The current coffee market is very large, and therefore there are many segmented demands, which mainly include: the pursuit of health and environmental protection, preference for personalized customization, desire for high-quality boutique coffee, and focus on convenience and diversity. However, these market demands must be based on quality. The quality of coffee beans as raw materials directly affects the market competitiveness of coffee producers. Only by having advantages in quality can coffee maker stand out in the competition.

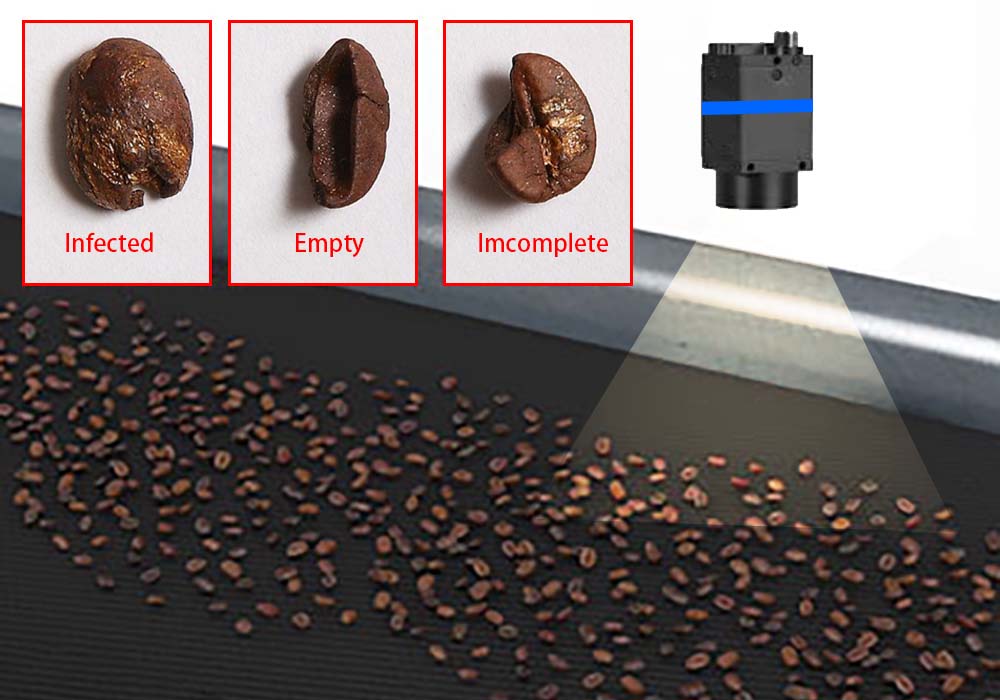

Taking a well-known coffee producer as an example, they introduced an intelligent detection system based on machine vision. The system uses a high definition CCD camera and an LED light source with a PLC to capture ultra-clear images of each coffee bean. These images are then fed into a pre-trained deep learning algorithm, which processes and enhances the images, highlights the characteristics of the coffee beans, and automatically identifies and evaluates the color, size, shape, defect and other indicators of the coffee beans.

Through a large number of sample training, the recognition accuracy of the algorithm has reached more than 99%, far exceeding the level of manual visual inspection. The system will classify coffee beans into different grades according to preset evaluation criteria. For low quality coffee beans with uneven color and obvious deformation defects, the system automatically removes them to avoid flowing into the subsequent packaging link.

In addition to improving detection accuracy, this intelligent vision system can also greatly improve detection efficiency. Compared to the traditional manual inspection of each bean, the machine vision system can scan the entire production batch of coffee beans at the speed of dozens of beans per second. This not only greatly shortens the detection cycle, but also ensures that the quality of each batch of coffee beans can be reliably controlled.

Data recording and automatic deep learning are also a highlight of the machine vision system. The detected defect or feature data will be used as training material for deep learning, making subsequent appearance inspection faster and more accurate.