As a traditional fermented food, the appearance quality inspection of bottled kimchi is an important step to ensure its quality. For example, if the quality of the bottle cap is unqualified, it may cause the liquid inside to leak and spoil the kimchi. Through machine vision technology, canned and bottled food manufacturers can quickly and accurately conduct comprehensive inspections of the appearance of kimchi bottles to ensure that each bottle of product meets standard requirements.

The visual inspection system can identify whether there are deviations in the shape and size of kimchi bottles. The complete bottle should maintain a standard cylindrical shape, and any deformation and variation may affect the consumer’s visual experience.

The following uses the bottle cap as an example to share the content of the visual inspection.

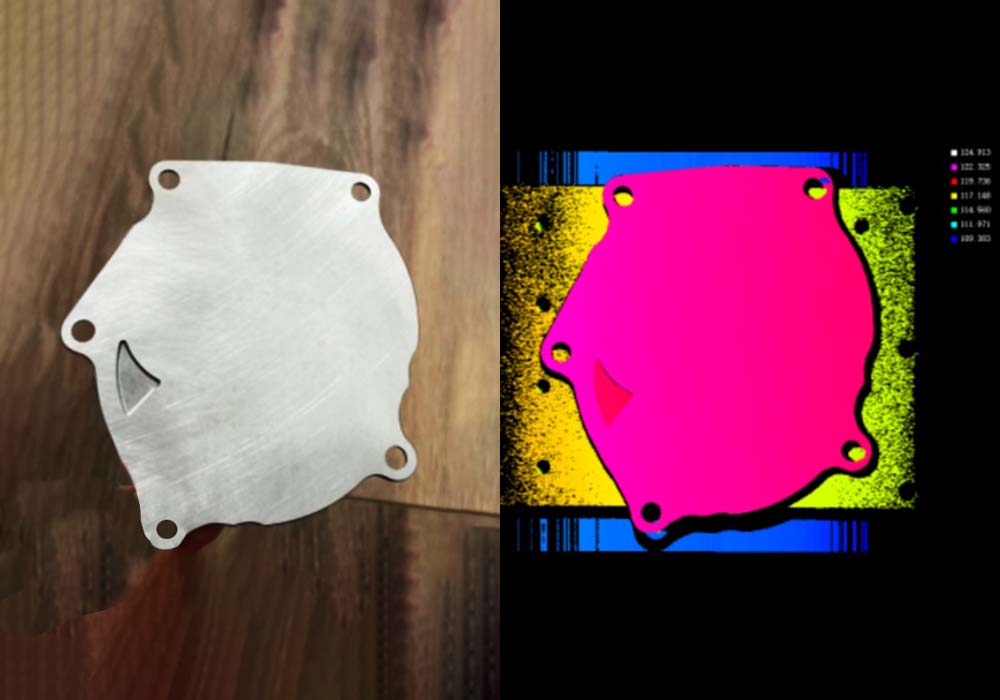

Inspection object:

Inspection difficulty:

Metal caps tend to reflect light when illuminated, causing scratches to be unclear or interfered with by the patterns on the caps.

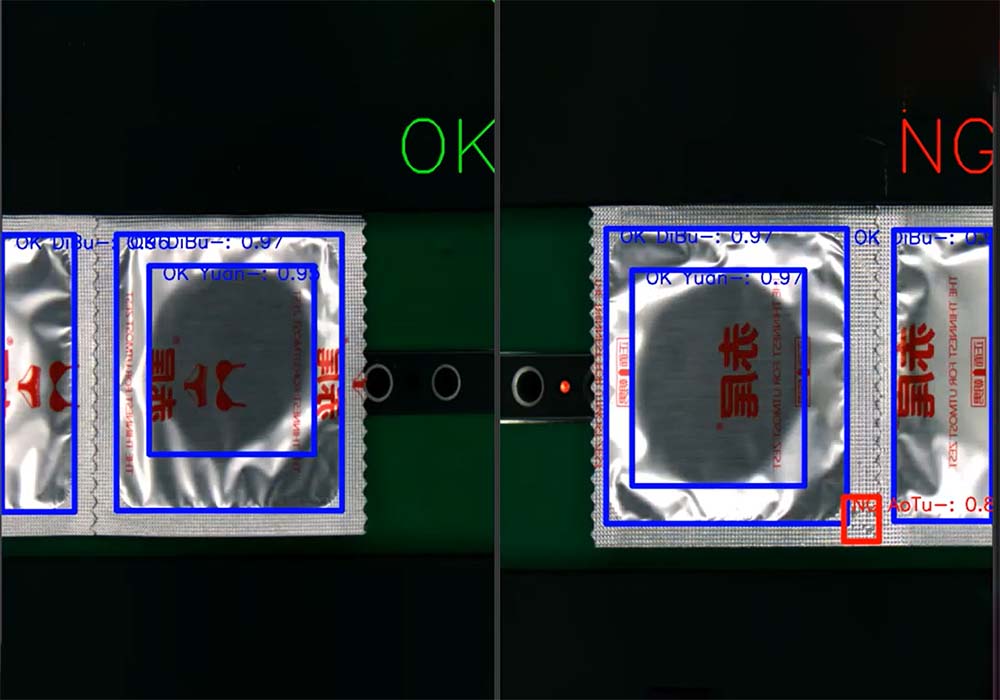

Inspection requirements and result:

It is required to detect whether there are scratches (greater than 1×1mm) on the surface of the bottle cap. Through inspection of the visual inspection system, the inspection results are as follows:

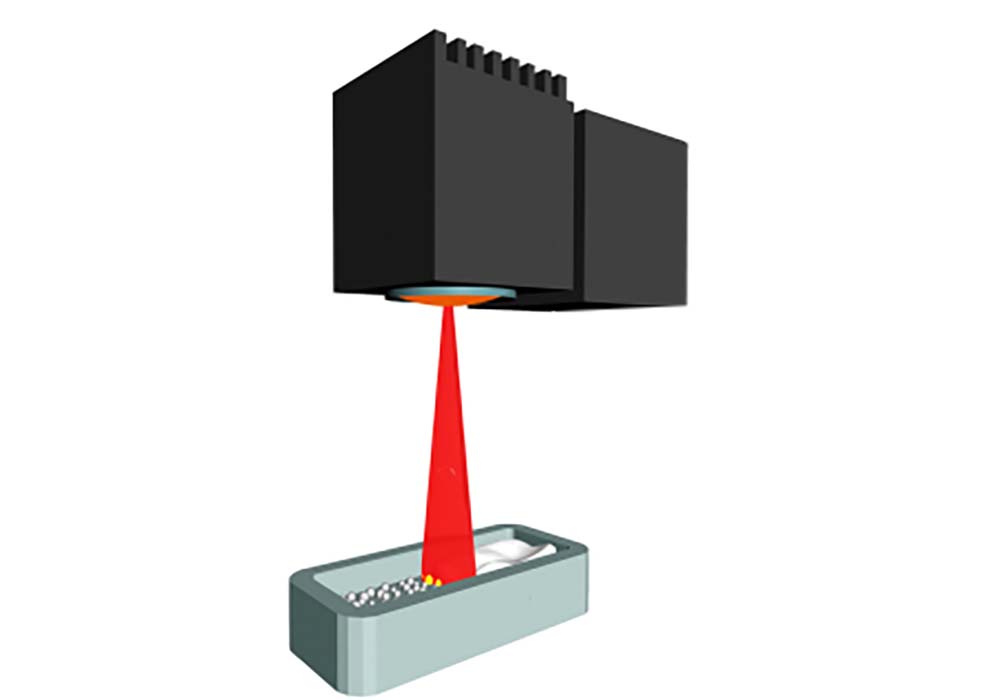

By using a low angle light source, scratches are highlighted, forming a sharp grayscale value contrast with the surrounding area. Then, using spot search, scratches can be accurately detected.

The above demo shows that our visual inspection system can determine whether there are scratches on the surface of metal bottle caps by deeply studying image processing algorithms, such as spot search, with fast speed and high accuracy. It can also detect other visual problems such as whether the surface of the bottle cap is coded and whether the code is correct. This method can also be used in other industries to detect object defects.