Machine vision filling quality inspection

On the pharmaceutical canning production line, another issue that needs to be concerned about is whether the cap is pressed in place after capping? Is liquid medicine enough? Ensure that the bottle is sealed intact and that the vacuum degree in the bottle is guaranteed.

Filling inspection image sensor installation diagram

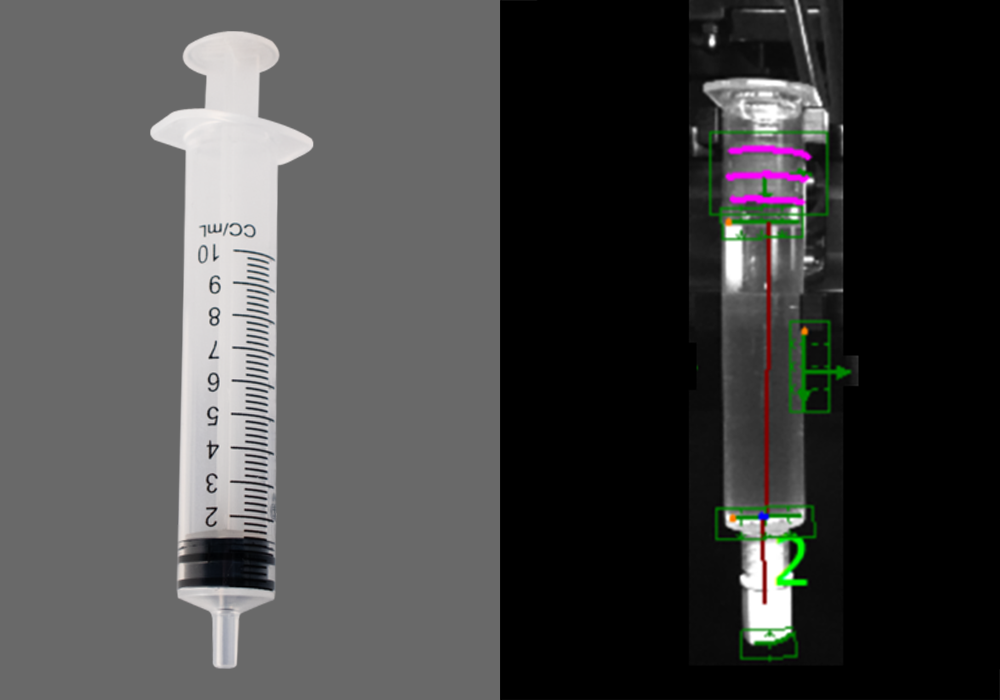

After installing the image sensor in the capping process, the linear tool is used to measure the change in the bottle cap and liquid level in the Y-axis direction to determine whether the bottle cap is installed in place and whether the amount of medicine is correct.

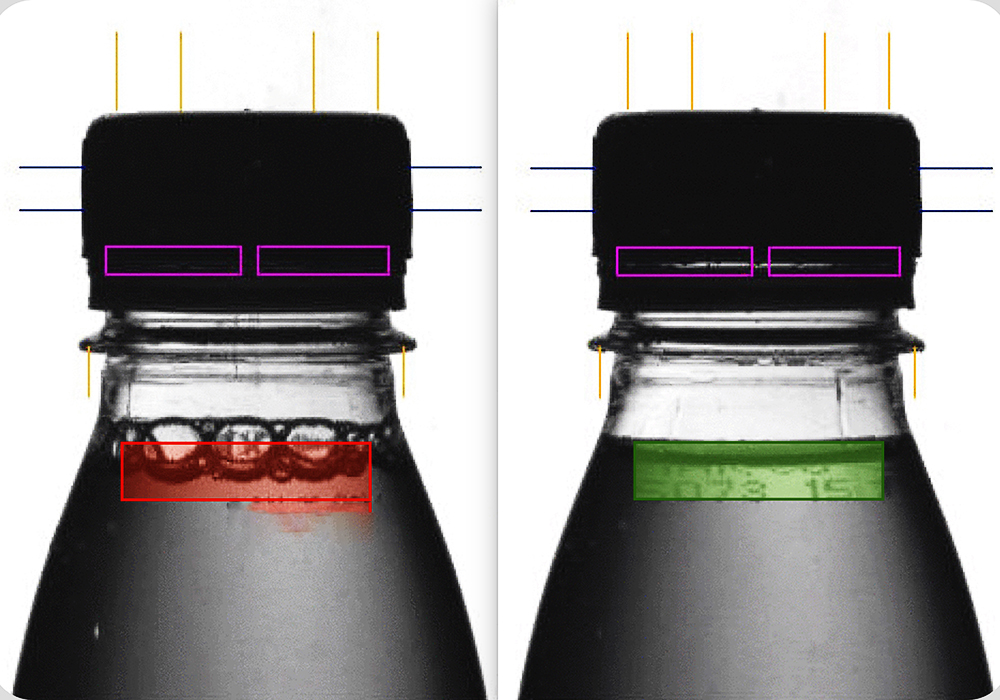

Bottle cap and liquid medicine height detection

By measuring the gap between the bottle cap and the bottle mouth, it is determined whether the bottle cap is installed in place; by measuring the distance between the liquid surface and the bottle mouth, the height of the liquid level is determined. They are all relative position measurements, so they will not be affected by the slight vibration of the bottle on the conveyor belt. After this inspection, it can be ensured that all medicine bottles with incomplete bottle caps and insufficient liquid medicine are eliminated.

The above lists only some of the applications in the food and drug industries. Whether machine vision inspection can be widely used depends on whether food and drug companies know more about machine vision.

Turn on the machine vision feature for manufacturing

Where to install, how to install, how to achieve the best effect, and what specific benefits can be brought, all these need to be continuously popularized and promoted.

Activating machine vision in manufacturing offers many benefits that can significantly enhance productivity, quality, and efficiency. First, machine vision systems enable rapid, accurate and consistent inspection of products, reducing defects and improving overall quality. This, in turn, leads to reduced rework, scrap, and customer returns, ultimately lowering costs. In addition, machine vision can automate various manufacturing processes, such as guidance, measurement, and identification, allowing for faster production cycles and increased throughput. Furthermore, the data collected by machine vision systems can provide valuable insights for process optimization and predictive maintenance, empowering manufacturers to make data-driven decisions and continuously improve their operations. By embracing machine vision technology, manufacturers can gain a competitive edge, stay ahead of industry trends, and deliver high-quality products to their customers.