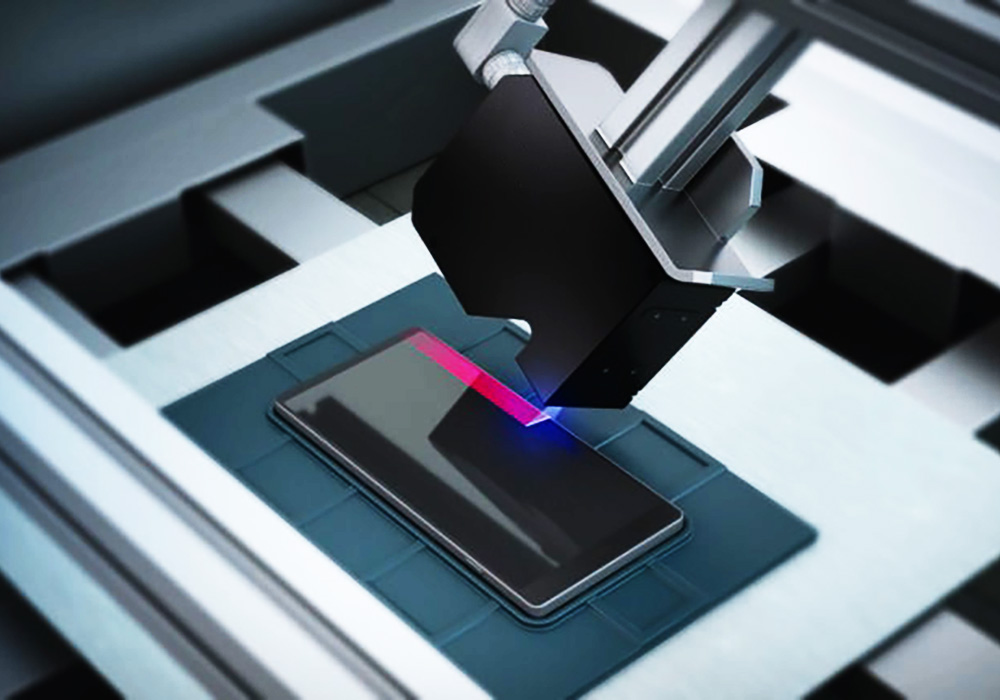

Deep Learning+ Glass Cover Appearance Defect AOI Inspection Solution

Adopting multi-light source strobe control, multi-angle human eye simulation, multi-spectral imaging design, multi-channel image analysis technology independently developed by Intsoft Technology LLC, it realizes fully-automatic and intelligent inspection of various kinds of point and line appearance defects of cell phone glass cover plates, solves the problems of high labor cost, high difficulty of inspection, unstable yield rate and so on in the inspection link in the production process of the glass cover plate, effectively improves the quality of the products and production capacity, and helps customers to Improve product output and save cost.

At the same time, we analyze the defect data in multiple dimensions to find out the problems exposed by each process segment, help customers optimize the process, and gradually improve product yield.

- Appearance inspection of white glass cover plate

- Finished Glass Appearance Inspection

- Appearance inspection of laminated glass cover plate

- 3D Glass Cover Appearance Inspection

Common defects include scratches, unevenness, edges chippings, holes chippings, black spots, foreign objects, hairs, dirt, handprints, etc.

The use of Intsoft Technology’s vision inspection system, can be effective on cell phone glass cover all kinds of dotted, linear appearance defects in fully automatic intelligent detection, to solve glass cover production problems.

Rapid detection speed

Using FPGA for algorithm optimization and acceleration, the fastest TT (beat) system detection is 1S/pcs.

The production capacity is 3600 pcs/h, more than 30 times higher than traditional detection.

High detection accuracy

The system adopts 8K, 16K high-resolution line scan camera, stable detection of the smallest defect size of 10μm.

Low omission rate

The omission rate is significantly lower than manual inspection, improving product quality.

Effective control of scrap generation.

Low false detection rate

Adopts a unique combination of multiple light sources, multiple angles, and multiple brightness imaging modes.

The algorithm model accurately identifies falling dust, effectively reducing the false detection rate.

Strong stability

The unified detection standard of visual inspection equipment eliminates the subjectivity of manual inspection.

Detection results are objective, stable and reliable.

Multiple application scenarios

Widely used in cell phones, tablet PCs, notebook computers, car displays, LCD TVs and other application scenarios.

Fast deployment

Can run multiple AOI inspection equipment on site, quickly deploy online, and optimize debugging methods to shorten the trial cycle.