Machine vision is essential for the gear surface defect detection in manufacturing and maintenance practices with today’s technology. Alternatively, automated machine vision systems inspect gear surfaces a level of precision and consistency well beyond human capabilities, so that even the smallest surface defects can be quickly identified. This is critical to enabling the predictability and quality of gear-based mechanical systems found in virtually all automotive, industrial machinery and aerospace applications. This not only helps in integrating real-time, monitor & data-driven insights, increases the safety &, efficiency of the equipment but also many more industries are targeted to optimise the production lines & lower costs related to product rework & warranty claims etc. through the gear surface defect detection algorithm. As the Sodick system demonstrates, in today’s hypercompetitive, high-tech manufacturing environment, the application of machine vision to the measurement of gears on a gear surface gear clients.

Below is a case of gear surface defect detection from Intsoft Technology.

Detection content and requirements

Max. Dia. 20mm, height 9.5mm gear appearance defect detection

| NO. | Position | Method | Detectability |

| 1 | Incomplete filling, burr | Positive detection | YES |

| 2 | Incomplete filling, burr | Positive detection | YES |

Note: The image of above inspection items must be clearly visible for inspection

Inspection efficiency: No less than 150 pieces per minute (depending on sample feeding speed).

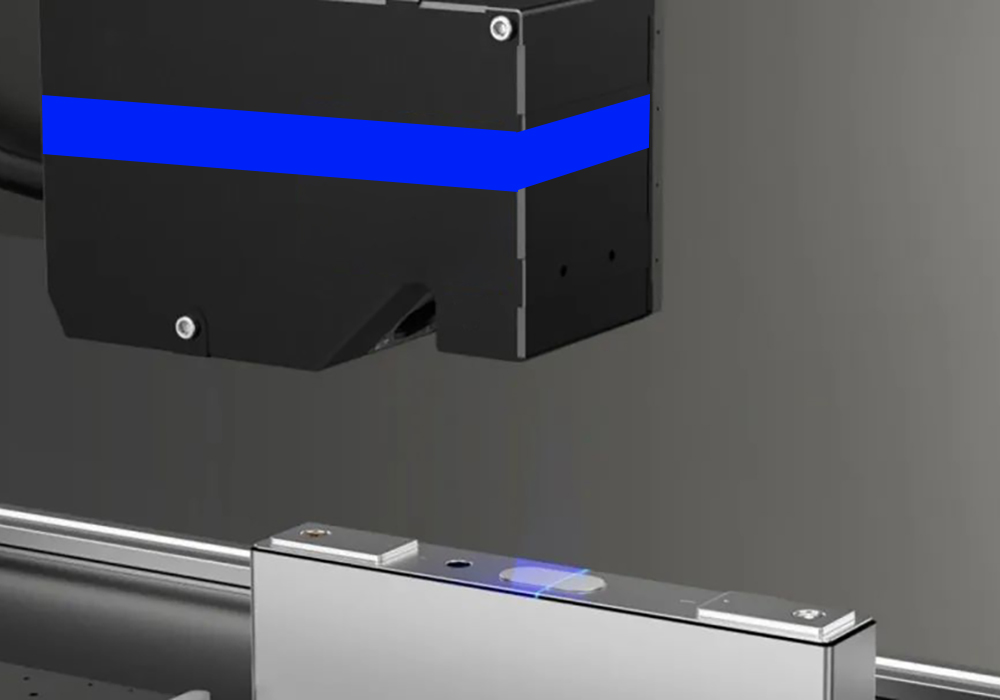

Machine composition

Model: YTD-T300 customized machine

Overall dimension: 900*800*1850mm

Partial list of component:

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be uploaded |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Barsler industrial camera | 2 sets | |

| 5 | Servo Module for Camera Adjustment | Intsoft customized | 2 sets | |

| 6 | Industrial lens | FA High Definition Optical Industrial Lens | 2 sets | |

| 8 | Light source | Customized optical adaptive light source | 4 sets | |

| 9 | Inspection Platform | Professional Optical Glass Carrier | 1 set | |

| 10 | Servo Motor | Panasonic | 1 set | |

| 11 | Control System | Intsoft customized | 1 set | |

| 12 | PLC motion collaboration | Panasonic | 1 set |

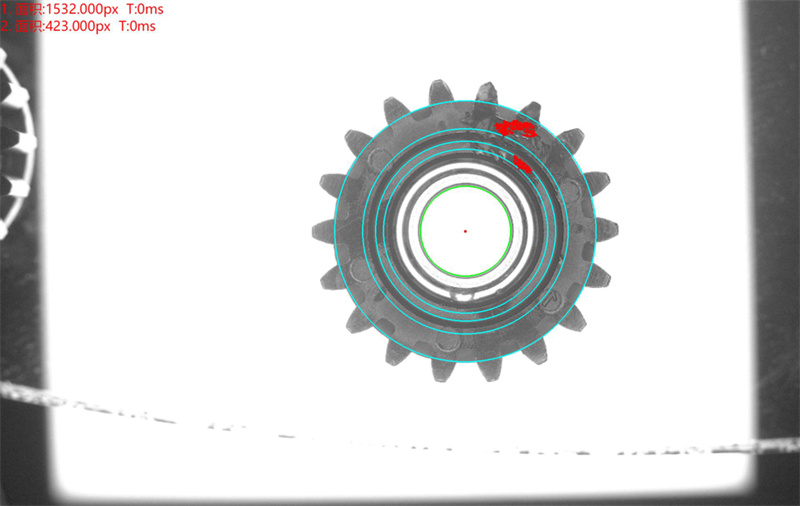

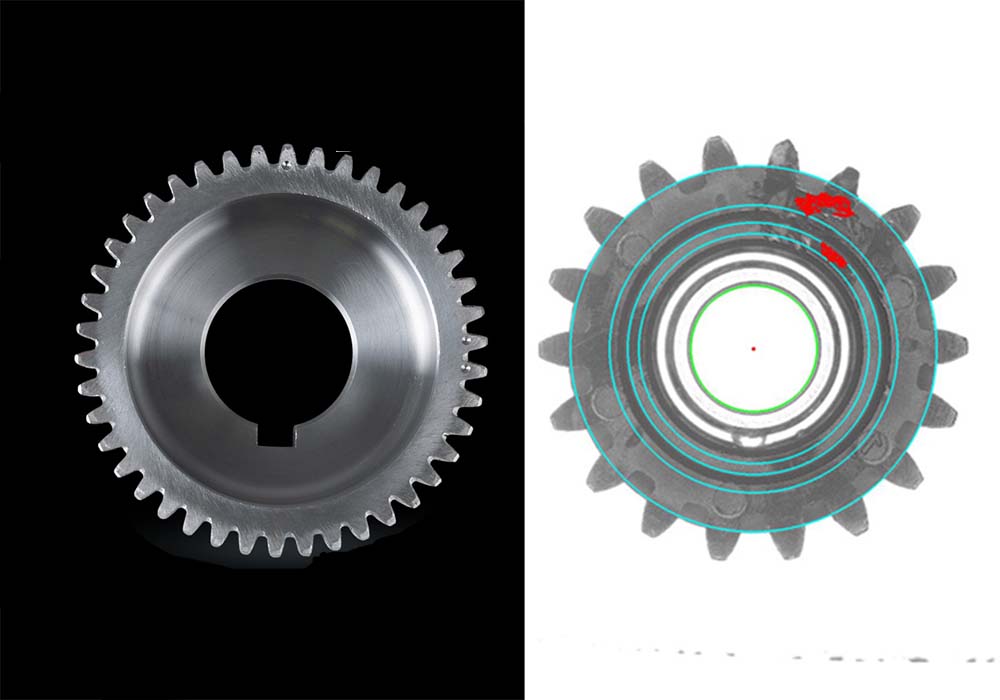

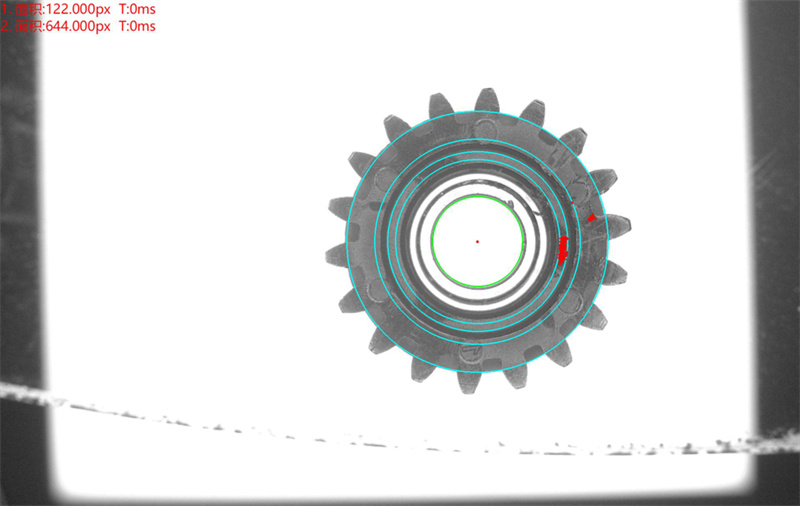

Sample detection image

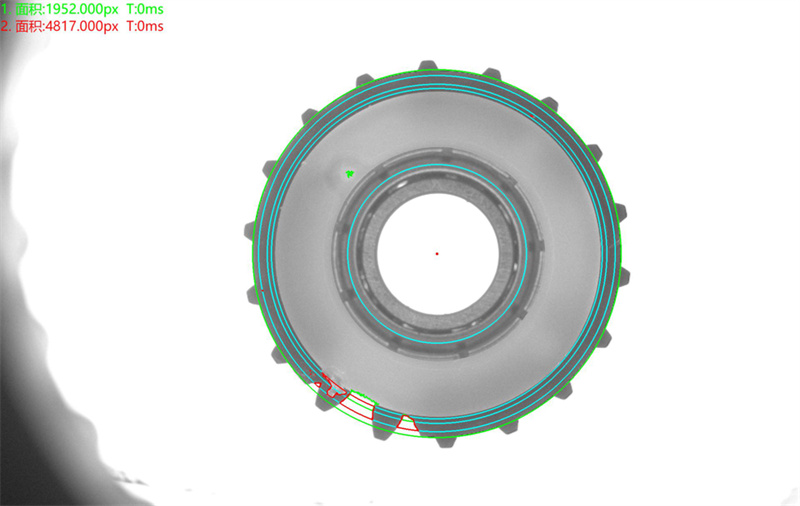

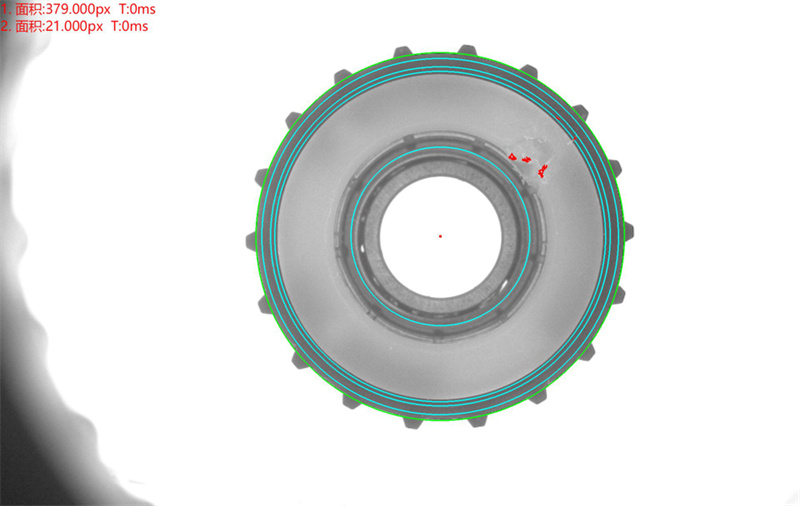

Bottom detection

Positive light detection image:

Positive light detection good product analysis image: OK

Positive light detection defective product analysis image: NG cause of defect: burr, incomplete filling

Positive light detection defective product analysis image: NG cause of defect: burr, incomplete filling

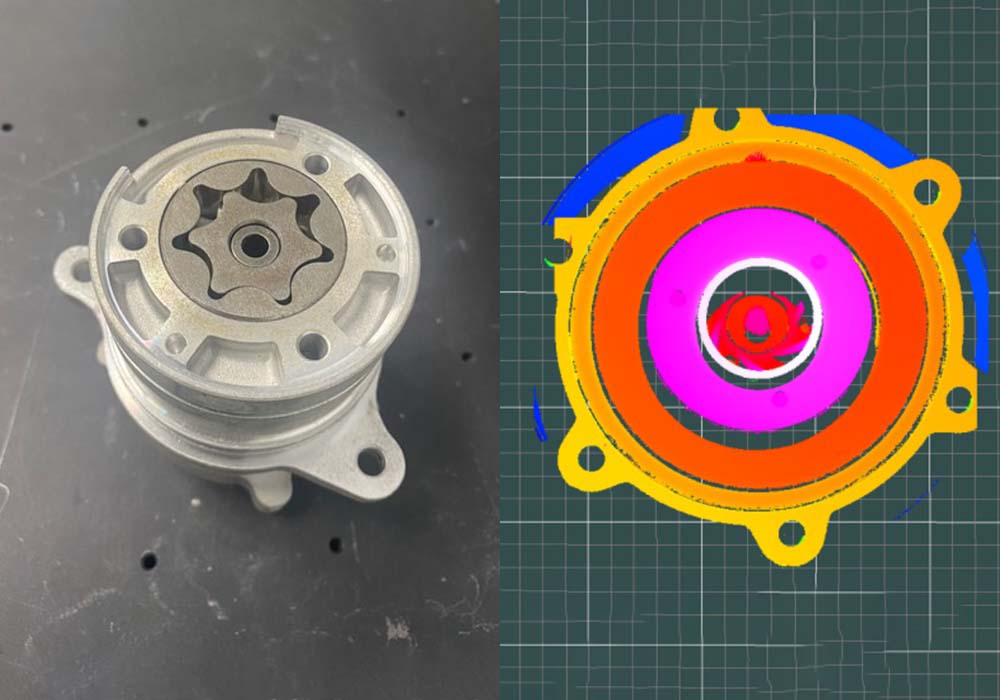

Top detection

Positive light detection defective product analysis image: NG cause of defect: burr, incomplete filling

Positive light detection defective product analysis image: NG cause of defect: burr, incomplete filling