Usually, the bottle cap is made of plastic through the injection molding process, coupled with today’s environmental protection, with the quality of recycled materials varying, these factors inevitably cause a variety of defects, common such as appearance defects: deformation, burrs, surface roughness, etc., such as size defects: diameter deviation, height inconsistency, wall thickness is not uniform, such as material defects: bubbles, cracks, color difference, pollution.

Below is a case study from Intsoft Tech on bottle cap machie vision defect detection.

Detection content

| No. | Defect type | Method | Detectable or not |

| 1 | Black spot | Positive light detection | YES |

| 2 | Gap | Positive light detection | YES |

| 3 | Scratch | Positive light detection | YES |

| 4 | With or without thread | Bevel detection | YES |

| 5 | Anti-theft ring | NO |

Note: All images of detected items should be clearly visible for detection by Intsoft Tech’s equipment.

Detection efficiency: More than 120 pieces per minute (depending on the feeding speed of the product)

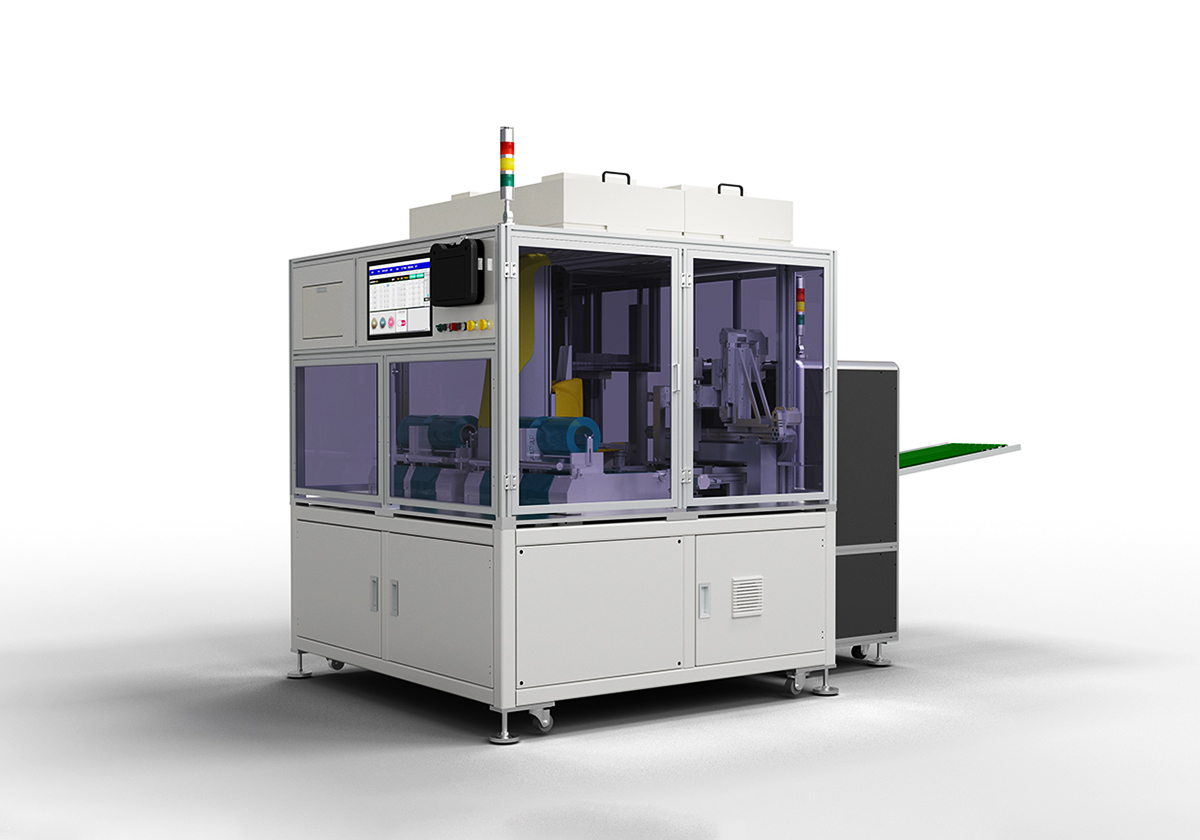

Machine structure

Name: High-speed inspection machine with square 2-port unloading.

Overall dimension: 950*850*1850mm

| No. | Name | Model | Quantity | Remark |

| 1 | Visual inspection software | Intsoft customized | 1 set | Data can be upload |

| 2 | Industrial computer | Intsoft customized | 1 set | |

| 3 | Monitor | PHILIPS 19 “LCD monitor | 1 set | |

| 4 | Industrial camera | Sony industrial camera | 4 sets | 2*bottom positive light / 2*top positive light |

| 5 | Camera adjustment module | Intsoft customized | 4 sets | 4*FA industrial lens |

| 6 | Industrial lens | Telecentric HDV lens | 4 sets | |

| 7 | Ring light source | 360° detectable industrial camera | 4 sets | |

| 8 | Control system | Customized optical adaptive light source | 1 sets | |

| 9 | Servo motor | Panasonic | 1 set | |

| 10 | Reducer | Intsoft customized | 1 set |

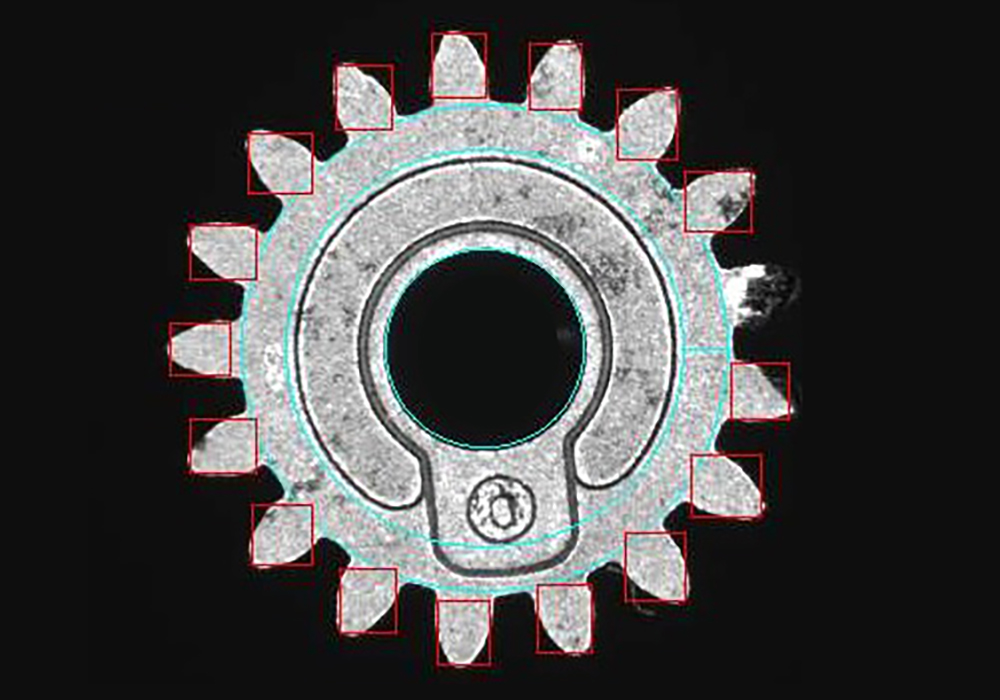

Image of detected item

Bottom detection

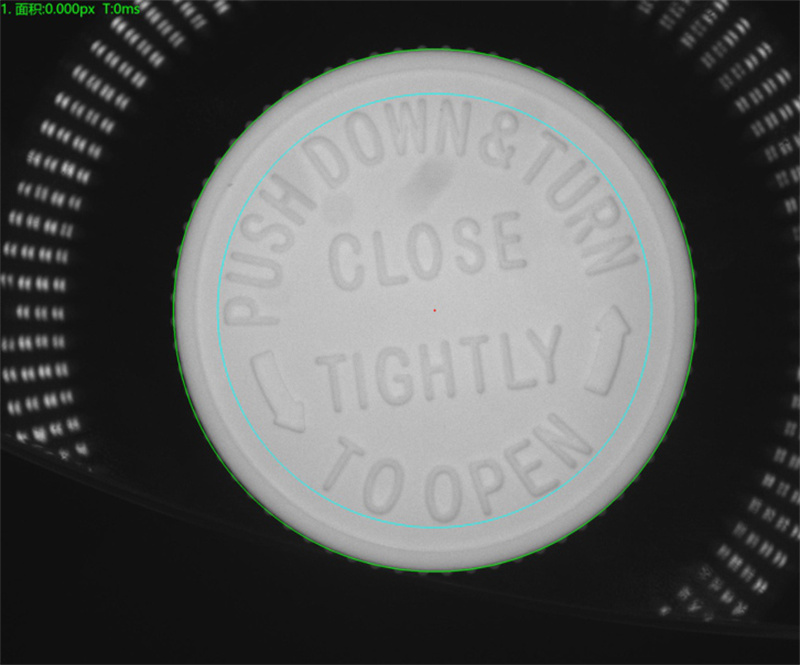

Bottom positive light good product original image: OK —

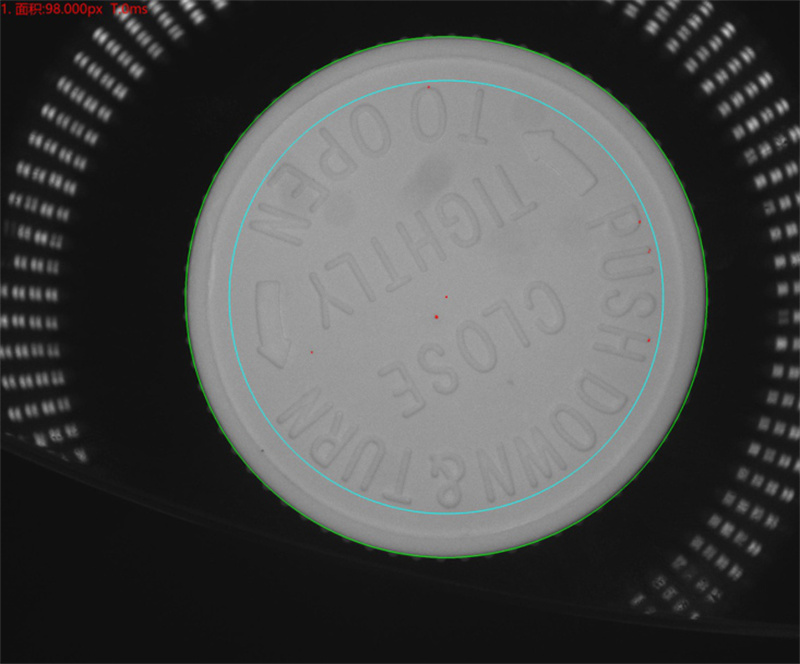

Bottom positive light defect product analysis image: NG cause of defect: black spot —

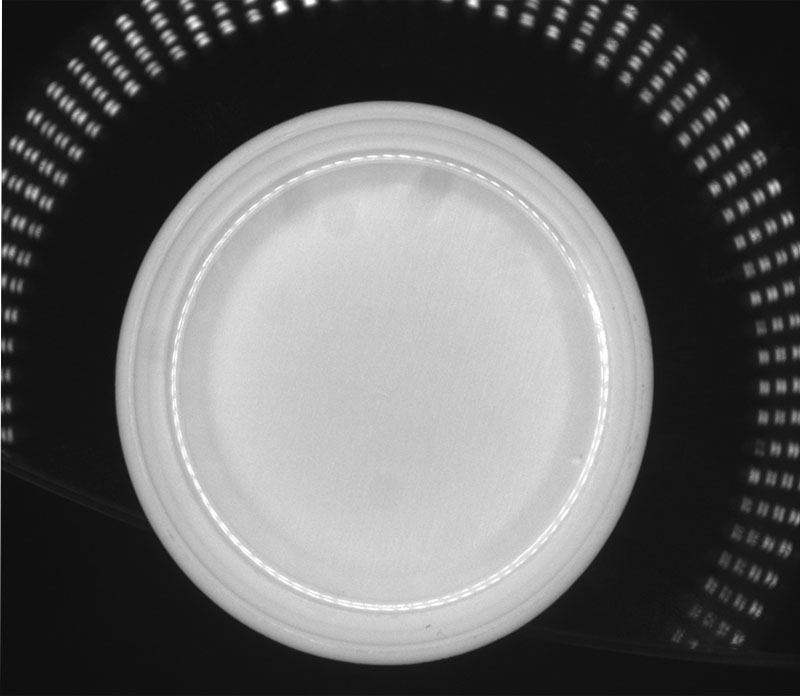

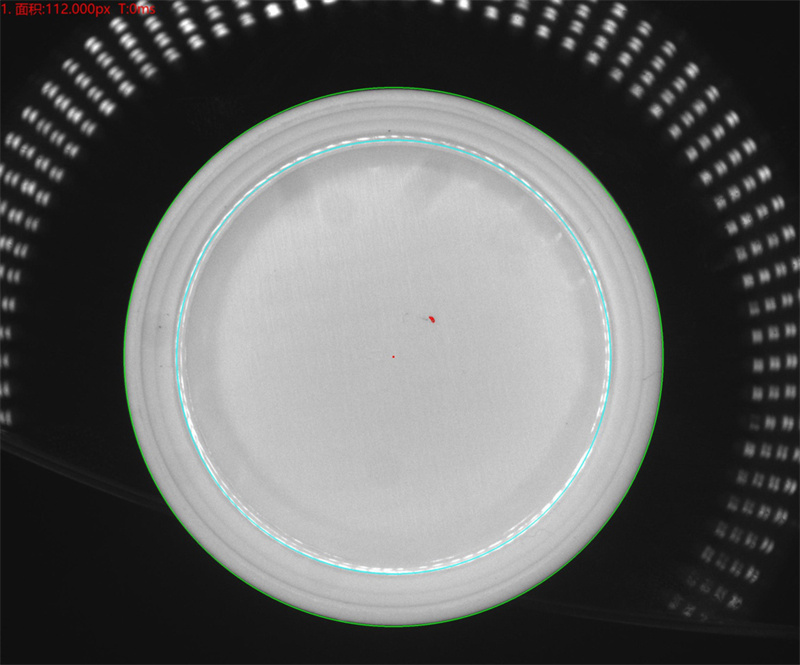

Top detection

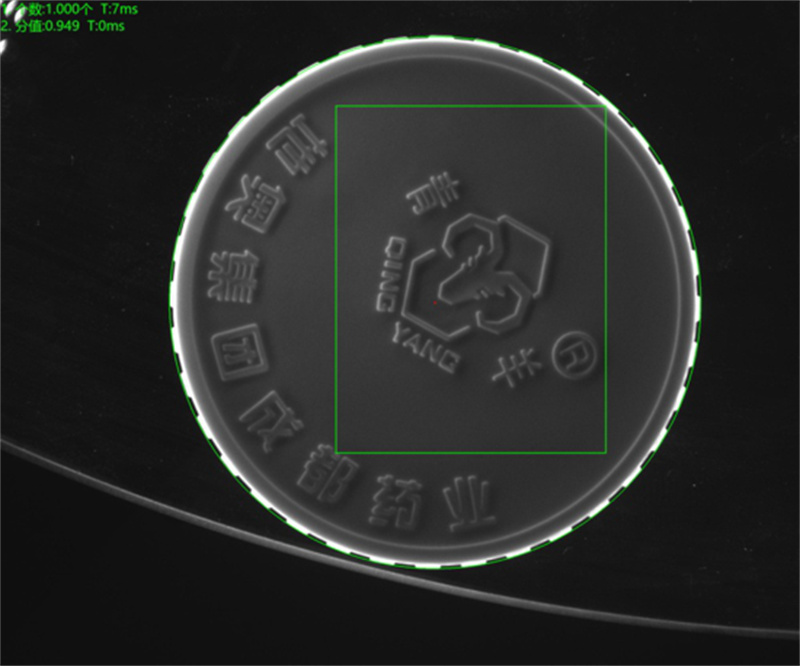

Top positive light good product original image: OK —

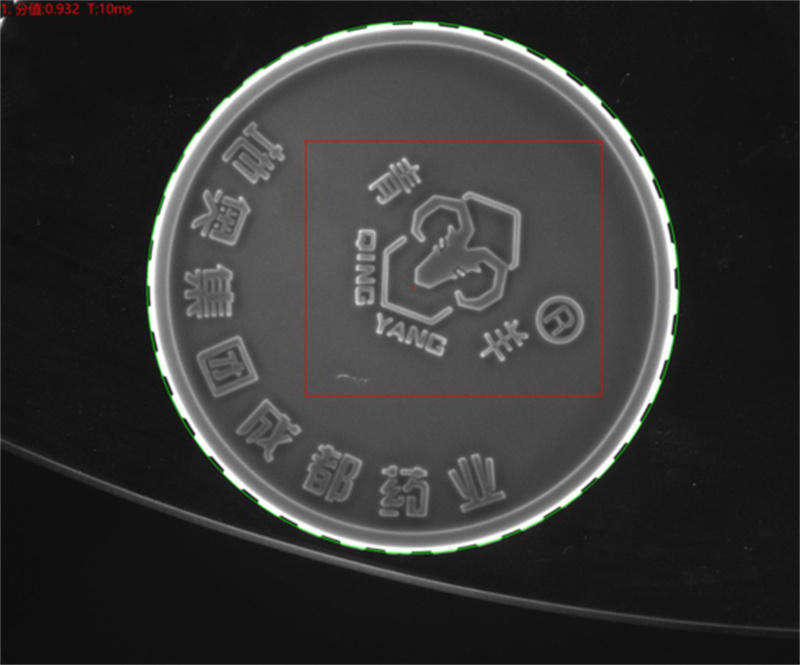

Top positive light defect product analysis image: NG cause of defect: black spot on the top —

Top positive light good product original image: OK —

Top positive light defect product analysis image: NG cause of defect: black spot on the outer wall —

System installation requirements

Equipment placed in the inspection space: In the assembly line side of the installation of Intsoft vision inspection system alone, you need to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius.

Air humidity: 90% RH or less.

Electronic interference: Provide a place with less electronic interference for the equipment.

Power supply: AC 220V, 50Hz, power consumption <1KVA