Tire surface defect detection case

Our client, one of the tire suppliers for Xiaomi’s new energy vehicles, found us to upgrade their production line and replace their original equipment with Intsoft’s machine vision inspection equipment. The vision equipment they have used for many years has insufficient detection accuracy, resulting in missed detection and false detection. Therefore, after investigation, it was decided to use Intsoft Tech’s advanced machine vision technology to comprehensively detect the tire surface and eliminate various minor defects.

Project requirements

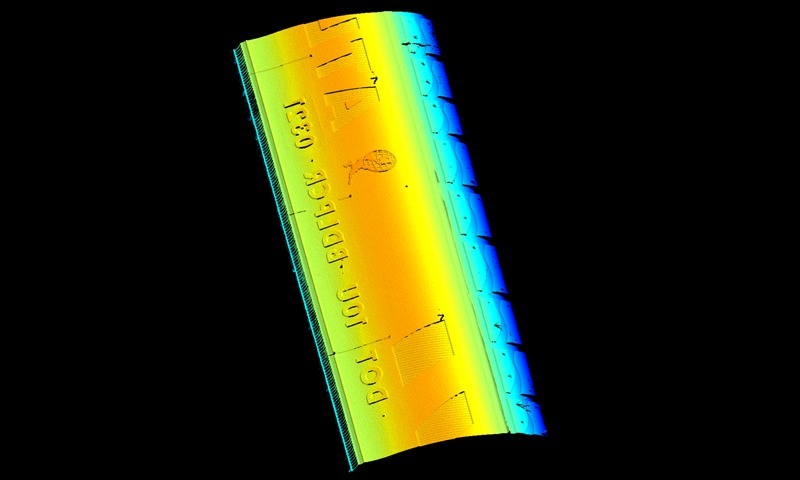

1. Ability to quickly and efficiently scan tire surfaces and generate high-resolution three-dimensional height maps.

2. Reliable detection of various minor tread and sidewall defects, such as bulges, dents, etc.

3. The detection accuracy must reach submillimeter level to ensure that the problem defects are not missed.

4. Achieve a fully automated inspection process, improve efficiency and eliminate errors caused by manual operation.

5. Equipped with a friendly human-computer interface, it is convenient for operators to monitor and manage.

Solution

Multi-angle 3D scanning equipment

We equipped this project with a set of multi-angle 3D scanning devices. It uses a high-precision structured light scanning sensor to quickly collect three-dimensional high-definition tire surface data with a scanning resolution of up to 0.1mm.

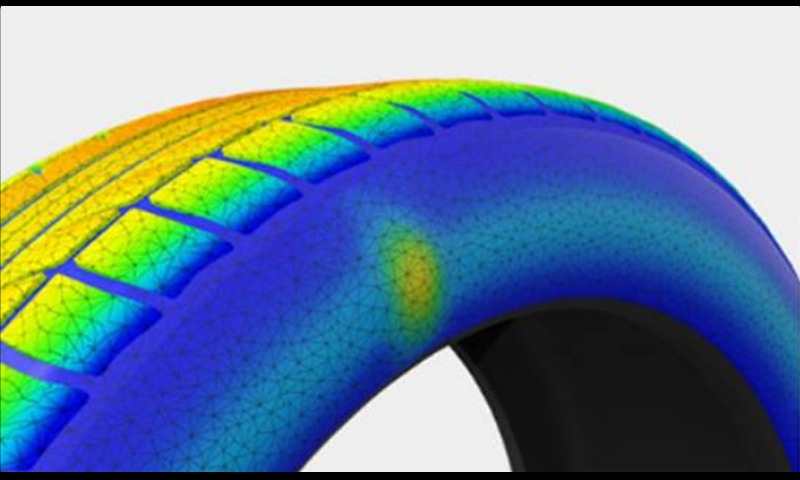

Intelligent defect detection algorithm

According to the characteristics of the tire surface, we have developed an intelligent image processing algorithm based on deep learning. The algorithm can accurately extract various types of tiny defects, such as bulges, dents, cracks, etc. from 3D scanning data, with a detection accuracy of up to ±0.05mm.

Fully automated detection process

The entire detection process is fully automated. The operator only needs to place the tire on the test platform, and the system can automatically complete the entire process of scanning, defect detection, data analysis and report generation.

Intelligent human-computer interaction

We have equipped the system with a touch screen human-computer interface, so that the operator can intuitively view the test results and flexibly adjust the test parameters. The system also supports remote data management and fault diagnosis functions.

Working principle

Tire placement: The operator places the tire on the automatically rotating test platform.

3D scanning: The multi-angle structured light 3D scanning device begins to fully scan the tire surface and capture high-definition three-dimensional image data.

Defect detection: The intelligent algorithm analyzes scanned data to quickly and accurately identify various types of tiny defects, such as bulges, dents, etc.

Results display: The human-computer interface displays the test results in real time, including defect location, size and other information. The operator can confirm and adjust the results.

Report generation: The system automatically generates a detailed test report, recording the characteristic data of each defect. The report can be printed or exported to an electronic file.