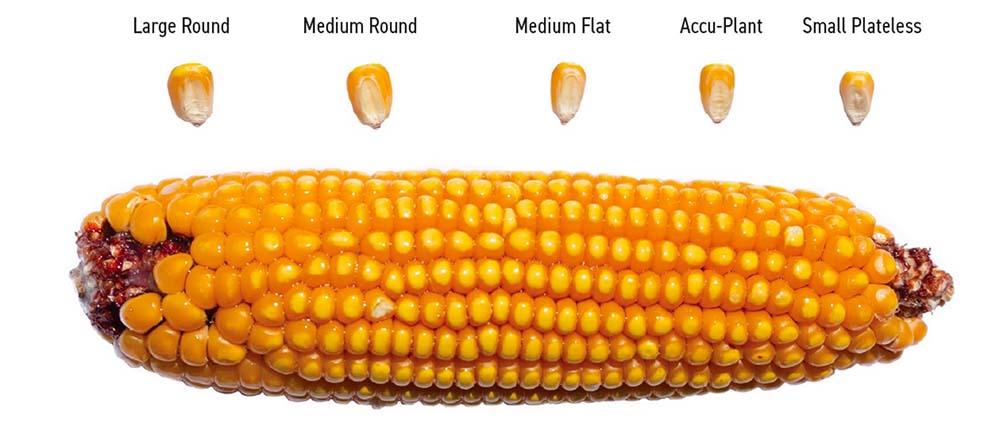

When we buy groceries at supermarkets such as Walmart and Costco, we will find that the same crop, such as corn kernels, will be priced differently depending on the quality. How can such a huge amount of corn kernels be sorted by quality? Of course, it is not sorted manually, but by machine vision. Through high-definition cameras and intelligent algorithms, the size, color, shape and other appearance indicators of each corn kernel can be monitored in real time, and compared with the standard template for analysis. This can not only quickly detect unqualified products, but also generate detailed detection reports to provide a basis for subsequent grading and classification.

Intsoft Tech’s intelligent vision system for agriculture can simulate the human eye for non-destructive visual recognition detection, and make detection more efficient and accurate through image acquisition, image preprocessing and other technologies.

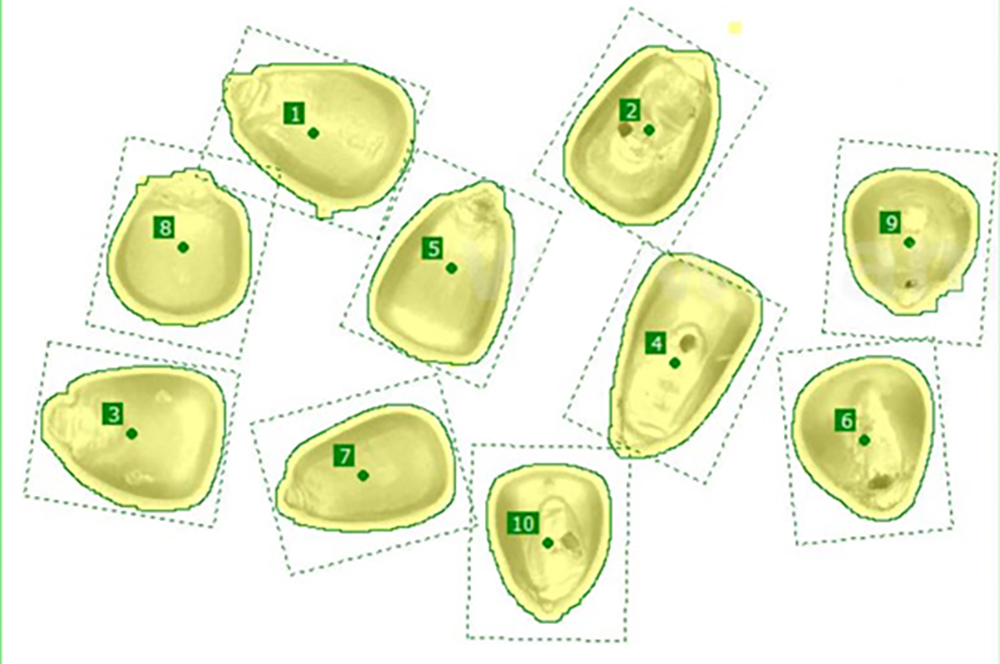

The detection principle of this solution

According to Intsoft Tech machine vision software function, multiple image segmentation of corn kernels is realized, and the pre-processing operation is performed. The software function of plaque curing film and plaque counting is dragged to realize corn worm hole detection, corn black bud detection, corn mildew detection, corn damage detection, etc., so that the detection effect of image information enhancement is more accurate, and the quality of corn is distinguished from the appearance characteristics, color, texture and other information of corn.