Automatic optical inspection (AOI) technology is mainly used in the manufacturing industry and plays an indispensable role. Its main purpose is to improve product quality and production efficiency.

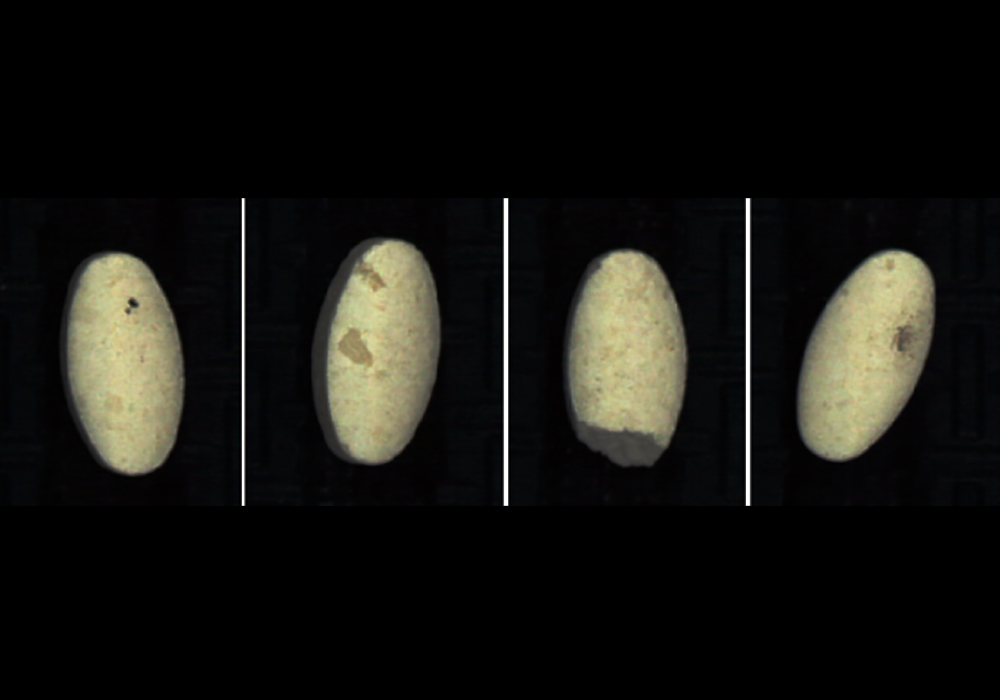

First of all, the core function of the AOI system is to accurately detect various defects in the manufacturing process. These defects may include missing or misaligned parts, surface cracks and discoloration, holes, and other imperfections that are difficult to detect with the naked eye. In contrast, manual visual inspection is easily affected by fatigue, distraction or subjective bias, and it is difficult to maintain a high degree of consistency. The AOI system can use high resolution cameras and advanced computer vision algorithms to quickly and accurately identify various defects, providing strong support for quality control.

Secondly, the AOI system can greatly improve production efficiency and capacity. Compared to manual piece-by-piece inspection, the AOI system’s inspection speed is much faster and can achieve continuous and uninterrupted real-time monitoring, significantly increasing the manufacturer’s overall output. At the same time, the AOI system can also reduce labor costs and minimize rework and waste caused by defects, thereby helping manufacturers save a lot of operating costs. This automated detection method can not only improve product quality, but also significantly improve overall production efficiency.

Finally, the AOI system can also provide enterprises with valuable manufacturing data and analysis support. They generate comprehensive data including defect patterns, production trends and quality indicators. This data can be used not only for root cause analysis and preventive maintenance, but also to help manufacturers make more data-driven decisions to continuously improve overall equipment efficiency and production competitiveness. In addition, the data collected by the AOI system can also provide an important foundation for the enterprise’s intelligent manufacturing and Industry 4.0 transformation.