Industrial Intelligence Cannot Be Separated from Visual Inspection, Accuracy Improvement Is Key

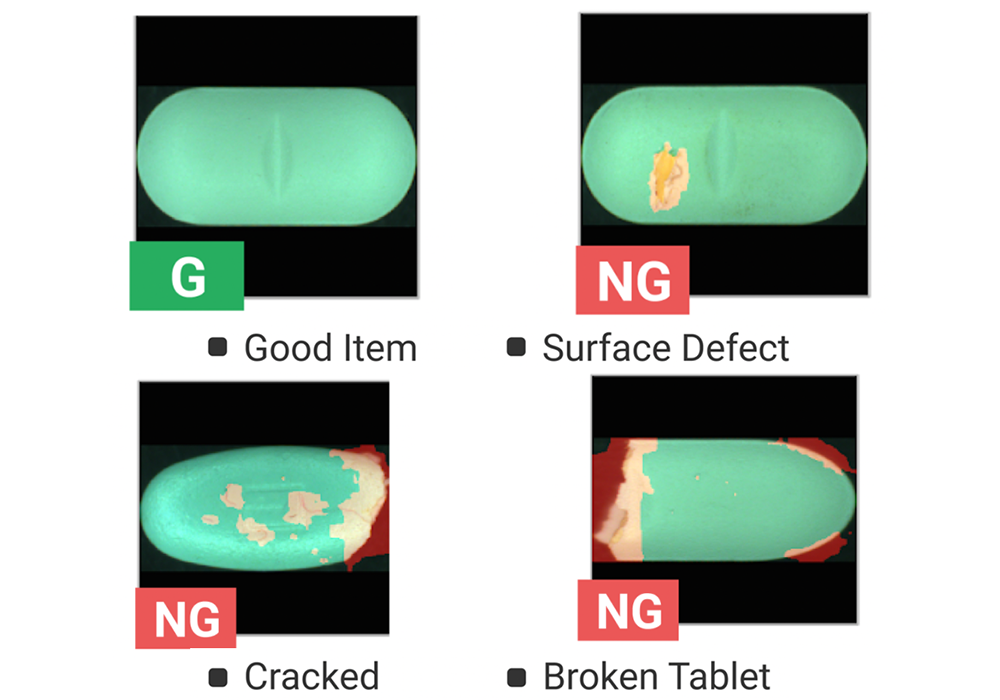

Visual inspection is a key part of the industrial production process, requiring accurate and rapid identification of defective parts.

For a long time, this step of analyzing and inspecting products usually requires human eye recognition, which requires systematic training of inspectors. Qualified visual inspectors use a combination of identification knowledge and skills.

Early studies have shown that the error rate of manual visual inspection is usually 20%-30%, some of which is due to operational errors, but also because their own operating space is limited, so errors can not be avoided. Although the probability of error can be reduced by regular training in manual labor, it still can not be completely avoided.

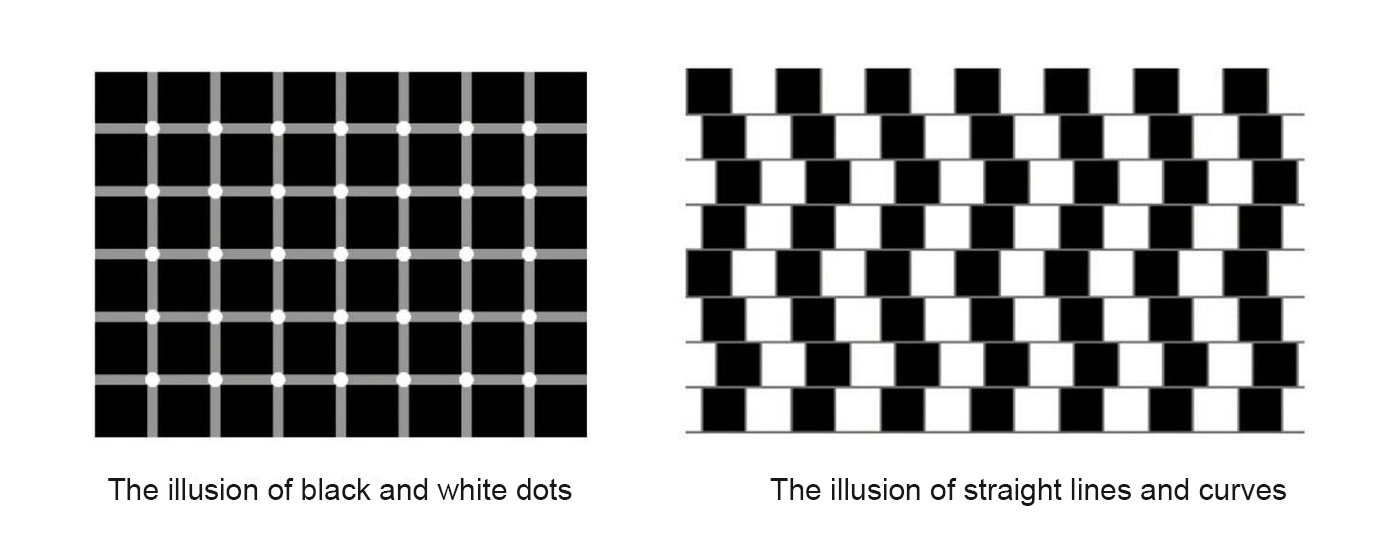

There are also inherent limitations in relying on manual visual inspection. The human eye, although much more advanced than any camera, can still be “fooled.” For example, when we see a pattern like the following, it creates a different illusion.

The inability of the human eye to make accurate measurements and the increase in labor costs for companies make it difficult for traditional manual vision inspection to cope with new requirements. In addition, visual inspection of nuclear power plants, aircraft maintenance, medical equipment and other special industries in the critical field. Once something goes wrong, the consequences can be catastrophic. Therefore, relying entirely on traditional manual visual inspection is obviously much more limited.

Now, AI-based industrial vision inspection has a wider visual spectrum and can recognize more diverse types. In the case that the system is fully trained to learn, it can continuously and accurately measure the inspection object in batches. The error rate and cost are greatly reduced while efficiency is greatly improved. In addition, the task can be easily accomplished in some hazardous or harmful environmental conditions, solving the problem of improper manual inspection in some operating spaces or environments.

The vision inspection system based on Intsoft’s AI technology can not only overcome the above problems, but also automate vision inspection without human intervention throughout the entire process. This makes the inspection efficiency and effect greatly improved.

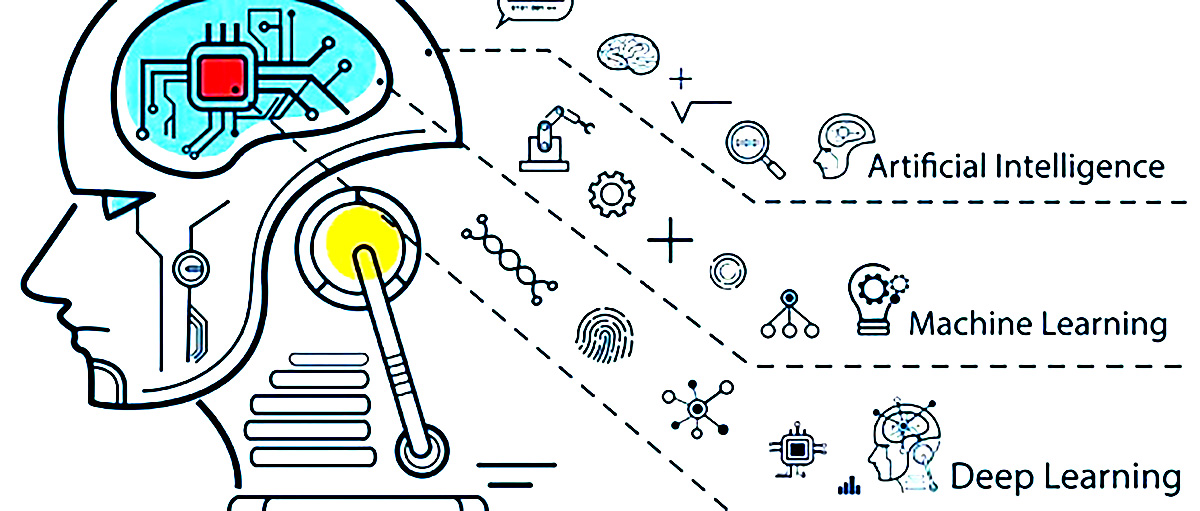

Intsoft AI utilizes deep learning technology to make the whole process smarter

Deep learning techniques use neural networks containing thousands of layers to simulate human thinking, which in turn can achieve effects such as distinguishing normality from complex patterns and filtering out anomalies and discrepant features.

Thus, deep learning well combines the adaptability of human visual detection with the speed and robustness of computer systems.

In addition, due to the underlying support of cloud computing, large-scale computing resources can be dispatched at low cost and elasticity can be achieved through the use of Intex AI, so that deep neural network computation at multiple levels can be smoothly implemented to emulate the neural network processes in the human brain.

This gives production technology a miraculous new ability to recognize images, distinguish trends, and make intelligent predictions and decisions.

Starting with the core logic developed from initial training, deep neural networks can continue to iterate and optimize their performance with new images, speech, text, and more. Machine vision technology combined with it can easily identify details of various subtle objects that are not visible to the human eye, resulting in higher reliability and lower detection error rates.

Therefore, when the two are combined, this deep learning-based image analysis can be used to cope with many more complex visual inspection needs, with results that could not be achieved by manual visual inspection or simple machine vision systems in the past.

AI visual inspection creates tremendous value, Intsoft Technology LLC can help businesses do more

With the support of AI technology, industrial vision inspection plays a greater role: faster resolution efficiency, more reliable resolution results, more accurate measurement standards, more flexible measurement environments, able to adapt to hazardous environments and so on.

In the transformation from industrialization to intelligence, AI and cloud computing are playing an important role in promoting. Intsoft Technology LLC continues to create value for customers through its own AI capabilities.

In the future, Intsoft will provide more reliable solutions for the development of industrial intelligence.

If your industrial production line, due to the use of traditional machine vision, or the efficiency of the quality inspector, can not meet the requirements you want, then you may wish to talk to us, we will listen to your views, from a professional point of view, to give you a tailored design a set suitable for your program.