Intsoft Technology uses the principle of machine vision inspection to provide AI application solutions for dimensional inspection, alignment inspection, appearance defect detection, positional homing, and corrective closed loop control scenarios in the battery manufacturing process, so that your company can no longer have quality concerns in quality control.

Our common inspection items:

Size Inspection

Alignment Inspection

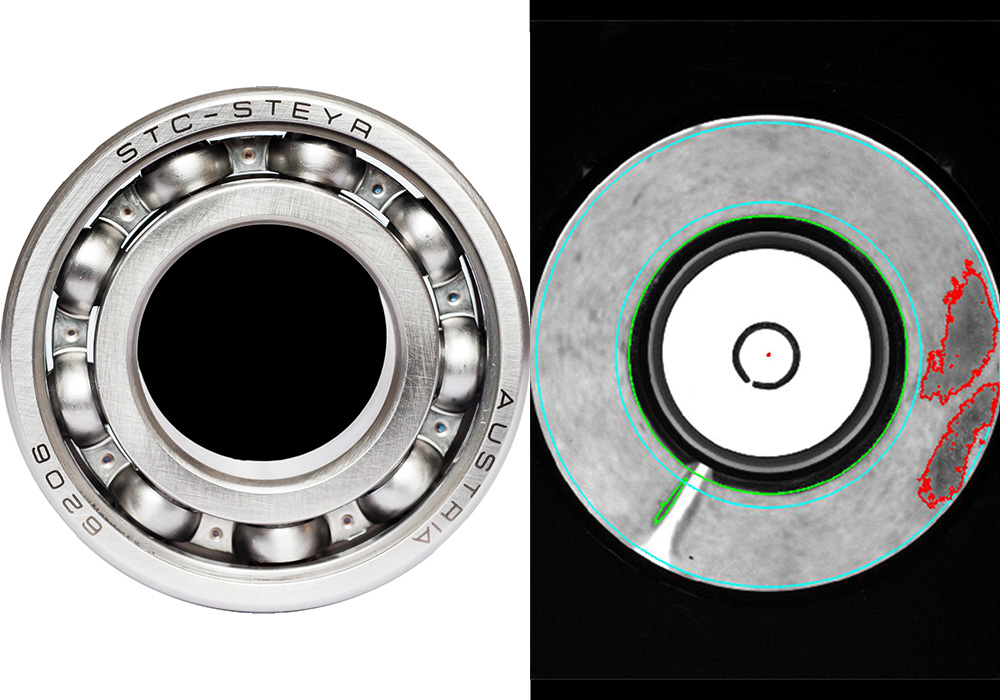

Appearance Defect Detection

Position correction

Closed loop control for offset correction

Diaphragm Visual Inspection

Cast line base film quality inspection slitter for CCD appearance defect detection.

Pouch cell visual inspection

Prismatic cell

Cyclinder cell

And some related processes:

Coating machine CCD size inspection and correction, appearance defect detection

CCD appearance defect detection mixer

Slitting machine CCD size+ deskew+ appearance defect detection

Die cutting machine CCD size inspection

Stacker CCD size inspection and correction, alignment detection

Our Advantages

Fast speed:

Adopting heterogeneous computing technology, based on FPGA, GPU, CPU and other basic hardware, in-depth hardware and joint software optimization, to provide the computing power required for real-time computation of ultra-high-speed application scenarios.

High accuracy:

The use of Intsoft Technology’s patented light source technology and 8K/16K high-definition line scan camera, according to the type of material being inspected, width, production speed and other characteristics of the optimal combination of programs to provide a clearer image of the smallest detection defects up to 10μm

Functionality:

- Size detection

- Alignment detection

- Appearance defect detection

- Position correction

- Closed-loop control.

Good stability:

Visual inspection of a unified detection standard can effectively eliminate the human subjectivity of manual inspection, objective detection results, and support for 24/7 uninterrupted work, stable and reliable.

Data intelligence:

Multi-dimensional data analysis function, seamless MES docking, to help enterprises improve the process, to create intelligent factories.

Complete program:

Machine vision solutions for diaphragm production.

Machine vision solutions for flexible pouch cells.

Machine vision solutions for prismatic cells.

Machine vision solutions for cyclinder cells.