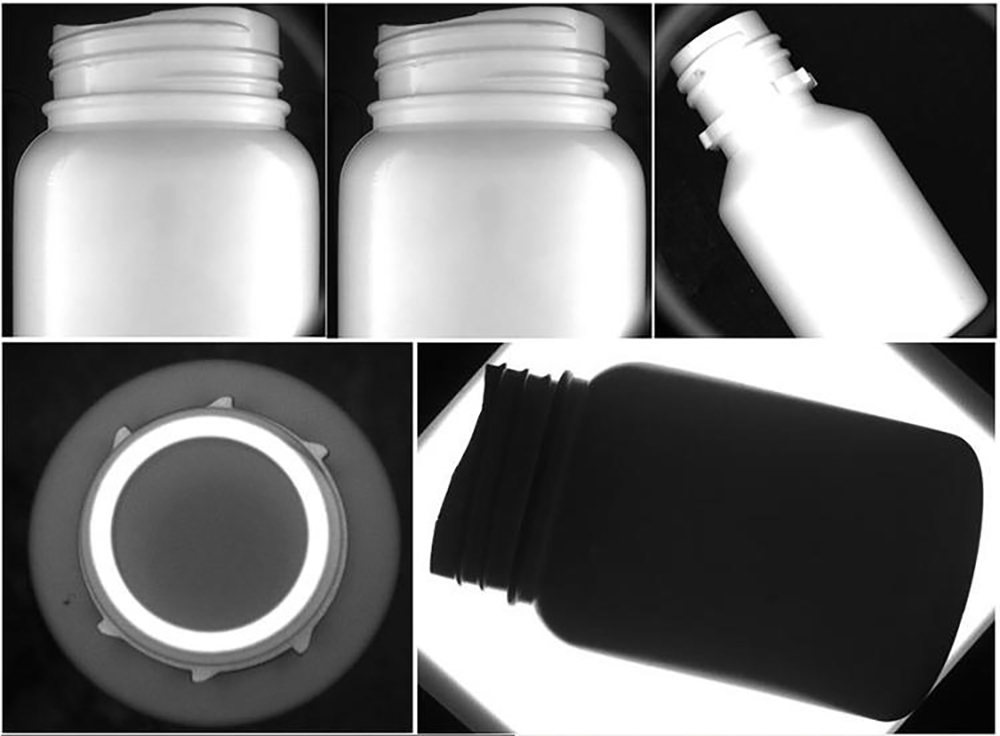

PE bottle containers of medicines must be of high quality because they must come into contact with medicines, and it is important to ensure that the bottle material does not cause contamination of medicines. Therefore, extra strictness is required in the production of these PE material medicine bottles.

The application of visual surface defects allows the production of PE medicine bottles with a pass rate of more than 99.9%, making the quality inspection during the production of medicine bottles simple and efficient. It can scan the surface and accurately identify whether the material used to make the bottle is abnormal or not, whether the bottle is perforated or not, etc.

Following is the medicine PE bottle defect detection process share by Intsoft Tech

Project Requirements

1. Equipped with a conveyor device, through the sorting facilities, bottles enter the inspection equipment for full inspection and rejection of defective products.

2. With deep learning capability and self-maintenance and upgrade function, continuously accumulating data to achieve the rejection accuracy rate tends to 99.97% capability.

3. Realize all-around 360° bottle detection, and display the detection results in real time.

System function:

1. Automatic online detection of bottles with or without defects.

2. Automatic rejection signal output.

3. Real-time statistical detection data, accurate record of current production situation.

System features:

1. Detection rate: 99.97% defective product detection rate.

2. Medicine bottles can be detected correctly no matter how they are rotated on the detection platform.

3. No contact, will not cause 2 times pollution.

4. Modular software operation, easy to learn, the operator takes ten minutes to get started.

5. Applicable to any shape label detection, according to different product models, the establishment of different engineering files, and switching the program in 10 seconds is available.

6. Visualization monitoring and real-time visibility of the current detection situation.

7. The system can be statistical data, detection data information can be docked . Enterprise industrial information systems can also analyze data to identify equipment failure locations.