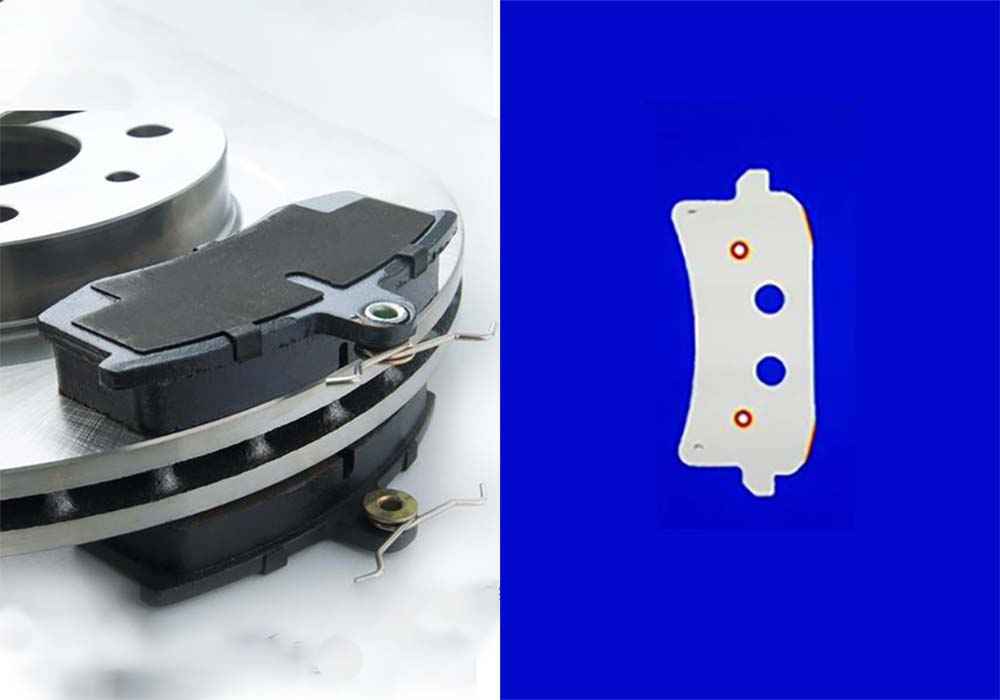

Rubber seals are a versatile and essential component in a wide range of applications, from automotive and industrial equipment to electronics and aerospace systems. Crafted from elastomeric materials such as nitrile, silicone, or fluoroelastomers, these seals create a tight barrier that prevents the leakage of liquids, gases, or contaminants. Designed in various shapes and profiles, such as o-rings, gaskets, and custom-shaped seals, rubber seals work by conforming to mating surfaces, leveraging their compressibility and elasticity to maintain a consistent seal even in demanding environments.

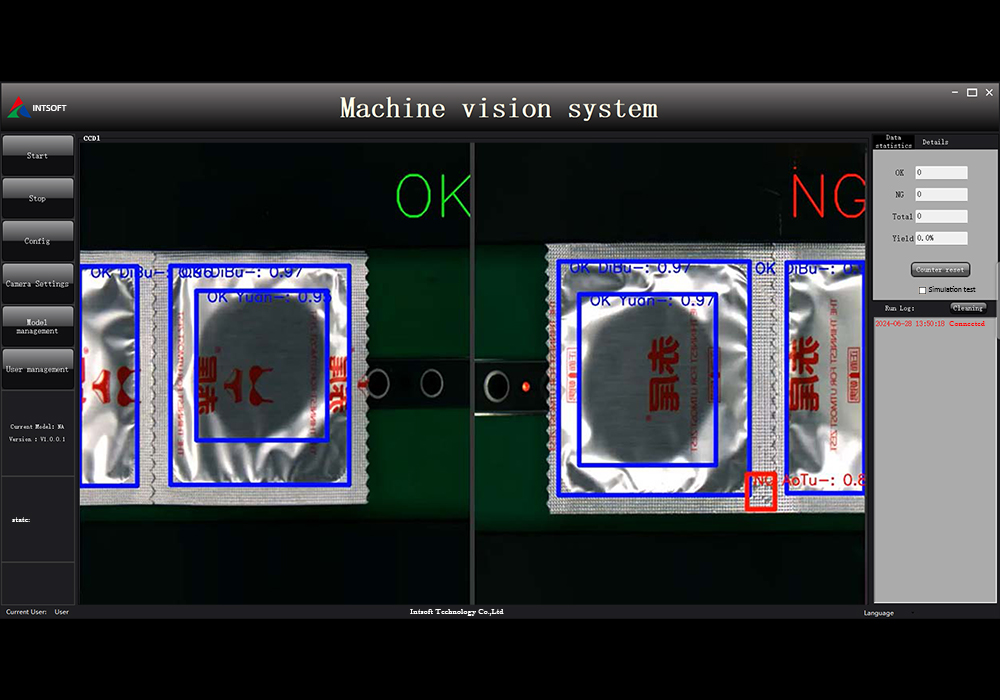

Since rubber seals are so important, eliminating defective seals during production is essential. The following is an example of machine vision inspection of rubber sealing rings shared by Intsoft Technology.

Detection requirements

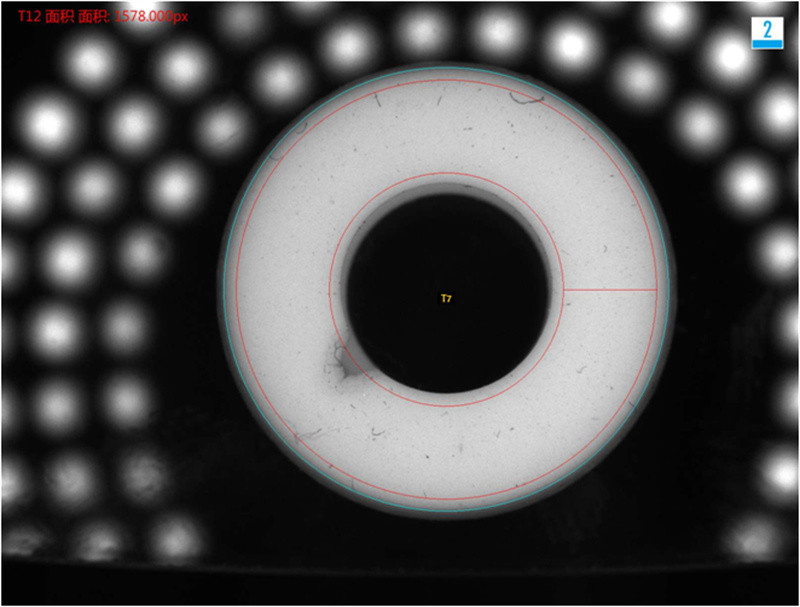

Area of detected item: 17*6 mm ring shape rubber seal

Contents:

1. Bottom surface stain and gaps detection

2. Side 45°surface stains detection

3. Topsurface stains and gap detection

Intsoft defect detection machine structure

Machine structure

Overall dimension: 900*800*1850mm

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Barsler industrial camera | 5 sets | 2*bottom back light / 2*ring white light |

| 5 | Industrial lens | Intsoft customized | 5 sets | 5*FA industrial lens |

| 6 | Professional glass disc | 1 sets | ||

| 7 | Solenoid valve | 360° detectable industrial camera | 1 sets | |

| 8 | Reducer | Customized optical adaptive light source | 1 sets | |

| 9 | Vibration mechanism | Professional Optical Glass Carrier | 1 set | |

| 10 | Feeding mechanism | Panasonic | 1 set |

Detection process

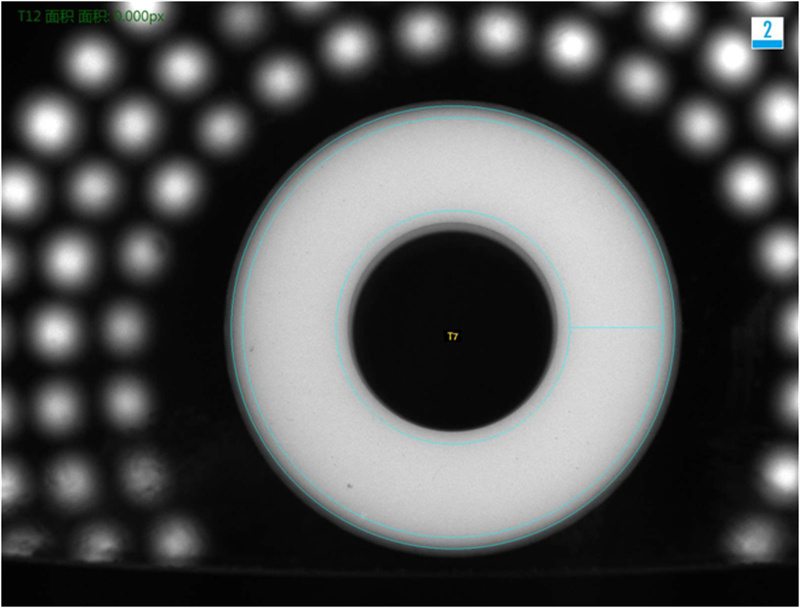

Bottom detection

Bottom detection good product analysis image: OK —

Bottom detection defective product analysis image: OK cause of defect: Gap —

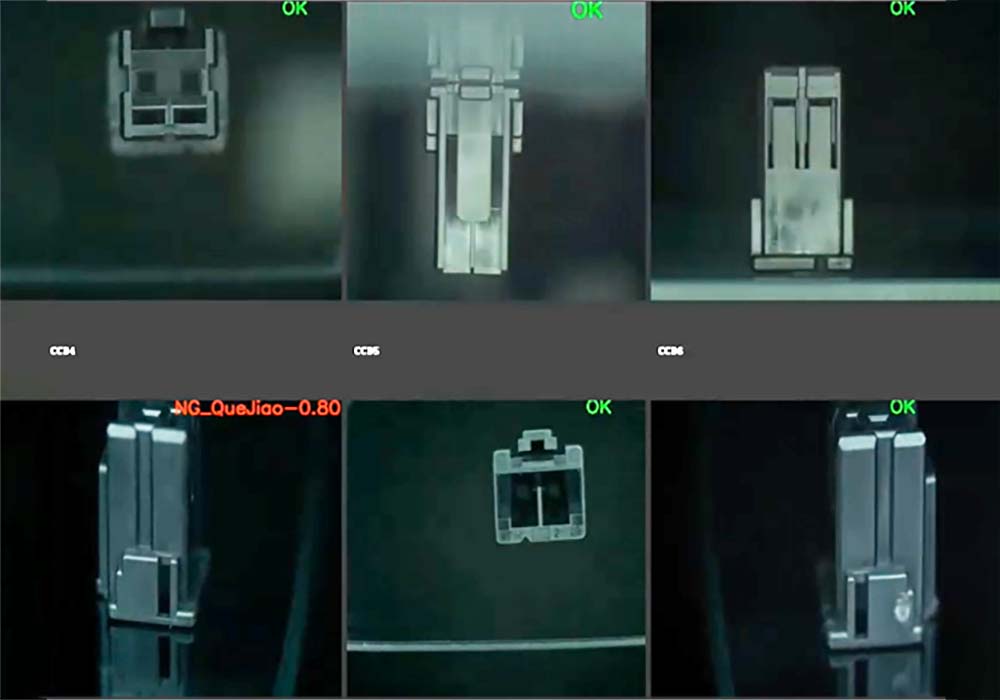

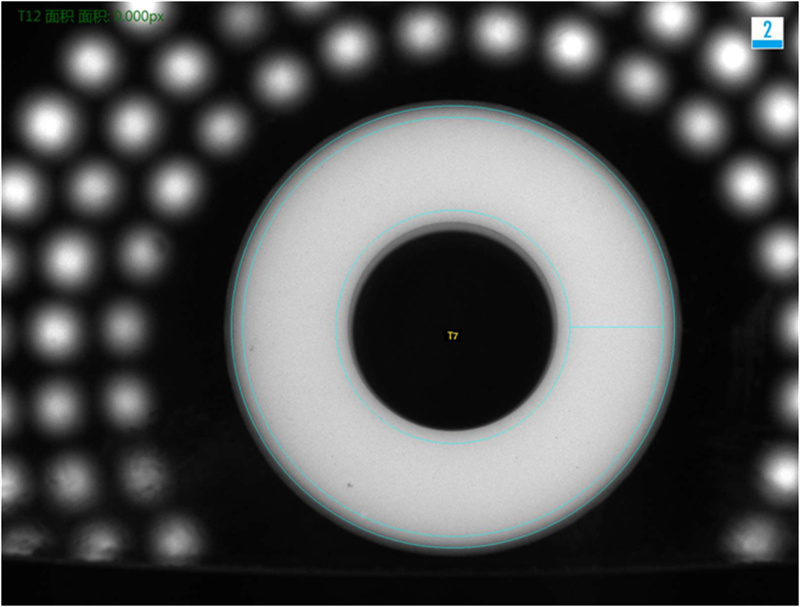

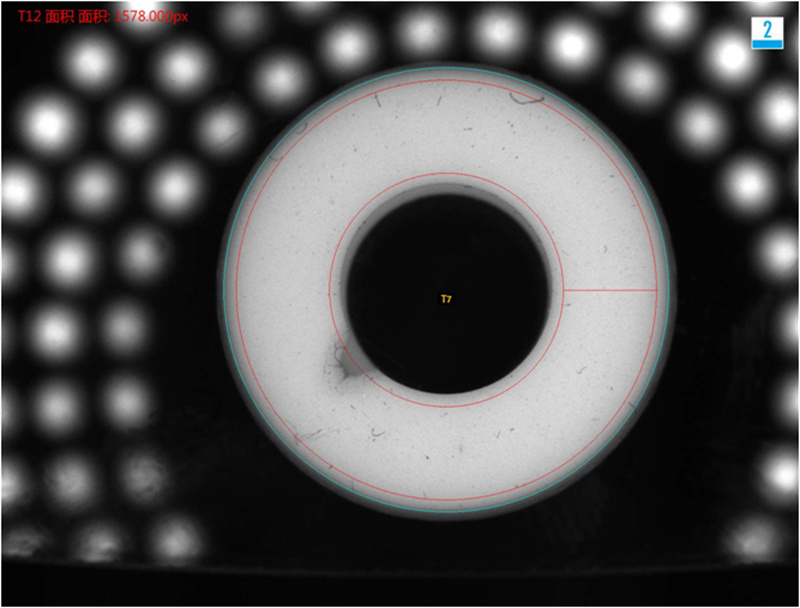

Side 45°

Side 45° detection good product analysis image: OK —

Side 45° detection defective product analysis image: NG cause of defect: slight stain —

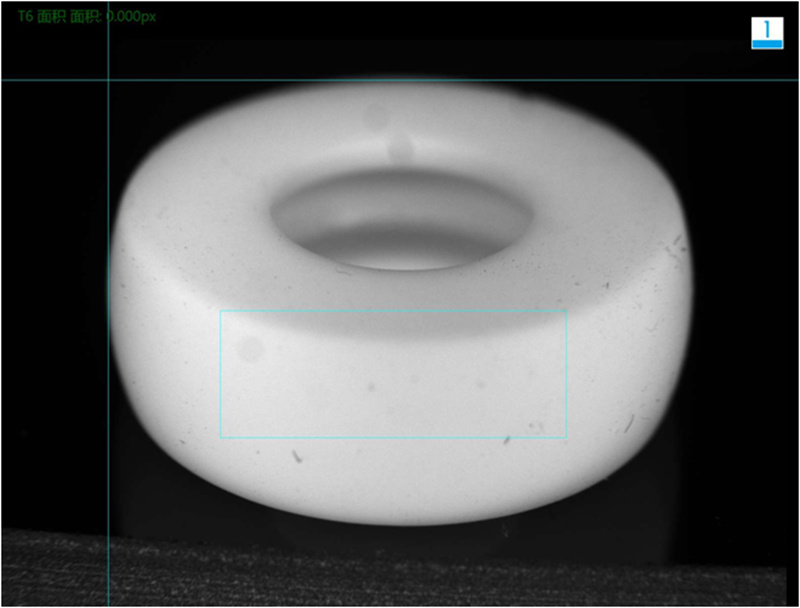

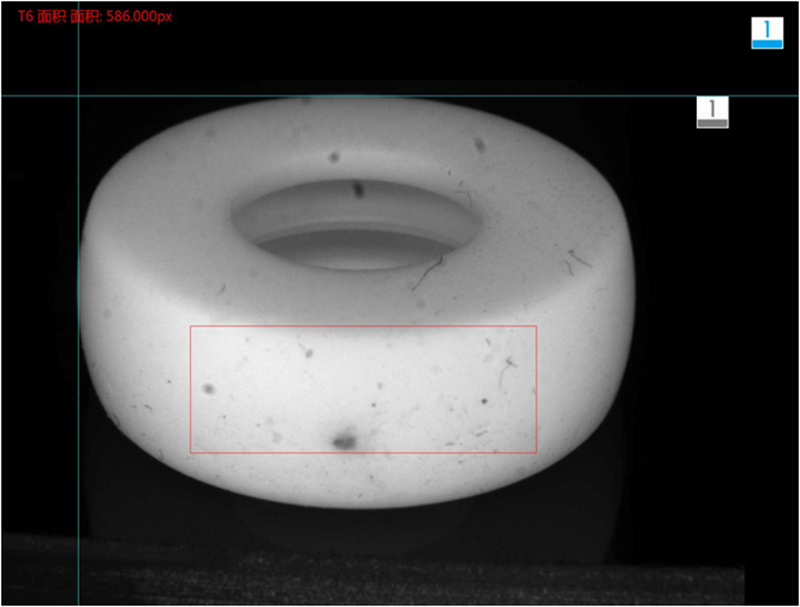

Top

Top detection good product analysis image: OK —

Top detection defective product analysis image: NG cause of defect: gap —