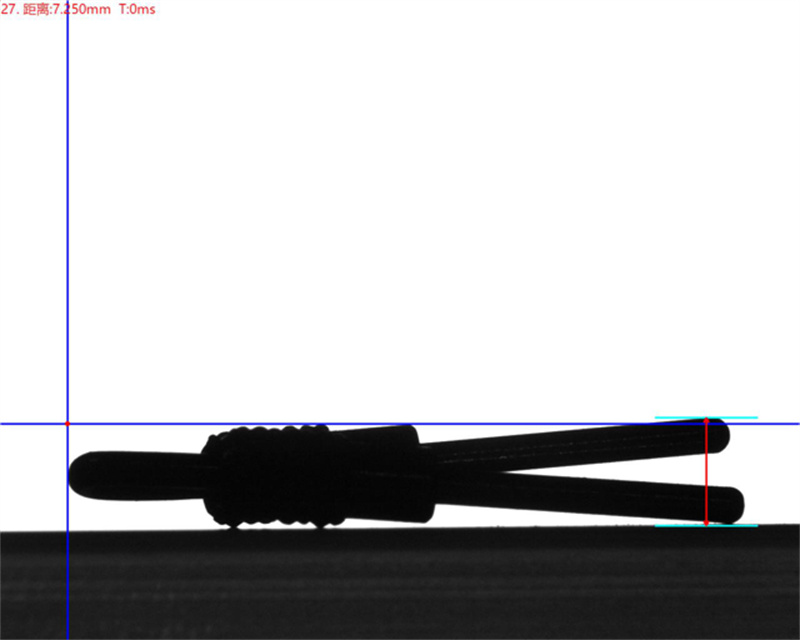

Side detection

Good product analysis image: OK

Defective product analysis image: NG cause of defect: Malalignment

Defective product analysis image: NG cause of defect: Malalignment